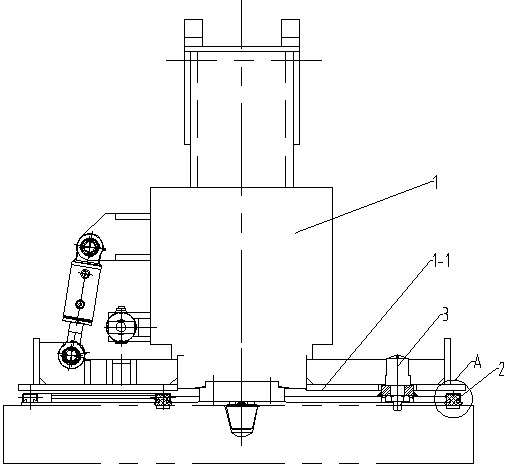

Segment grabbing-lifting detecting device for vacuum suction cup

A vacuum suction cup and detection device technology, which is applied in the direction of measuring devices, optical devices, shaft equipment, etc., can solve the problems of easy deformation of components and low snatch efficiency, and achieve the effects of improving snatch efficiency, preventing pressure release, and improving snatch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

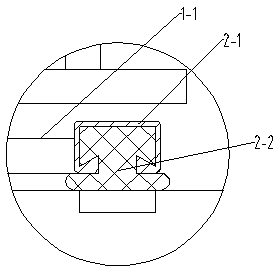

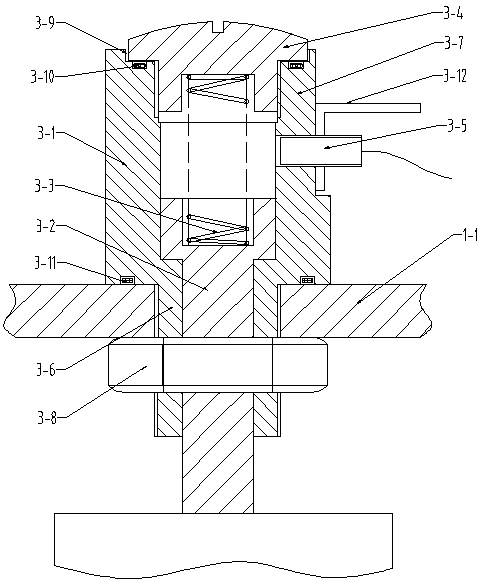

[0018] Embodiment 2, a snatch detection device for a segment vacuum suction cup, the suction cup partition 1-1 is provided at the lower part of the suction cup mechanism 1, the installation sleeve 3-1 is a stepped sleeve, and the lower step of the stepped sleeve The outer cylinder wall of the cylinder 3-6 is provided with external thread, and the lower-step cylinder 3-6 passes through the suction cup partition 1-1 and is fixedly connected with the suction cup partition 1-1 through the mounting nut 3-8, which is convenient for assembly and disassembly, and the step The inner wall of the upper step tube 3-7 of the sleeve is provided with an internal thread, and the internal thread is engaged with the external thread on the nut 3-4, and is used for fixing the spring through the fixed connection between the nut and the upper step tube. The top of the upper step tube 3-7 is provided with a positioning groove 3-9, the nut 3-4 corresponds to the positioning groove 3-9, and the positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com