Live working T-type working wire clip of 10kV power distribution line

A technology for live work and power distribution lines, applied in circuits, electrical components, conductive connections, etc., can solve the problems that the current carrying capacity cannot meet the requirements of the grid, it is not easy to take off, and the wire clips are loosened, so as to facilitate machine-assisted operations and The effect of robot operation, simple operation and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 (when the artificial insulating rod method is used)

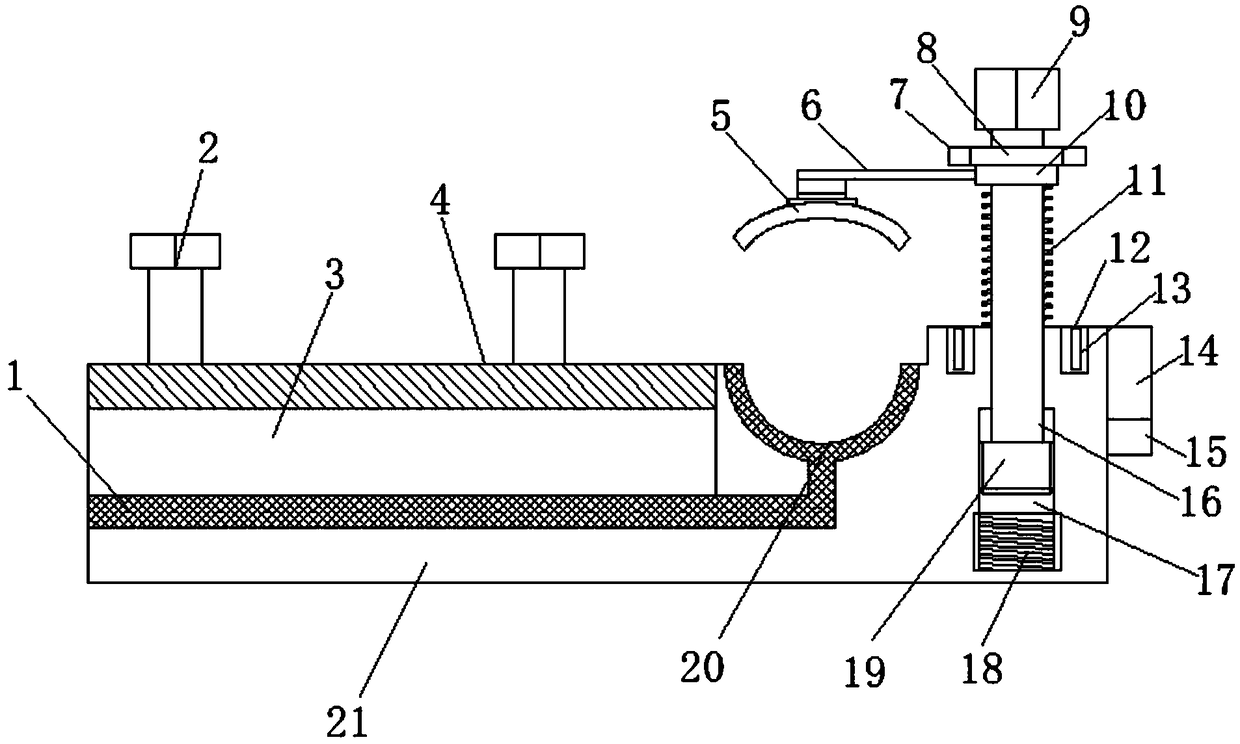

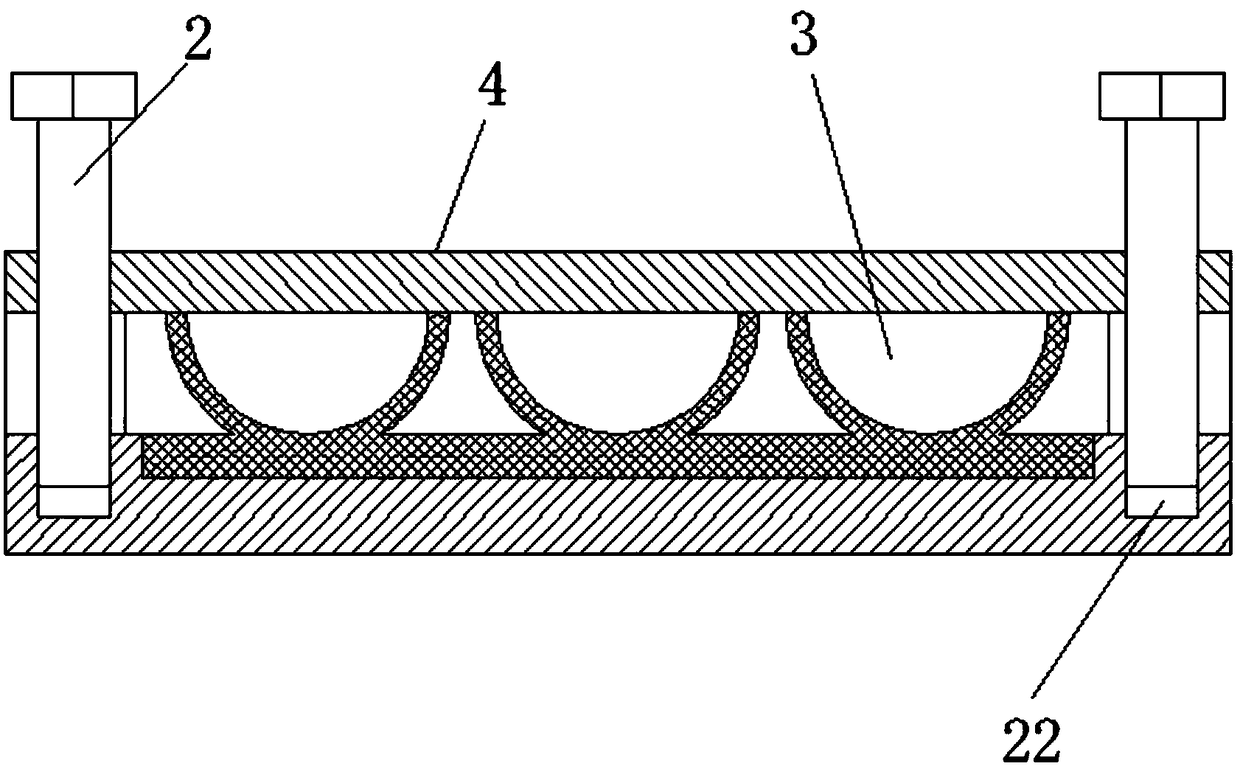

[0025] A T-shaped work clamp for live work on a 10kV distribution line, comprising an insulating seat 21, one end of the insulating seat 21 is provided with a limiting hole 17, a sliding column 16 is arranged in the limiting hole 17, and a limiting thread is provided at the lower end of the sliding column 16 The column 19, the lower end of the limit hole 17 is provided with an internal thread 18, the upper end of the sliding column 16 is provided with a collar 10, the collar 10 is connected to the clip 5 through the connecting frame 6, and the position of the corresponding insulating seat 21 below the clip 5 is provided with a main line slot, the main line The main wire groove conductive seat 20 is arranged in the groove, the limit spring 11 is arranged between the collar 10 and the insulating seat 21, the upper end of the collar 10 is provided with a cover plate 8, and the outside of the cover plate 8 is...

Embodiment 2

[0027] Example 2 (during robot operation)

[0028] A T-shaped work clamp for live work on a 10kV distribution line, comprising an insulating seat 21, one end of the insulating seat 21 is provided with a limiting hole 17, a sliding column 16 is arranged in the limiting hole 17, and a limiting thread is provided at the lower end of the sliding column 16 The column 19, the lower end of the limit hole 17 is provided with an internal thread 18, the upper end of the sliding column 16 is provided with a collar 10, the collar 10 is connected to the clip 5 through the connecting frame 6, and the position of the corresponding insulating seat 21 below the clip 5 is provided with a main line slot, the main line The main wire groove conductive seat 20 is arranged in the groove, the limit spring 11 is arranged between the collar 10 and the insulating seat 21, the upper end of the collar 10 is provided with a cover plate 8, and the outside of the cover plate 8 is provided with a ring magnet 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com