Machining device for automobile parts

A technology for auto parts and processing devices, which is applied in the directions of cleaning methods using liquids, cleaning methods using tools, cleaning methods and utensils, etc., can solve problems such as low cleaning efficiency, improve aesthetics and cleanliness, and reduce labor. Labor intensity, the effect of enhancing the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Further detailed explanation through specific implementation mode below:

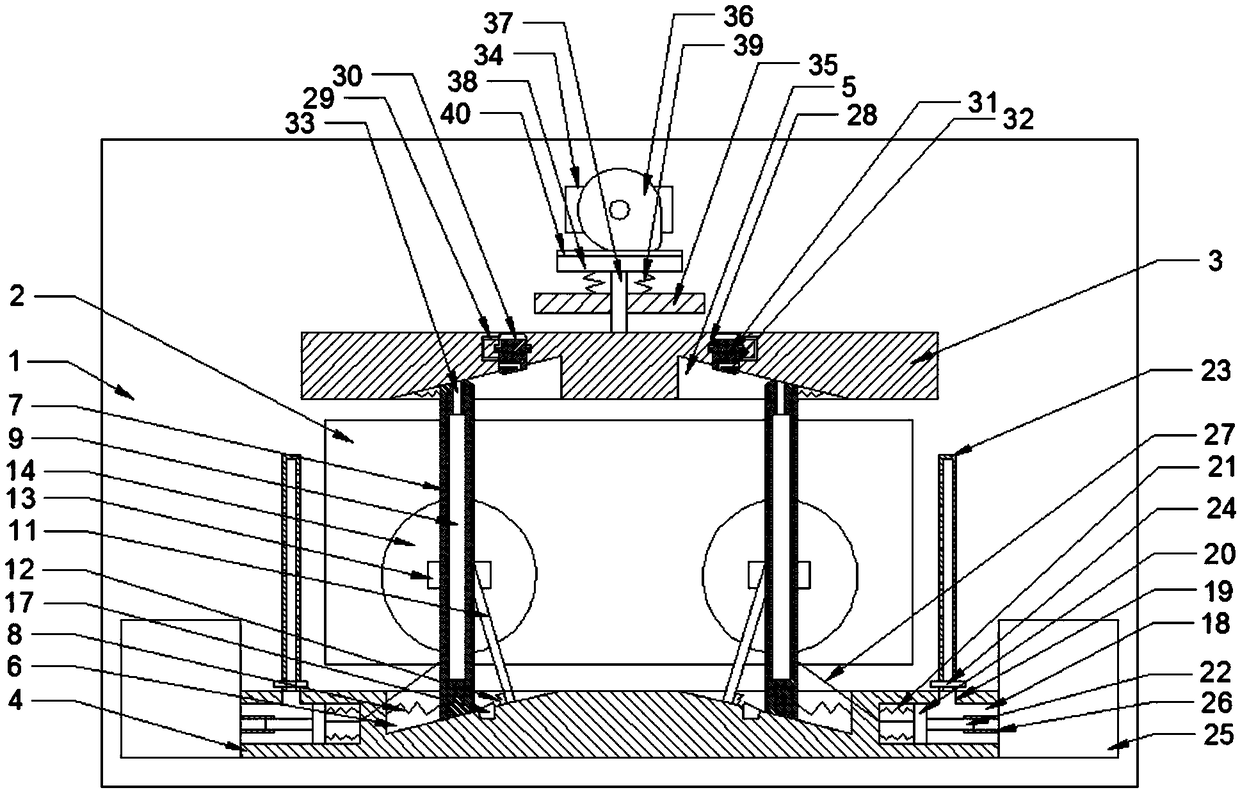

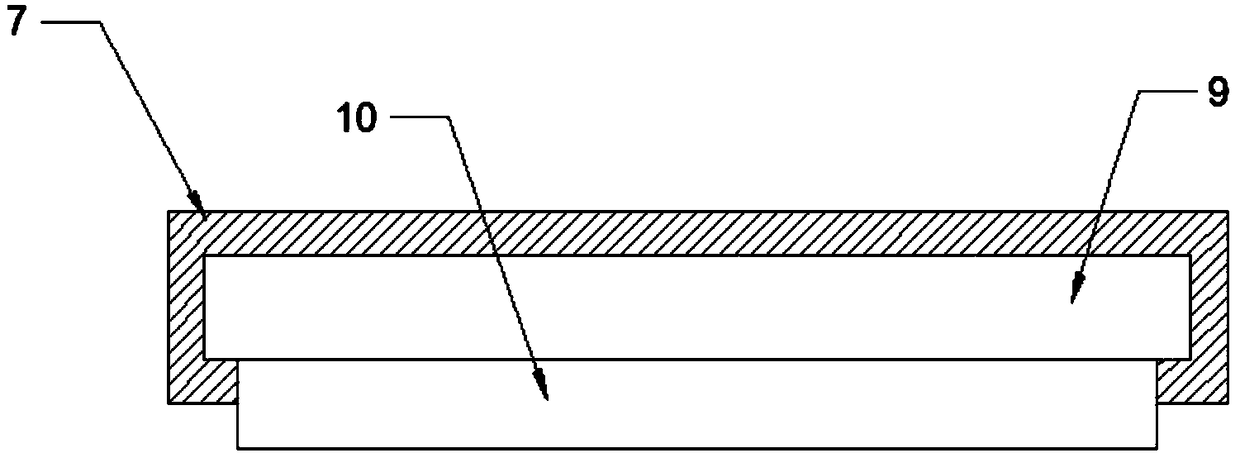

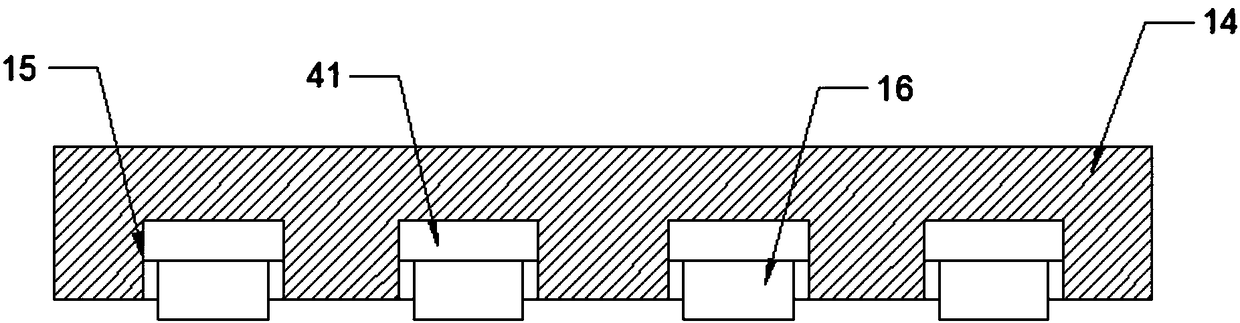

[0019] The reference signs in the drawings of the description include: machine base 1, positioning groove 2, movable plate 3, fixed plate 4, upper chute 5, lower chute 6, wedge 7, first spring 8, cavity 9, First cleaning brush 10, rocking arm 11, second spring 12, first motor 13, turntable 14, groove 15, second cleaning brush 16, trigger switch 17, transverse groove 18, vertical groove 19, slider 20, The third spring 21, blocking block 22, water spray pipe 23, one-way valve 24, water tank 25, water inlet pipe 26, steel wire 27, limiting groove 28, U-shaped hole 29, air bag 30, limiting block 31, L-shaped Hole 32, through hole 33, second motor 34, support plate 35, cam 36, push rod 37, push plate 38, fourth spring 39, rubber layer 40, sponge block 41.

[0020] The embodiment is basically as attached figure 1 Shown: a processing device for auto parts, including a machine base 1, on which a positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com