Cotton thread supply frame for textile manufacturing machine

A technology of textile machinery and cotton thread, which is applied in the field of cotton thread supply racks for textile machinery, and can solve the problems of dust removal on the surface of cotton thread that cannot be spun

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

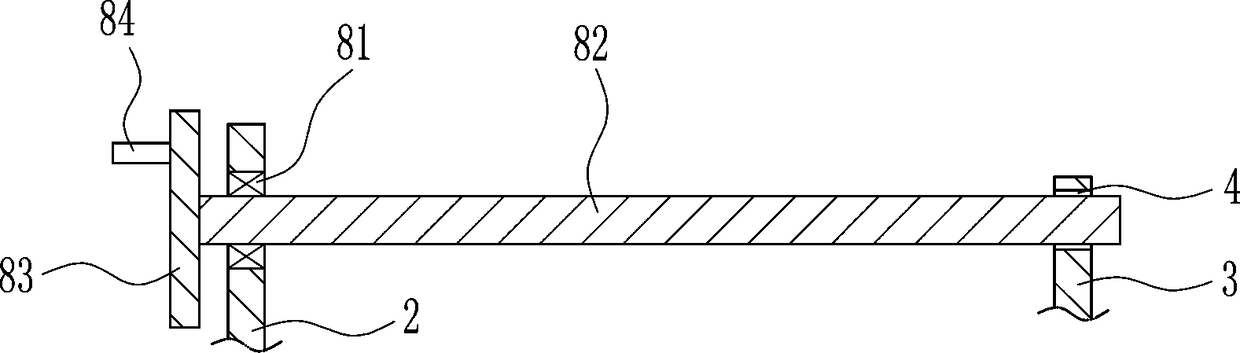

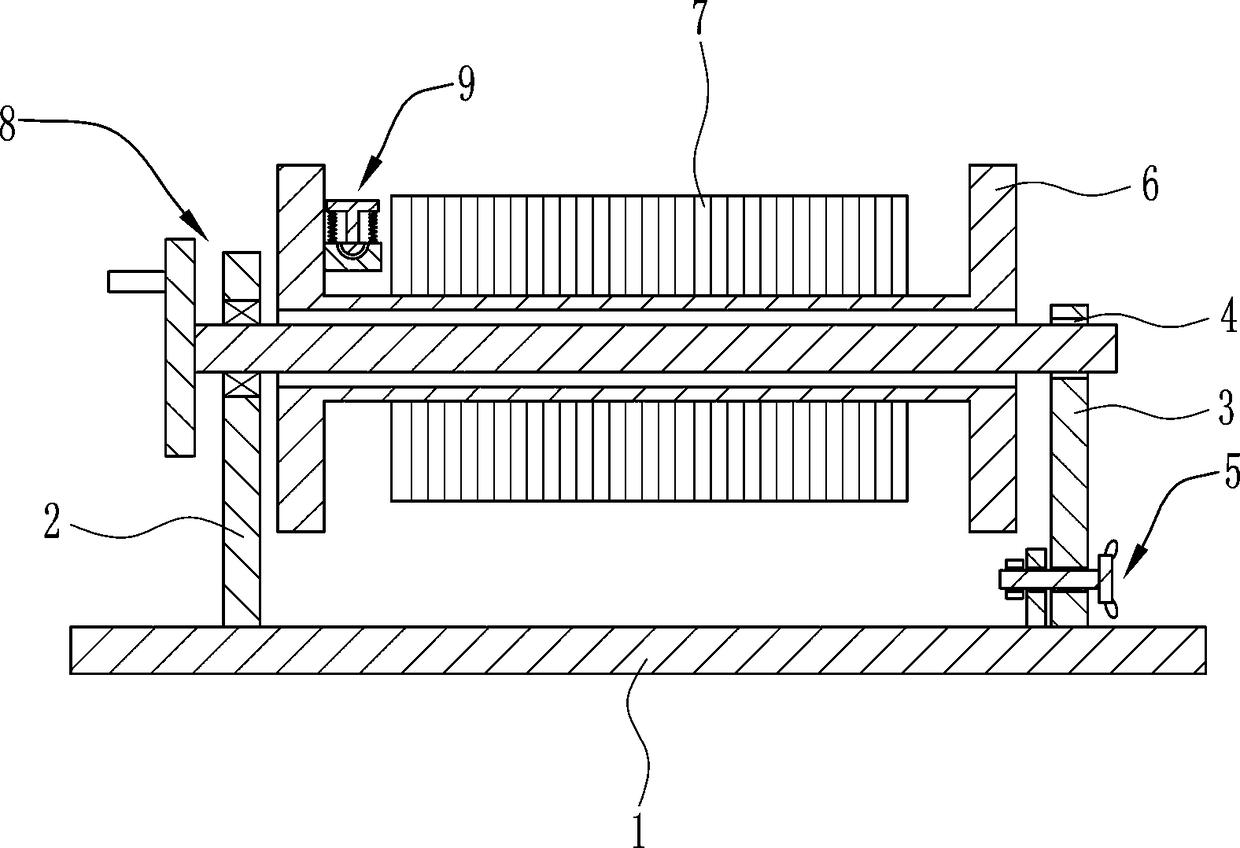

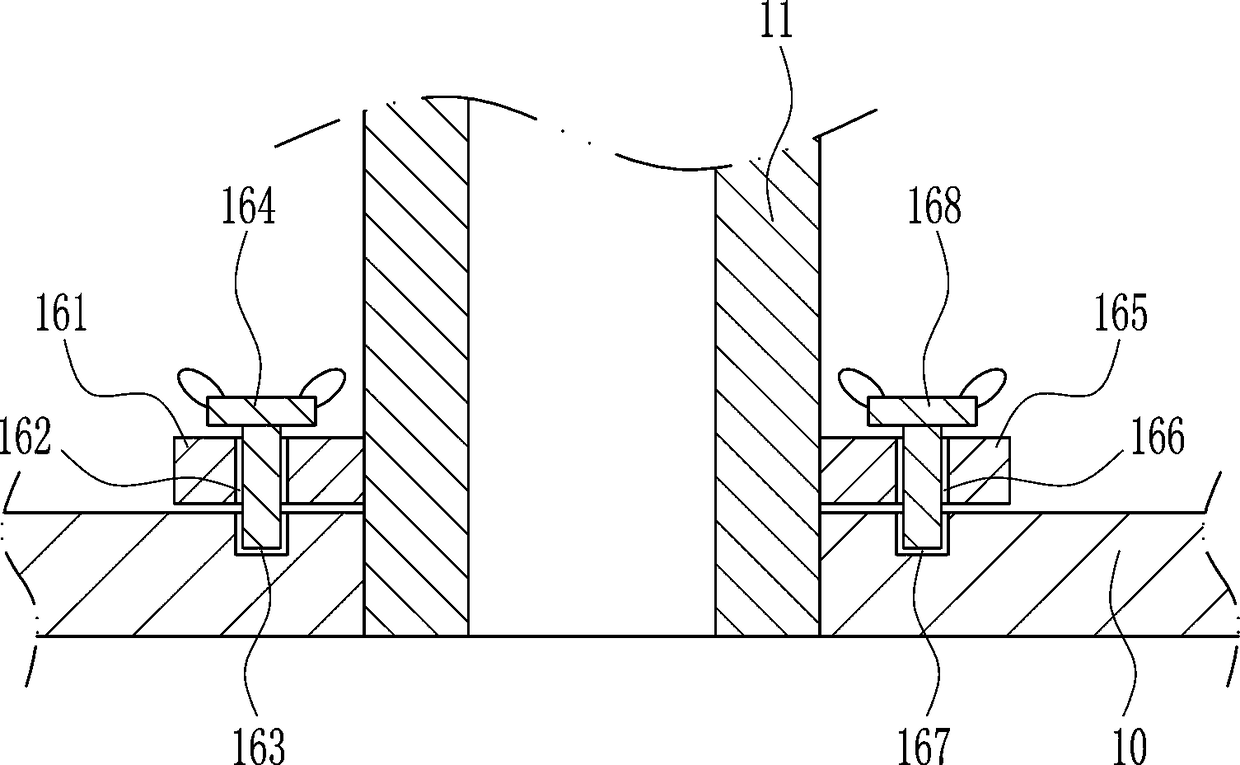

[0037] A cotton thread supply rack for textile machinery, such as Figure 1-8 As shown, it includes a mounting plate 1, a first supporting plate 2, a second supporting plate 3, a first fixing mechanism 5, a bobbin 6, a cotton thread body 7, a rotating mechanism 8, a locking mechanism 9, a mounting frame 10, a hollow Pipe 11, guide ring 12, scraping teeth 13, suction mechanism 15, second fixing mechanism 16 and collection mechanism 17; the first support plate 2 and the installation frame 10 are sequentially fixed on the top of the installation plate 1 along the length direction of the installation plate 1 ; The first fixing mechanism 5 is affixed to the top of the mounting plate 1, and is located behind the first supporting plate 2; the bottom of the second supporting plate 3 is affixed to the output end of the first fixing mechanism 5, and the second supporting plate 3 has a first pass hole 4; the rotating mechanism 8 is fixedly connected to the side of the first support plate...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap