A bamboo shoot longitudinal slicer

A slicer and vertical technology, which is applied in metal processing and other directions, can solve the problems that the bamboo shoots cannot be opened into a whole piece, and it is difficult to meet the needs of use, so as to achieve the effect of smooth slice process, reduce labor cost, and facilitate processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

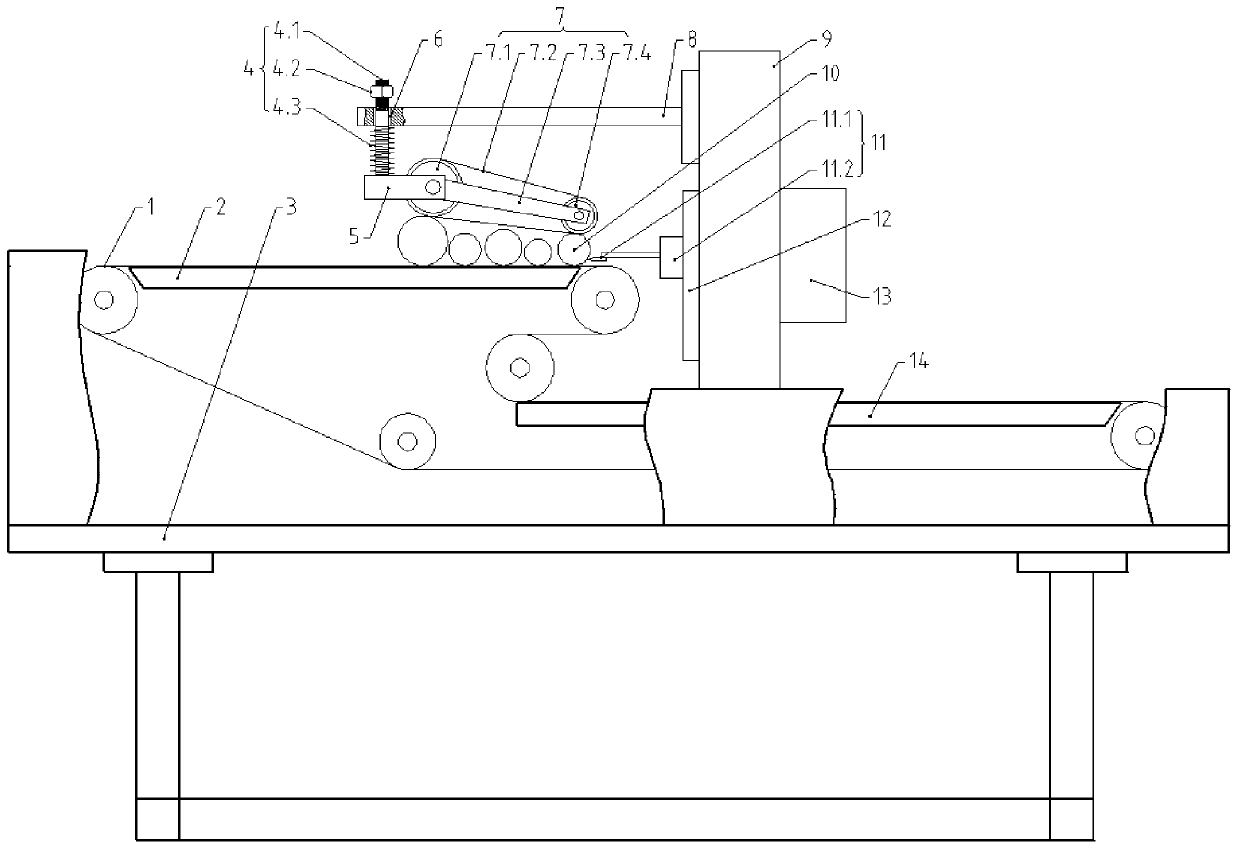

[0023] A bamboo shoot longitudinal slicer, comprising a frame 3, an operation console with a conveyor belt 1 is arranged on the frame 3, the operation console is divided into a left feeding part 2 and a right discharging part 14, and the There is a support beam 9, and the support beam 9 is provided with a drum-type auxiliary film opening mechanism 7 above the feeding part 2. There is a height difference between the drum-type auxiliary film opening mechanism 7 and the feeding part 2, and the supporting beam 9 is in the feeding part. 2 and the drum type auxiliary opening mechanism 7 are provided with a blade mechanism 11 for providing otch along the bamboo shoot length direction.

[0024] Working principle: The bamboo shoots 10 to be processed enter from the left side of the device under the action of the conveyor belt 1 to the right below the drum-type auxiliary film opening mechanism 7, the transmission direction of the drum-type auxiliary film opening mechanism 7 is opposite t...

Embodiment 2

[0027] This embodiment improves on the basis of Embodiment 1:

[0028] The support beam 9 is horizontally provided with a support plate 8 with a through hole 6 at the end, and a connection mechanism 4 is provided at the through hole 6 on the support plate 8, and the connection mechanism 4 includes a connecting rod b4 vertically arranged in the through hole 6. 1. The outer wall of the top end of the connecting rod b4.1 is provided with an adjusting nut 4.2 connected by thread, and the connecting rod b4.1 is provided with an elastic sleeve between the bottom end and the lower surface of the support plate 8, and the end of the connecting rod b4.1 is connected with a Connecting rod a5, one side of the drum type auxiliary opening mechanism 7 is hinged with connecting rod a5.

[0029] The advantages of the above improvements are: the spring in the connecting mechanism enables the connecting rod b and the drum-type auxiliary film opening mechanism to be adjusted up and down according...

Embodiment 3

[0031] This embodiment is improved on the basis of the above embodiments:

[0032] The drum-type auxiliary opening mechanism 7 includes a support frame 7.3, and the two ends of the support frame 7.3 are respectively provided with a driving drum 7.1 and a driven drum 7.4, and a belt 7.2 is set on the driving drum 7.1 and the driven drum 7.4, and one end of the support frame 7.3 is connected a5 hinged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com