Truck with cover tyres provided with deformation holes

A technology of deforming holes and trucks, applied in the direction of wheels, tire measurement, vehicle parts, etc., can solve the problems of inconvenience, low edge strength of the outer ring, poor heat dissipation effect of the wheels, etc., and achieve high edge strength, good heat dissipation effect, and good cooling effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

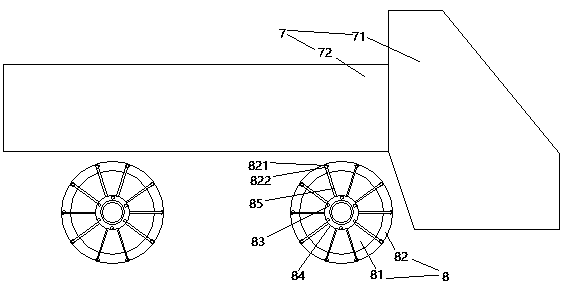

[0021] Embodiment one, see figure 1 , a truck with deformation holes in the outer tire, including a car body 7 and wheels 8 supporting the car body. The vehicle body 7 includes a driver's cabin 71 and a vehicle body 72 . Wheel 8 comprises steel wheel 81 and cover tire 82. The tire cover 82 is provided with several deformed through holes 821 distributed axially along the circumferential direction of the cover tire. A rigid inner core 822 passes through the deformation through hole 821 . Steel wheel 81 is connected with connecting ring 84 by bolt 83 . The inner core 822 is connected with the connecting ring 84 through the connecting strip 85 .

[0022] During use, when anti-slip needs to be carried out, take off the bolt 83, then pull the connecting ring 84, the connecting ring will pull the inner core from the deformation through hole 821 on the cover tire through the connection bar, so that the position of the cover tire corresponding to the deformation through hole is in ...

Embodiment 2

[0023] Embodiment two, the difference with embodiment one is:

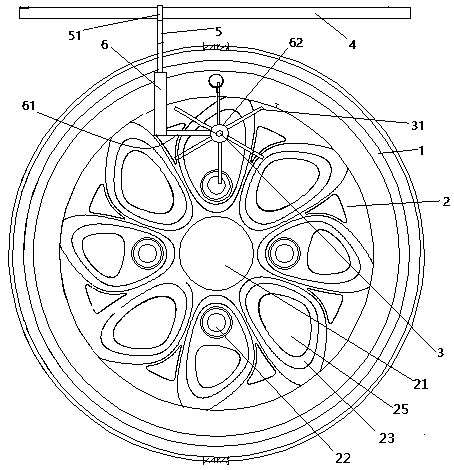

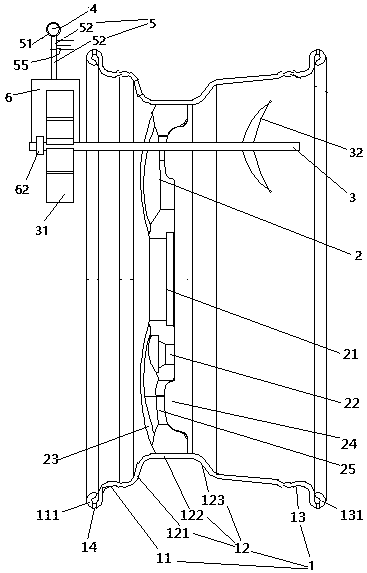

[0024] see figure 2 and image 3 , The steel wheel includes an outer ring 1, an inner plate 2, a guide rod 4 and a first connecting rod 5.

[0025] The inner plate 2 is circular. The inner plate 2 is provided with a wheel shaft through hole 21 and four mounting holes 22 uniformly distributed along the circumference of the wheel shaft through hole 1 . The outer side of the inner plate 2 is provided with eight protrusions 23 uniformly distributed along the circumference of the axle through hole 21 . The inner side of the inner panel 2 is provided with recesses 24 which are the same in number as the protrusions and correspond to the protrusions one by one. The bottom of the depression 24 is provided with a weight-reducing through hole 25 that communicates with the protrusion.

[0026] The outer ring 1 is rolled from an aluminum plate. The outer ring 1 includes an outer ring 11 provided with an outer outer bead...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com