Dedusting apparatus for rice milling

A technology for dust removal equipment and rice processing, which is applied to the separation of solids from solids by air flow, solid separation, chemical instruments and methods, etc., can solve problems such as inability to completely clean up, achieve strong dust removal effect, ensure taste, and reduce dust The effect of the content of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

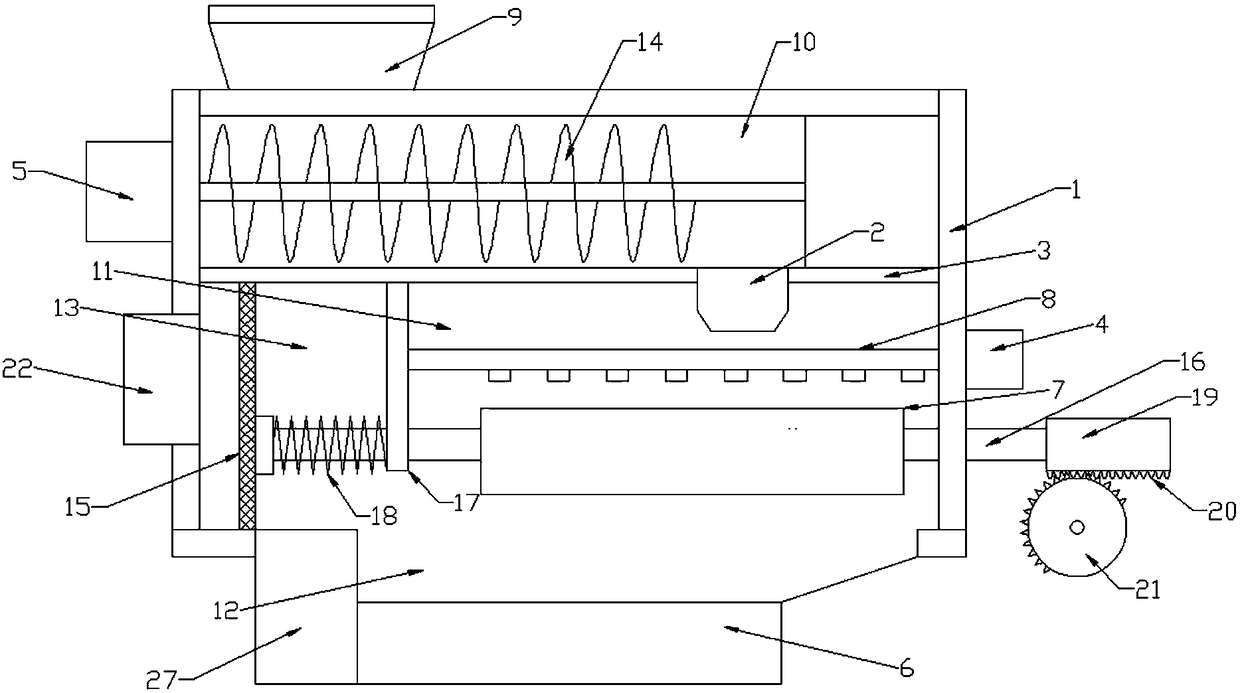

[0020] Please refer to the figure, in an embodiment of the present invention, a kind of dust removal equipment for rice processing includes a box body 1, a lower hopper 2, a partition 3, a blower fan 4, a motor 5 and a collection box 6; The dividing plate 3 of cylindrical structure, the dividing plate 3 is provided with conveying cavity 10, is connected with the feeding hopper 9 that is positioned at the left end at the top of conveying cavity 10, sends rice inwardly by feeding hopper 9, in the feeding hopper 9 A sealing cover is also covered on the top to keep the internal seal; a horizontal motor 5 is fixed on the outer wall of the box body 1 corresponding to the left end of the delivery chamber 10, and the output shaft of the motor 5 extends into the delivery chamber 10 and is located at the side of the delivery chamber 10. On the horizontal central axis, a horizontal spiral blade 14 is fixedly connected to the output shaft of the motor 5, and the motor 5 drives the spiral b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com