A stepper motor with easy drainage

A stepper motor and housing technology, applied in the field of electric motors, can solve the problems of increased failure rate, reduced sealing performance, unfavorable air conditioning repair and maintenance, etc., to improve the ability to resist foreign objects, reduce the probability of occurrence, and reduce water ingress effect of risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

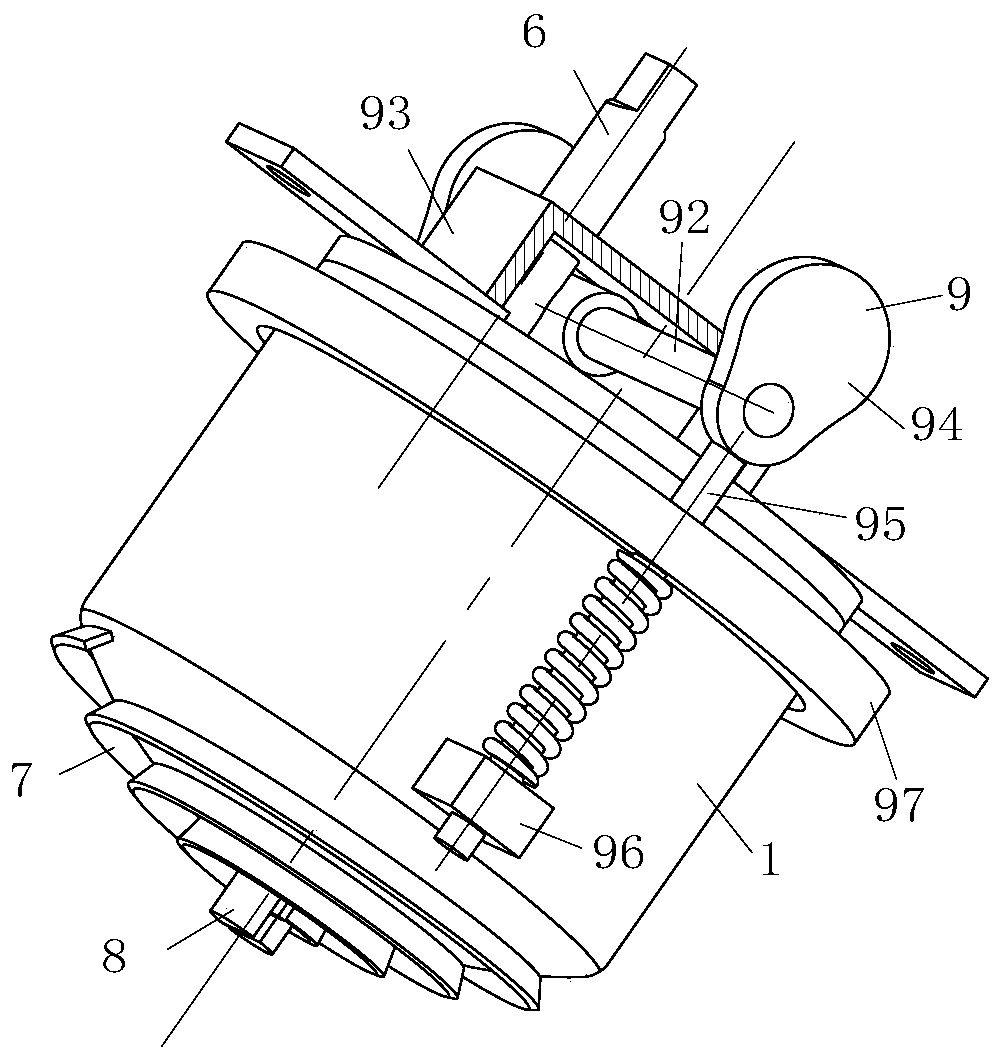

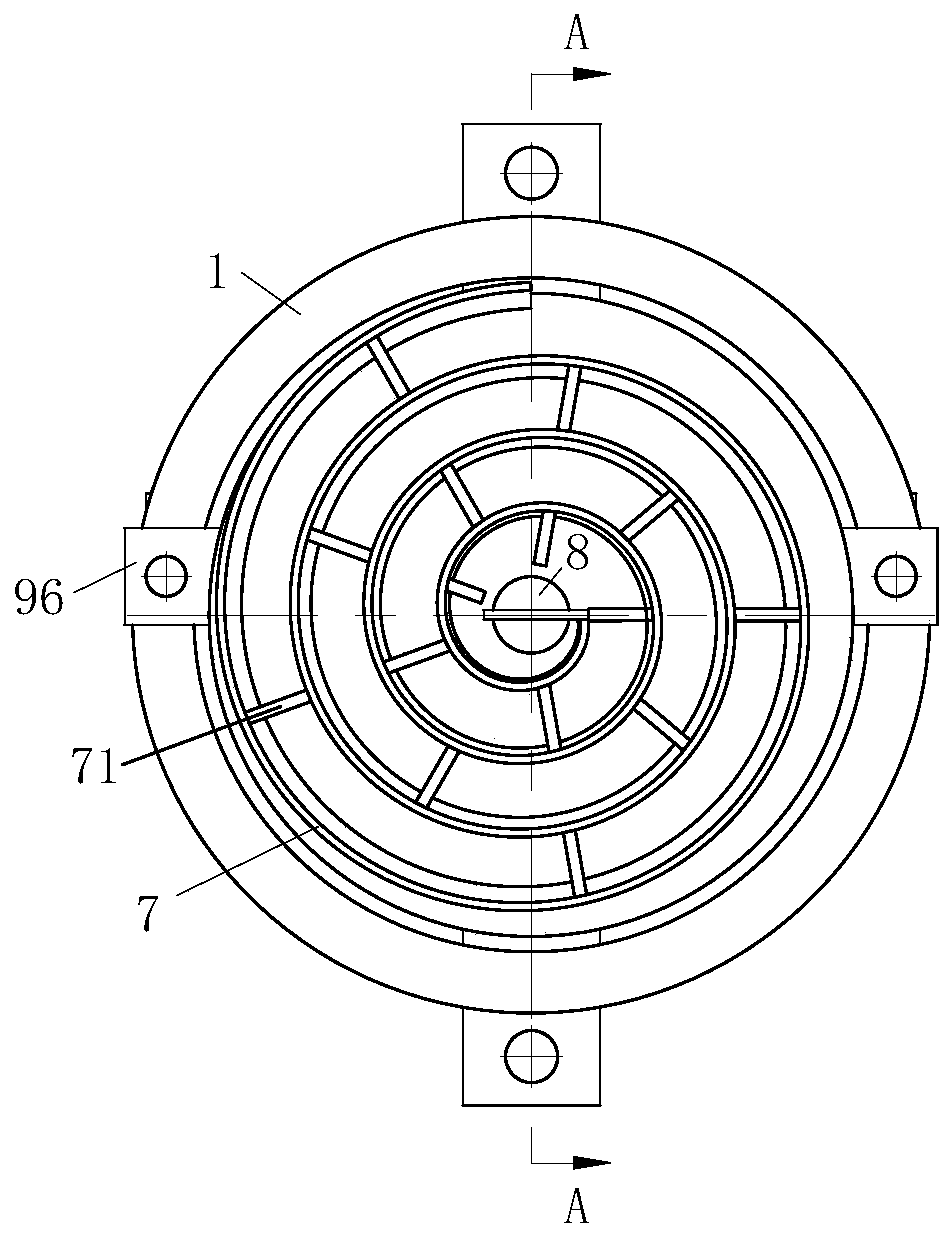

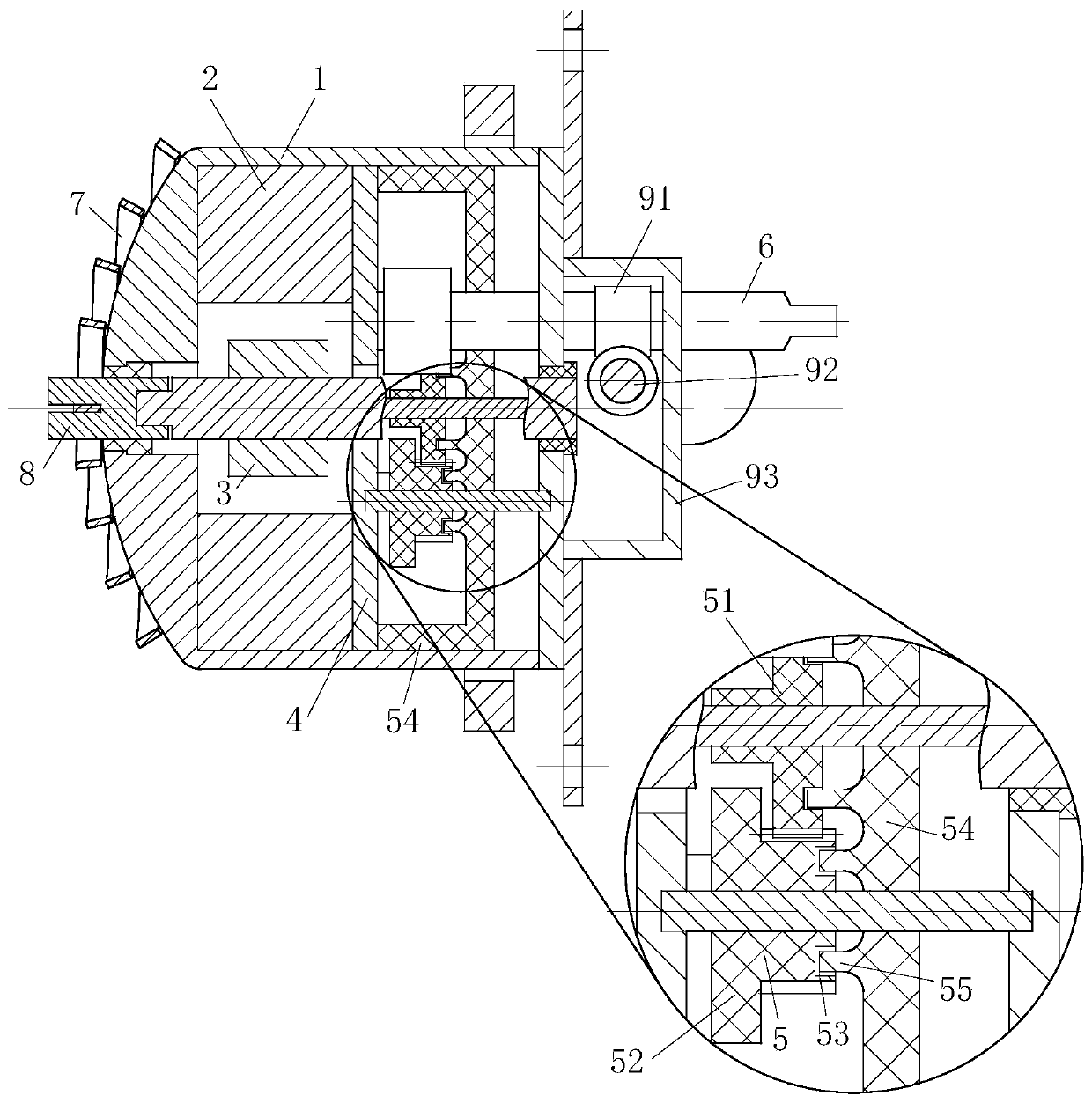

[0030] As an embodiment of the present invention, the spiral plate 7 is provided with a set of alternately arranged vertical plates 71. When the spiral plate 7 rotates and wipes the water, it generates airflow, accelerates the evaporation of water, takes away the heat of the motor, and improves the service life of the motor. .

[0031] As an embodiment of the present invention, one end of the rotor 3 is provided with a ring of shrapnel 31, and the shrapnel 31 is arranged along the tangential direction of the outer circle of the rotor 3; One side of the slot 81 is perpendicular to the outer circle of the rotor 3; the other side of the stepped slot 81 is inclined to the outer circle of the rotor 3, and the tangent angle to the rotor is set at 20-30°, and the air-conditioning air deflector swings cyclically, that is, the stepping motor needs Frequent positive and negative rotation, by setting the shrapnel 31 and the step groove 81 to keep the spiral plate 7 rotating in one direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com