Nitrogen-sulfur co-doped graphene quantum dot material, its preparation method and application

A graphene quantum dot, nitrogen-sulfur co-doping technology, applied in the fields of its preparation, graphene quantum dot materials, and fluorescent nanomaterials, can solve the problem that the two-photon fluorescence properties of graphene quantum dots are not significantly improved, and achieve the promotion of The effect of application development, two-photon fluorescence performance improvement, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

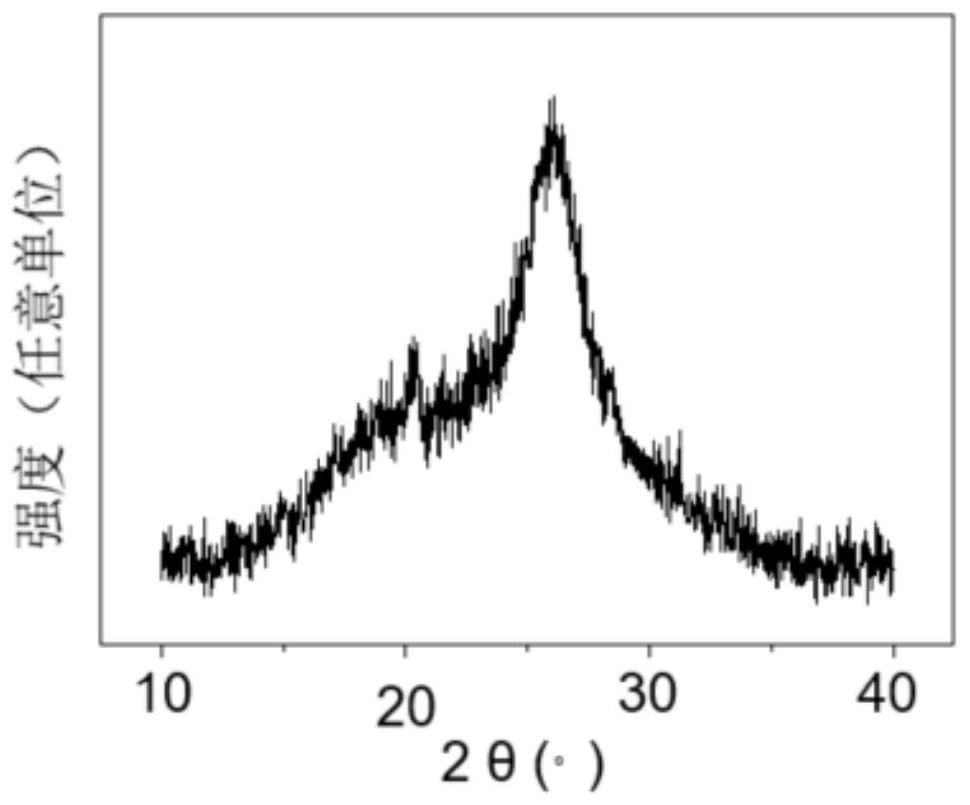

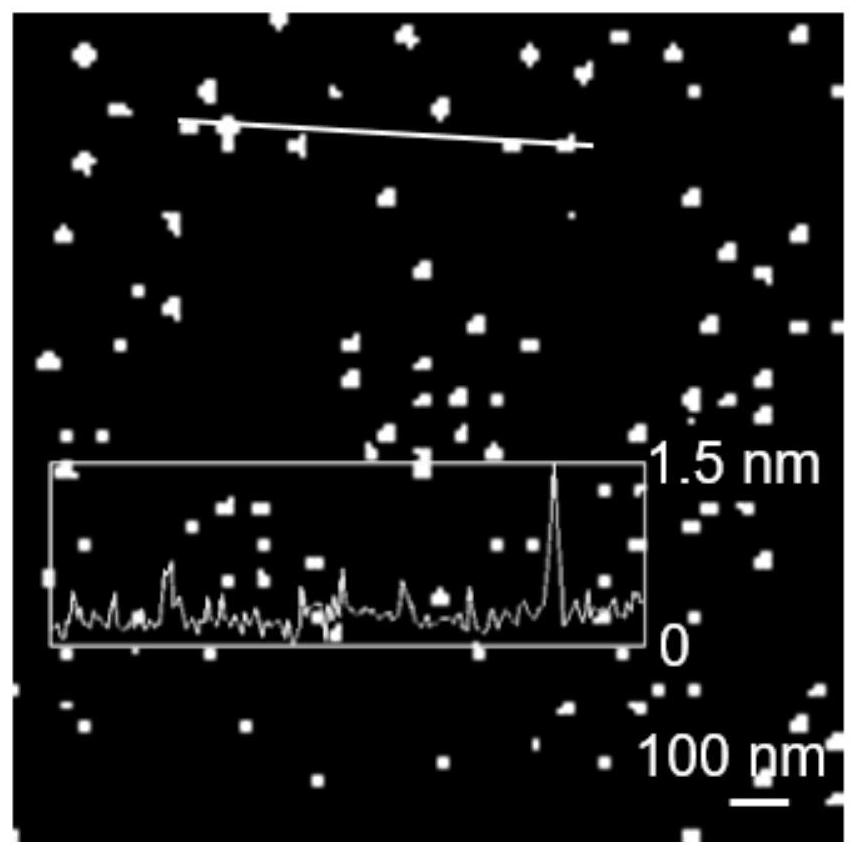

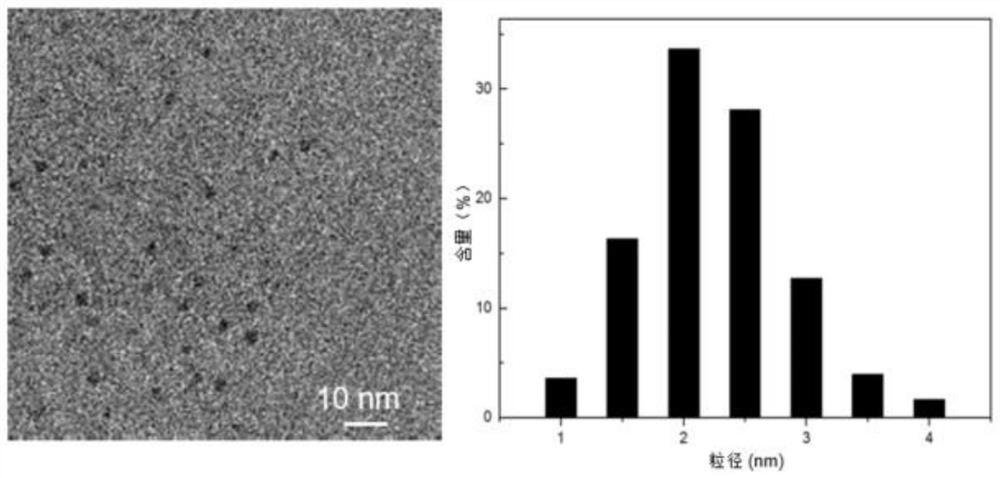

[0026] In this example, see Figure 1 to Figure 5 , a nitrogen-sulfur co-doped graphene quantum dot material, the nitrogen-sulfur co-doped graphene quantum dots comprise nano-scale graphene nanosheets connected to hydroxyl, amino or sulfonic acid groups on edge carbon atoms layer; the average diameter of the nitrogen-sulfur co-doped graphene quantum dot is 3.0nm, and the average thickness is 1.35nm, and the nitrogen-sulfur co-doped graphene quantum dot contains C, N, O, S, H5 One element, nitrogen-sulfur co-doped graphene quantum dots consist of at least one layer of graphene nanosheets.

[0027] A kind of present embodiment is based on the preparation method of nitrogen-sulfur co-doped graphene quantum dot material, adopts molecular fusion method, comprises the steps:

[0028] a. With 1,3,6-trinitropyrene as a precursor, 0.05 g of 1,3,6-trinitropyrene was uniformly dispersed in 20 mL of water under ultrasonic conditions, and ultrasonic treatment was performed for 10 minutes ...

Embodiment 2

[0034] This embodiment is basically the same as Embodiment 1, especially in that:

[0035] In this embodiment, a method for preparing a nitrogen-sulfur co-doped graphene quantum dot material in this embodiment uses a molecular fusion method, including the following steps:

