Solar photovoltaic chimney salt-making system

A solar photovoltaic and chimney technology is applied in the field of salt production, which can solve the problems of low utilization rate of solar energy, inability to produce salt, and low economic benefits, and achieve the effects of improving the productivity of salt production, increasing photovoltaic power generation, and improving utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

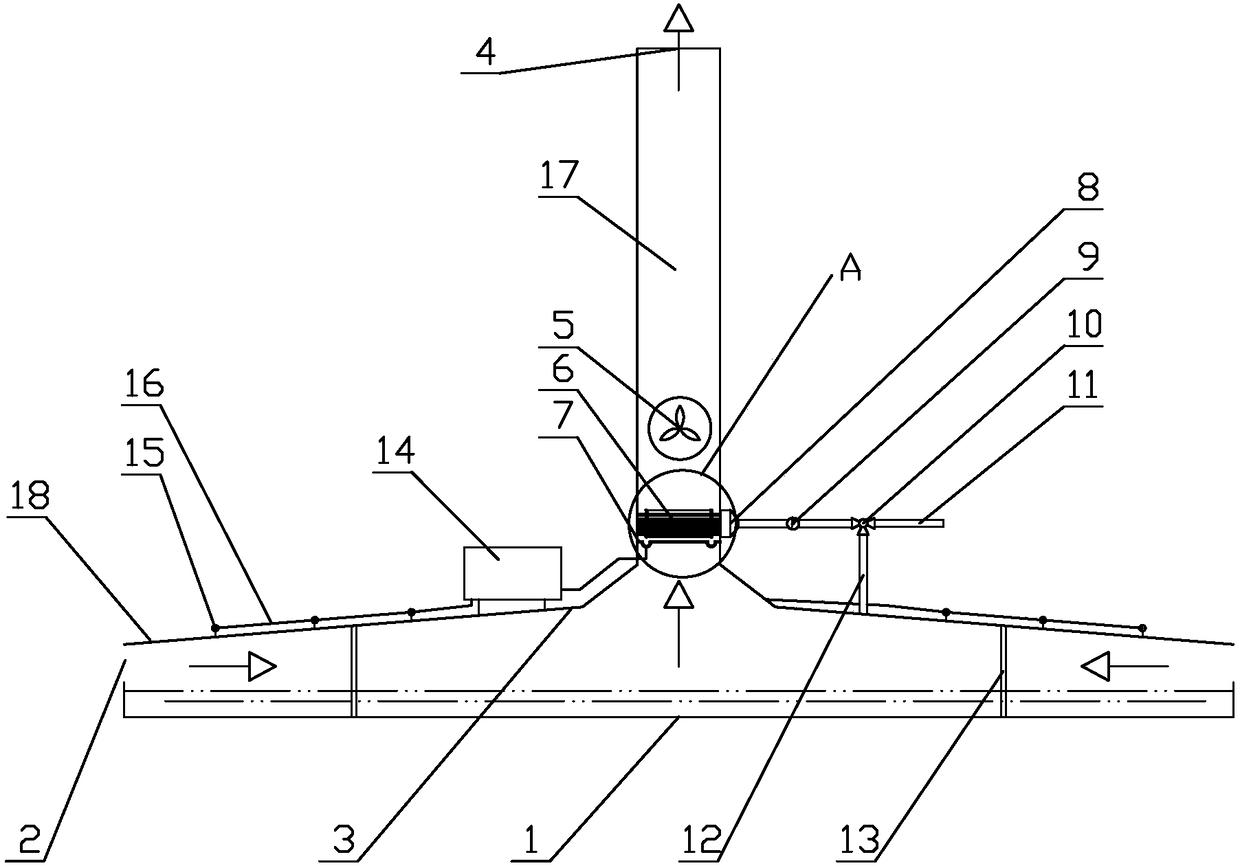

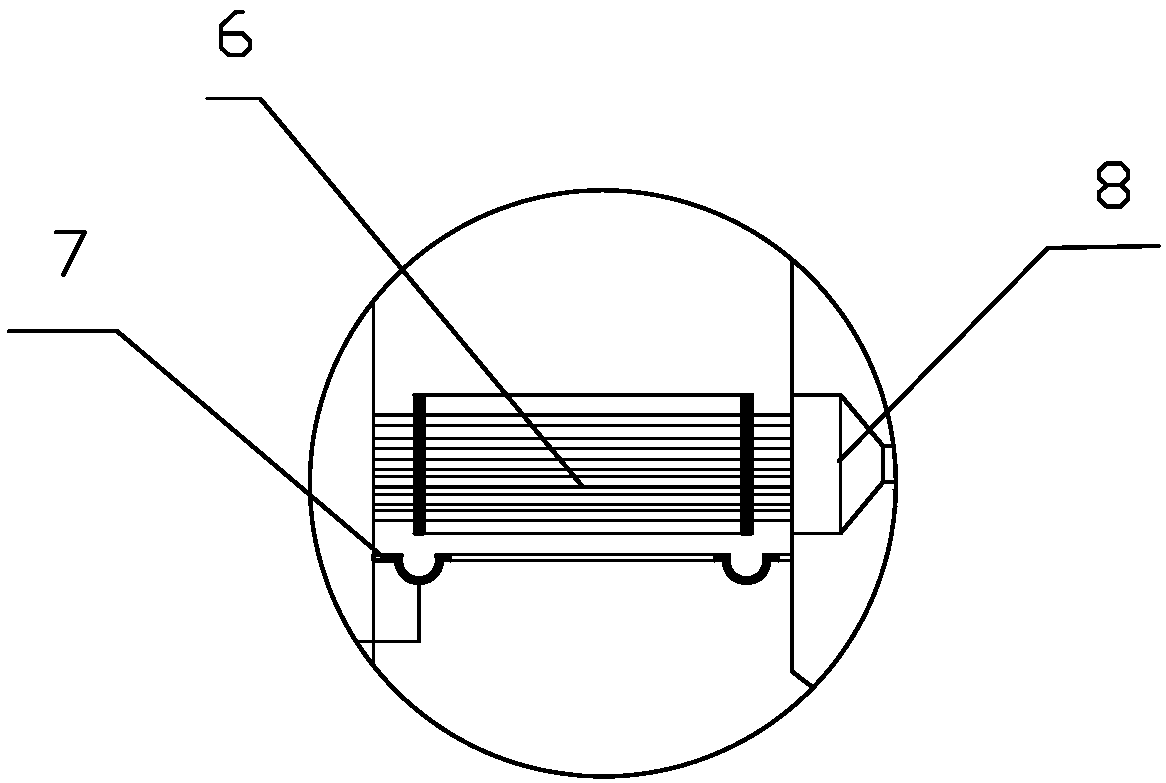

