Comprehensive solar photovoltaic power generation and salt preparation system

A solar photovoltaic and integrated system technology, applied in the field of solar photovoltaic power generation and salt-making comprehensive utilization system, can solve the problems of low solar energy utilization rate, inability to make salt, and low economic benefits, so as to improve power generation efficiency and photovoltaic power generation efficiency , Strengthen the effect of water evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

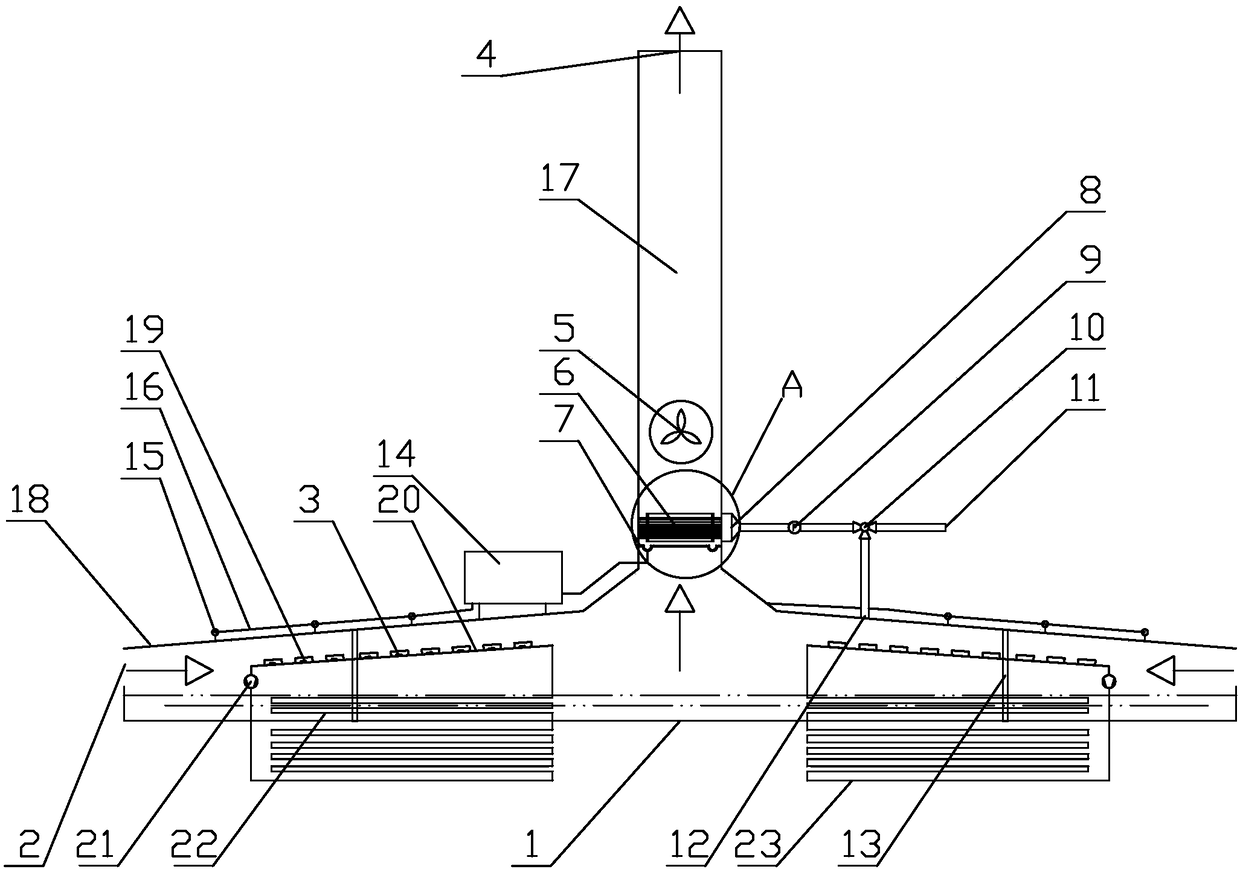

