Asphalt mixture grading design method based on grading interlocking and voids in mineral aggregate

A gap rate and gradation technology, applied in design optimization/simulation, calculation, special data processing applications, etc., can solve problems such as lack of understanding of mechanical properties and structural stability, road life and road performance can not meet the use requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A gradation design method of asphalt mixture based on gradation embedding and mineral material gap ratio, comprising the following steps:

[0021] 1) Collect the gradation data of the local mixture design in the past, and solve the parameters in the prediction model of the mineral material gap ratio according to the embedding theory planning;

[0022] The prediction model of mineral material void ratio obtained from the theory of embedding is adopted:

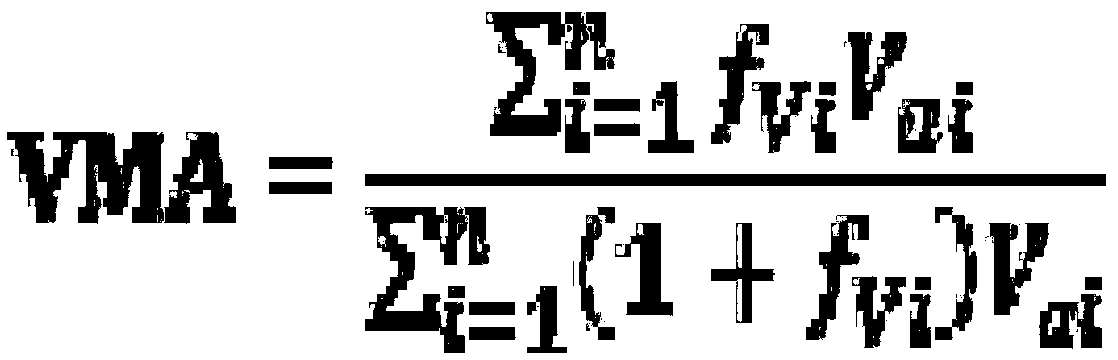

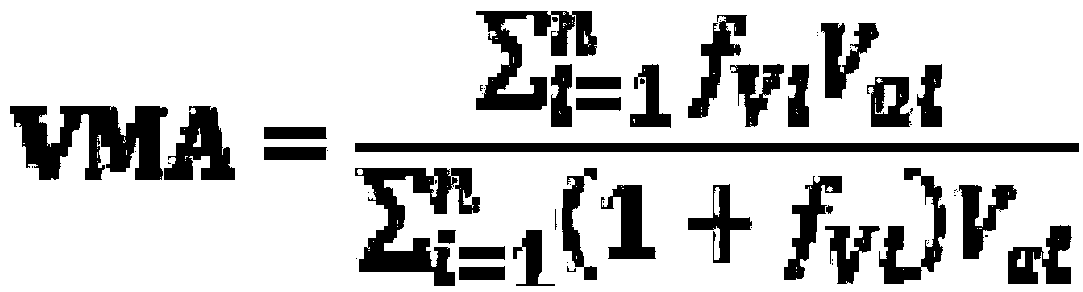

[0023]

[0024] In the formula: VMA is the predicted value of mineral material gap ratio; f vi is the impact factor of mineral material void ratio; V ai is the sieve volume of the i-th file aggregate;

[0025] f vi =[V vi -V v(i-1) ] / V ai

[0026] Where: V vi is the volume of the pores after the i-th file aggregate is mixed; V v(i-1) is the volume of the pores after the i-1th grade aggregate is mixed; V ai is the sieve volume of the i-th file aggregate;

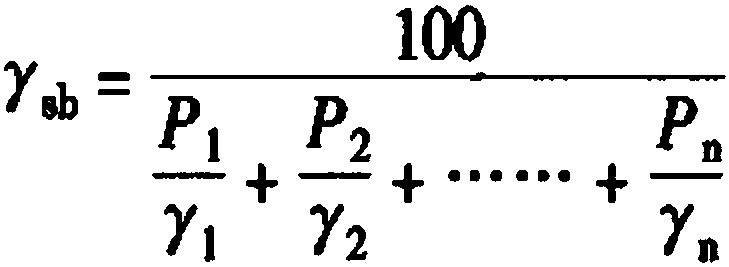

[0027] 2) Detect the physics of aggregates at variou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com