[0036] a. With 1,3,6-trinitropyrene as a precursor, 0.3g of 1,3,6-trinitropyrene was uniformly dispersed in 10mL of water under ultrasonic conditions, and ultrasonic treatment was performed for 10 minutes to prepare The concentration of 1,3,6-trinitropyrene was 30 mg / mL 1,3,6-trinitropyrene dispersion, and then 0.1 g of sub- Ammonium sulfate, continue to ultrasonically disperse the mixed solution for 10 minutes to obtain a reactant system solution fully mixed with 1,3,6-trinitropyrene and ammonium sulfite, and then transfer the reactant system solution to a polytetrafluoroethylene solution with a volume of 50mL In an ethylene high-pressure reactor, conduct a hydrothermal reaction at a temperature of 150°C ...

Embodiment 3

[0040] This embodiment is basically the same as the previous embodiment, and the special features are:

[0041] In this embodiment, a method for preparing a nitrogen-sulfur co-doped graphene quantum dot material in this embodiment uses a molecular fusion method, including the following steps:

[0042] a. With 1,3,6-trinitropyrene as a precursor, 1.0 g of 1,3,6-trinitropyrene was uniformly dispersed in 10 mL of water under ultrasonic conditions, and ultrasonic treatment was performed for 50 minutes to prepare 1,3,6-Trinitropyrene dispersion with 100mg / mL concentration of 1,3,6-Trinitropyrene, then add 5g of sulfurous acid to the 1,3,6-Trinitropyrene dispersion Ammonium, continue to ultrasonically disperse the mixed solution for 10 minutes to obtain a reactant system solution fully mixed with 1,3,6-trinitropyrene and ammonium sulfite, and then transfer the reactant system solution to a polytetrafluoroethylene solution with a volume of 50mL In a high-pressure reactor, carry out ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com