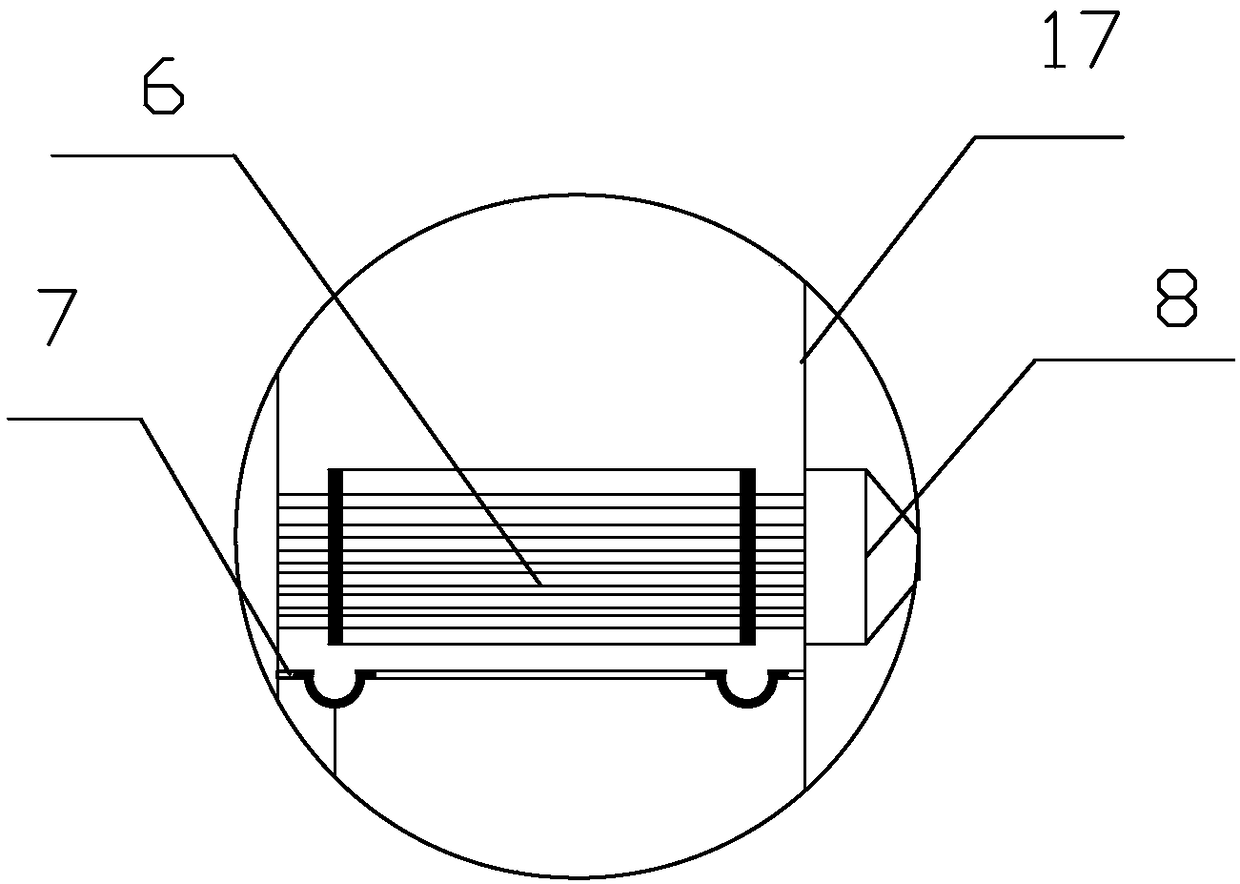

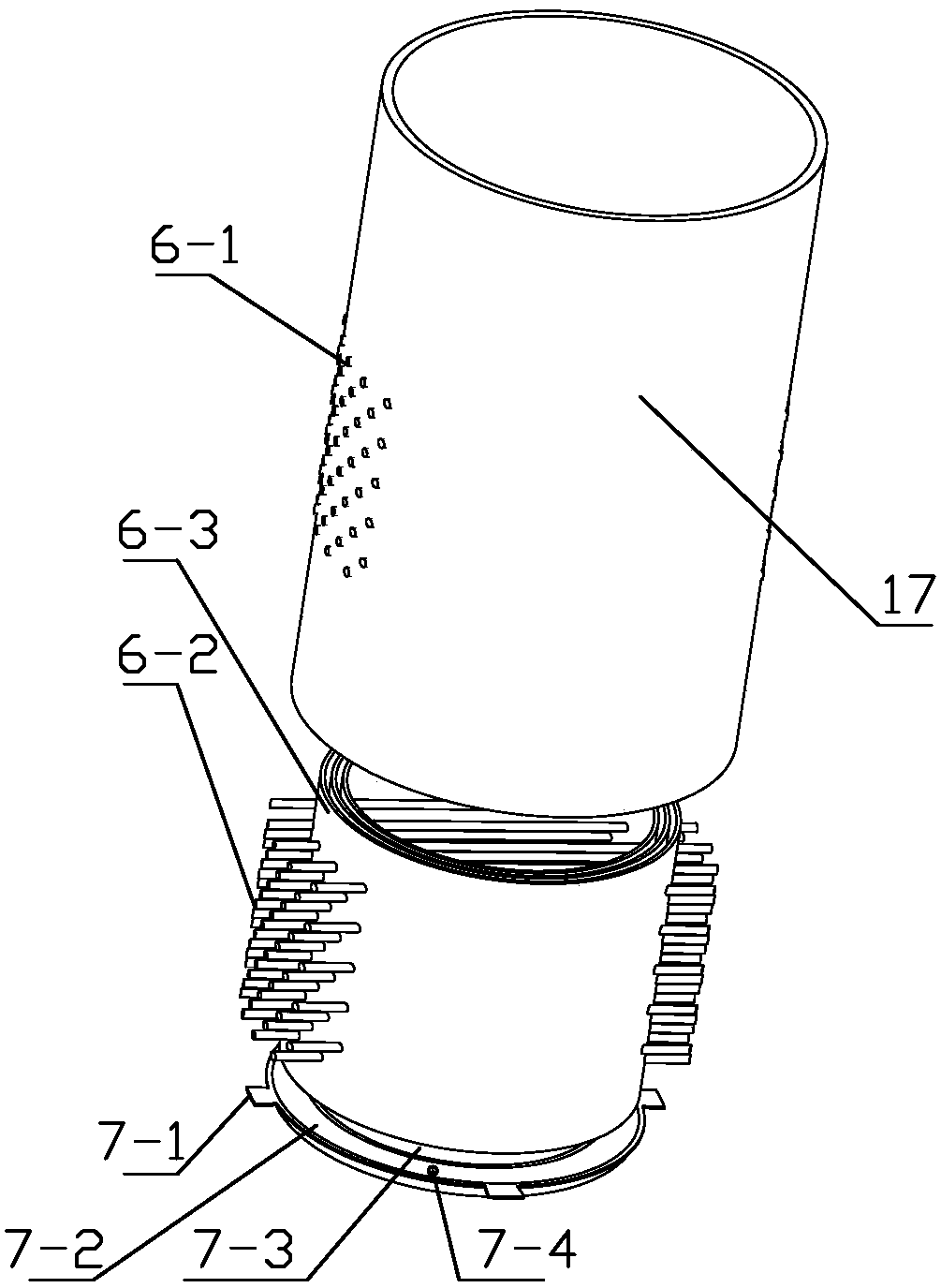

[0022] The schematic diagram of a kind of solar photovoltaic power generation and salt making comprehensive system of the present invention is as follows Figure 1-Figure 3 As shown, a chimney 17 and a transparent heat collection shed 18 are arranged on the salt field 1, and a condensing heat exchange device 6 is arranged on the chimney 17. A concentrated photovoltaic system is arranged below the transparent heat collection shed 18 . The concentrating photovoltaic system is composed of multiple concentrating photovoltaic modules 19, concentrating photovoltaic cells 3, battery cooling pipes 20 and supports 13, the back of the concentrating photovoltaic cells 3 is in close contact with the battery cooling pipes 20, The front side of the photovoltaic cell 3 is in contact with the air. The battery cooling pipe 20 is sequentially connected with the ground heat exchange pipe 22 , the underground heat exchange pipe 23 and the circulation pump 21 to form a closed cooling heat exchang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com