Auxiliary system used when in customizing jewelries

An auxiliary system and jewelry technology, applied in the field of auxiliary systems, can solve the problems of collision between grinding discs and fixtures, damage to the grinding discs of fixtures, etc., and achieve the effect of avoiding collisions and good processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

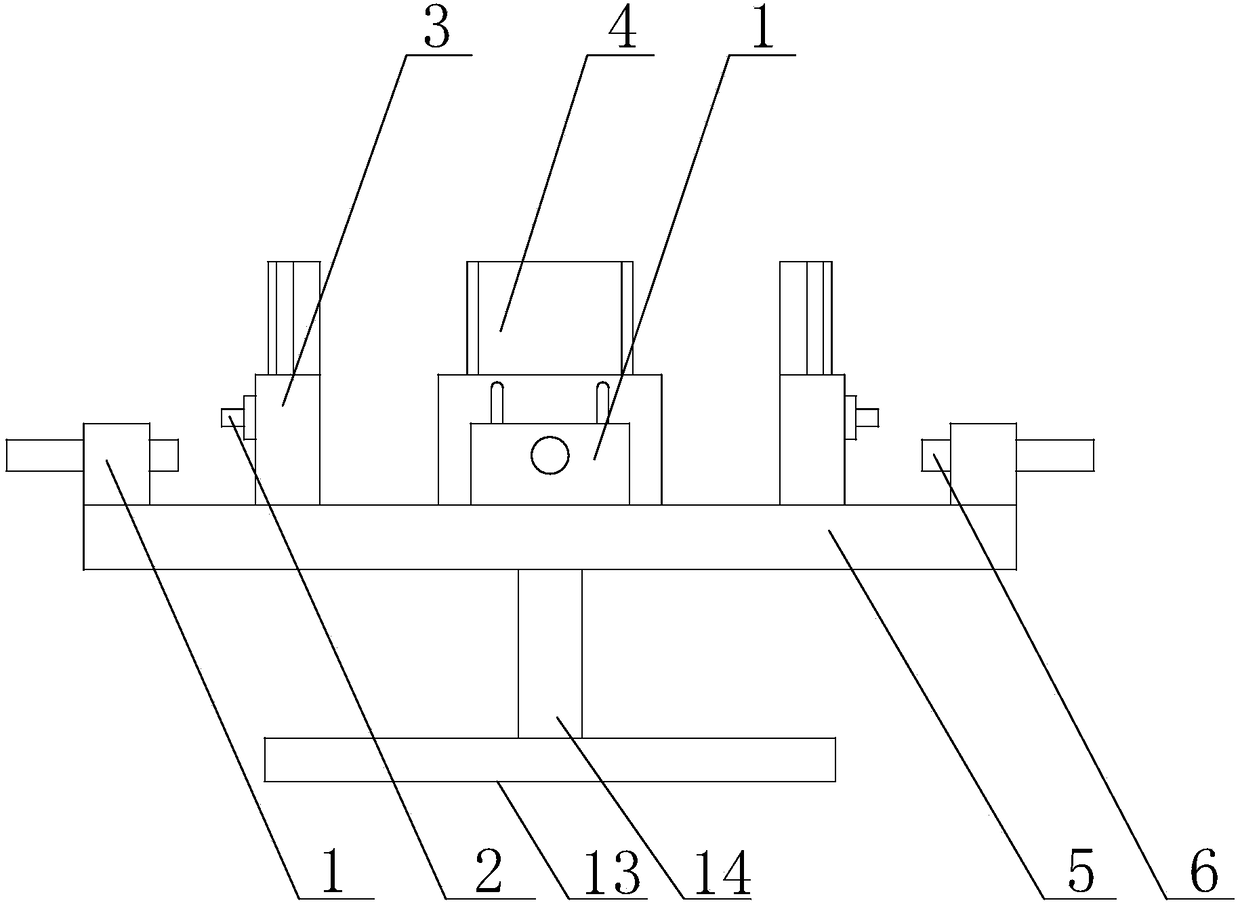

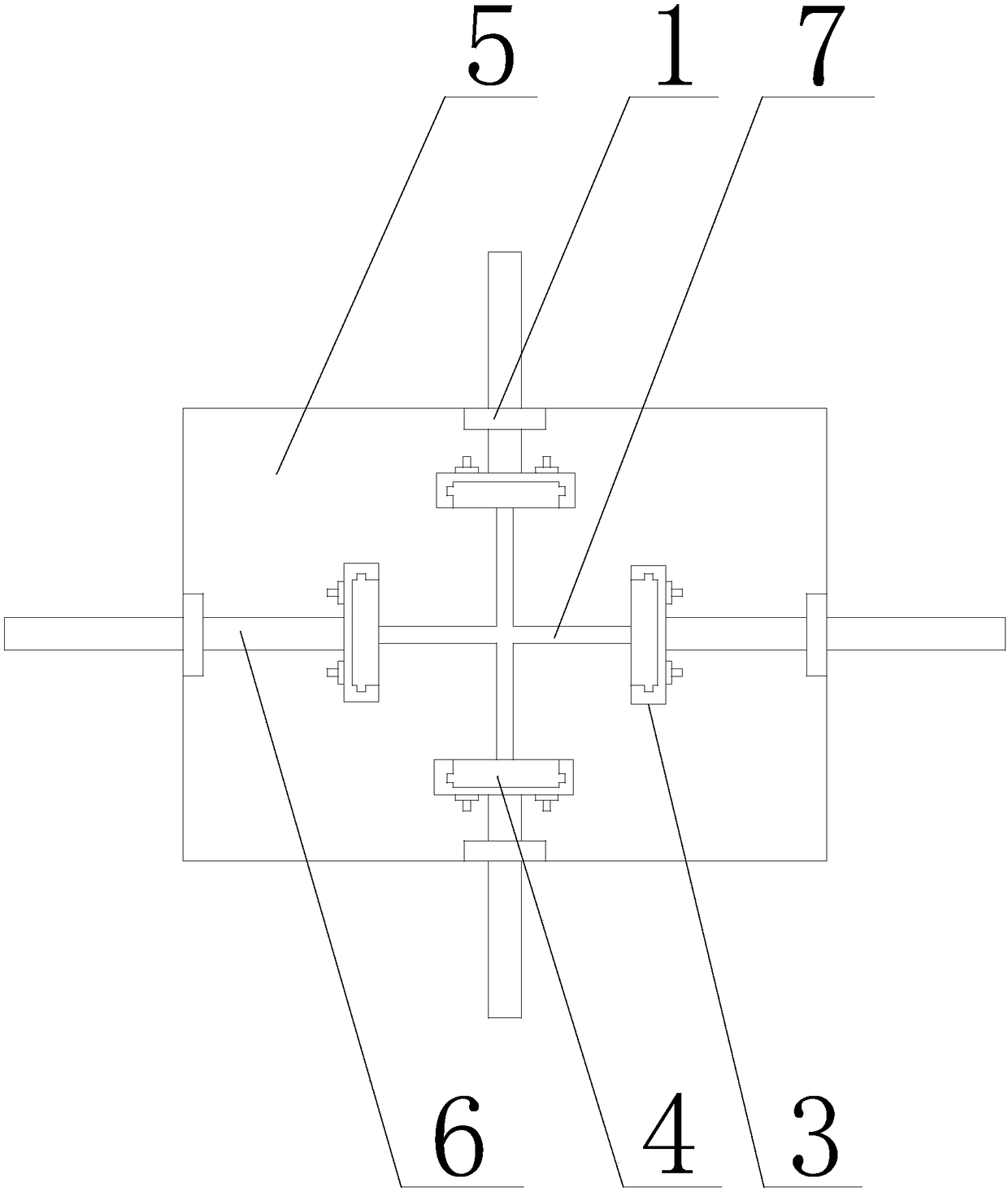

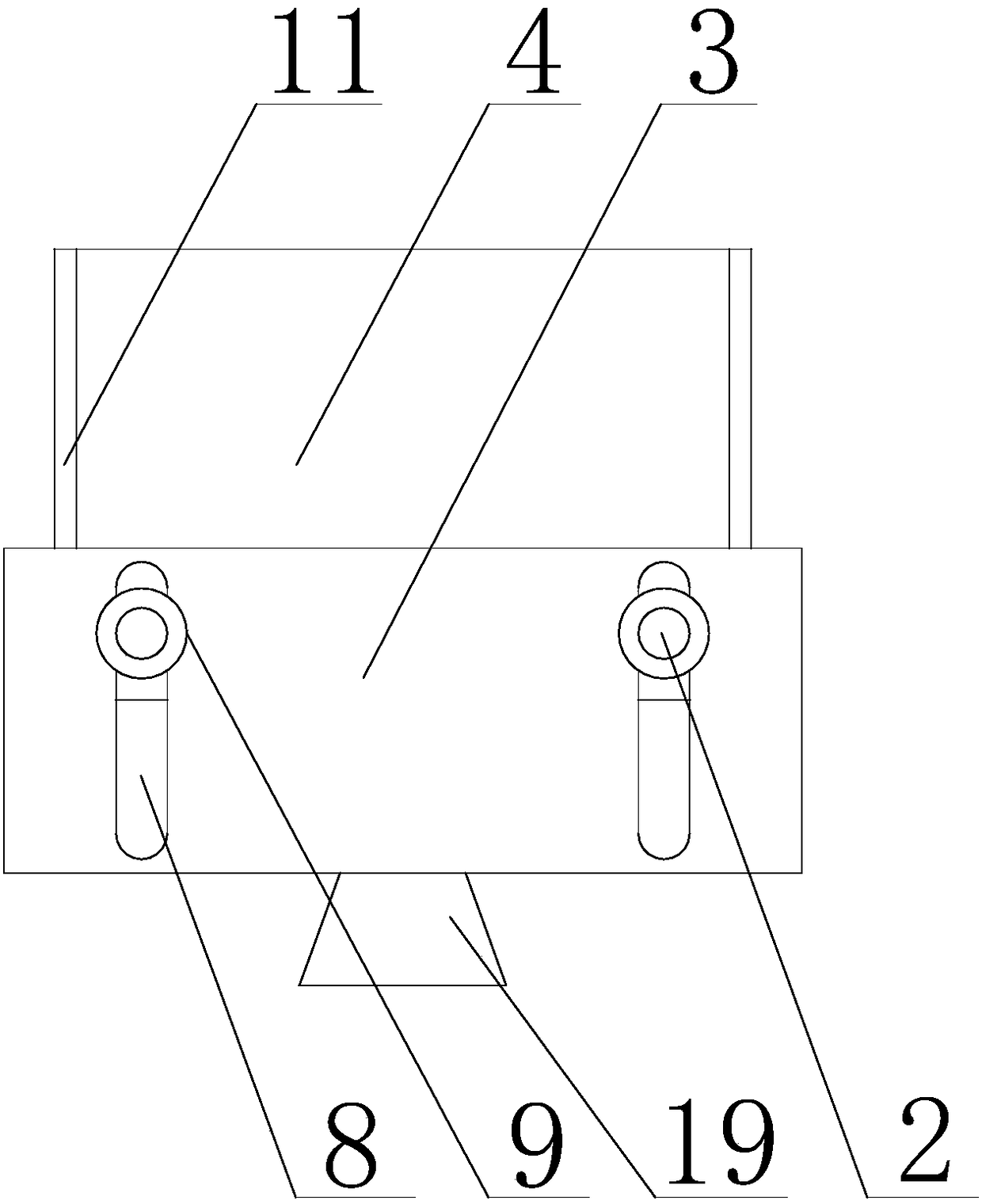

[0025] Such as Figure 1 to Figure 6 As shown, the present invention is an auxiliary system used for jewelry customization, including a support platform 5, the support platform 5 is a rectangular structure, the top of the support platform 5 is provided with two mutually perpendicular chute 7, and two Chute 7 all passes through the central position of support platform 5, and the slide block 15 that matches with chute 7 is all provided in two chute 7, and slide block 15 can move in chute 7, and the top of described slide block 15 The first clamping plate 3 is provided, and the first clamping plate 3 can move together with the slider 15. The set first clamping plate 3 is used to fix the cylindrical jewelry raw material to be processed, so as to prevent the spherical raw material from being polished during the polishing process. Move, the top of the support table 5 is also provided with fixed blocks 1 whose number is consistent with the number of the first clamping plates 3, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com