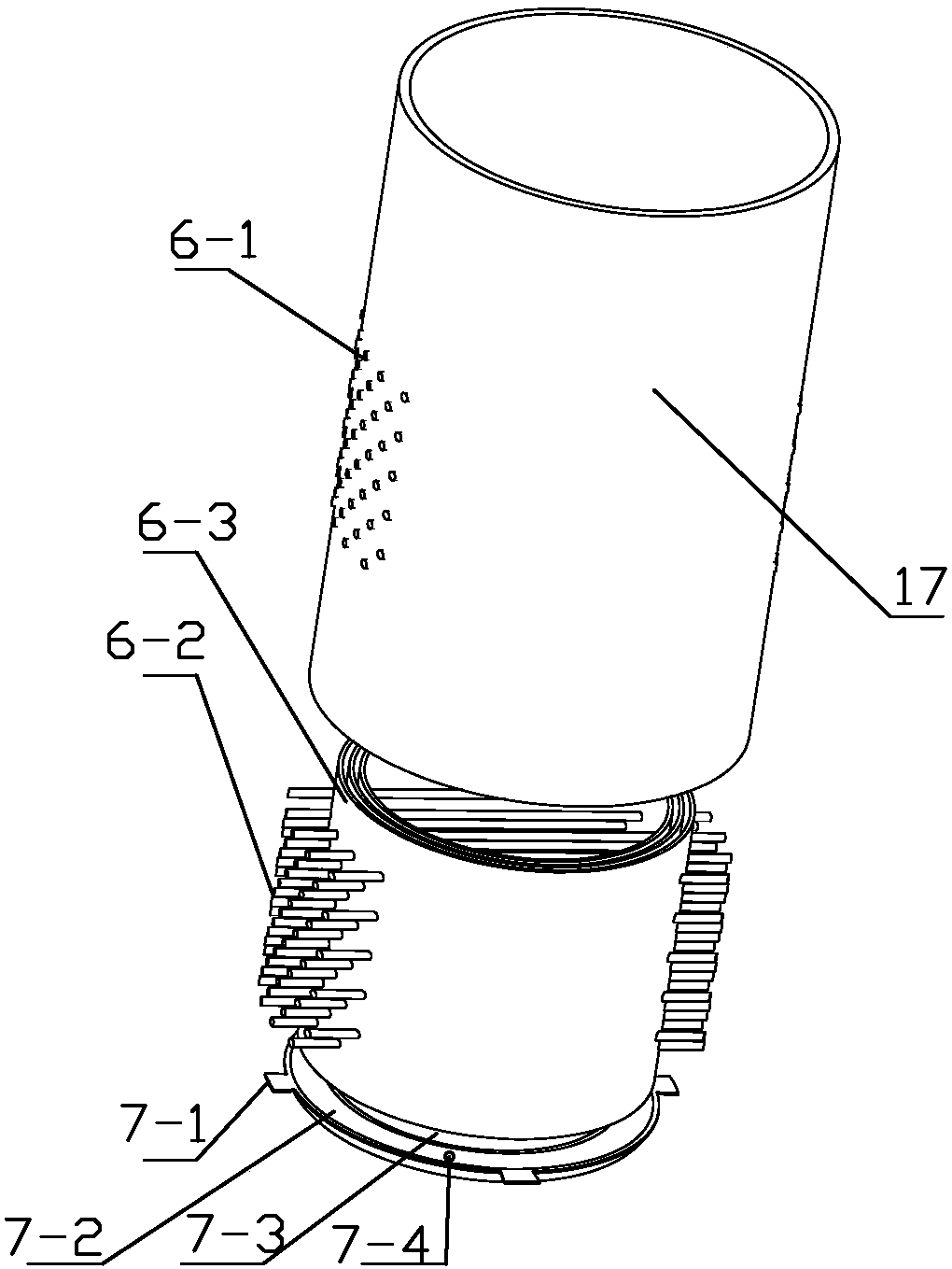

[0021] figure 1 Shown is a schematic structural diagram of a solar photovoltaic chimney salt production system of the present invention, and a chimney 17 and a photovoltaic heat collection shed 18 are arranged on the salt field 1 . A condensing heat exchange device 6 is installed on the chimney 17 . The condensation heat exchange device 6 is preferably installed between the upper part of the photovoltaic heat collection shed 18 and the chimney 17 . The photovoltaic heat collection shed 18 includes a roof 3 and a support 13 formed by closely connecting multiple photovoltaic modules, the support 13 supports the roof 3, and the edge of the roof 3 and the salt field 1 form a Heat collection shed entrance 2. In this embodiment, the edge of the roof is preferably inclined downward to form a slope roof, and the inclination angle of the roof 3 is ≤45°. One side of the condensing heat exchange device 6 is provided with an air guide port 8, and the air outlet of the air guide port 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com