Modular steel structure house and construction method thereof

A construction method and steel structure technology, applied in the direction of building structure, construction, etc., can solve the problems of long roof beams, inability to splice roof beams, inconvenient transportation, etc., to increase resistance, reduce construction period, and reduce transportation the effect of pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

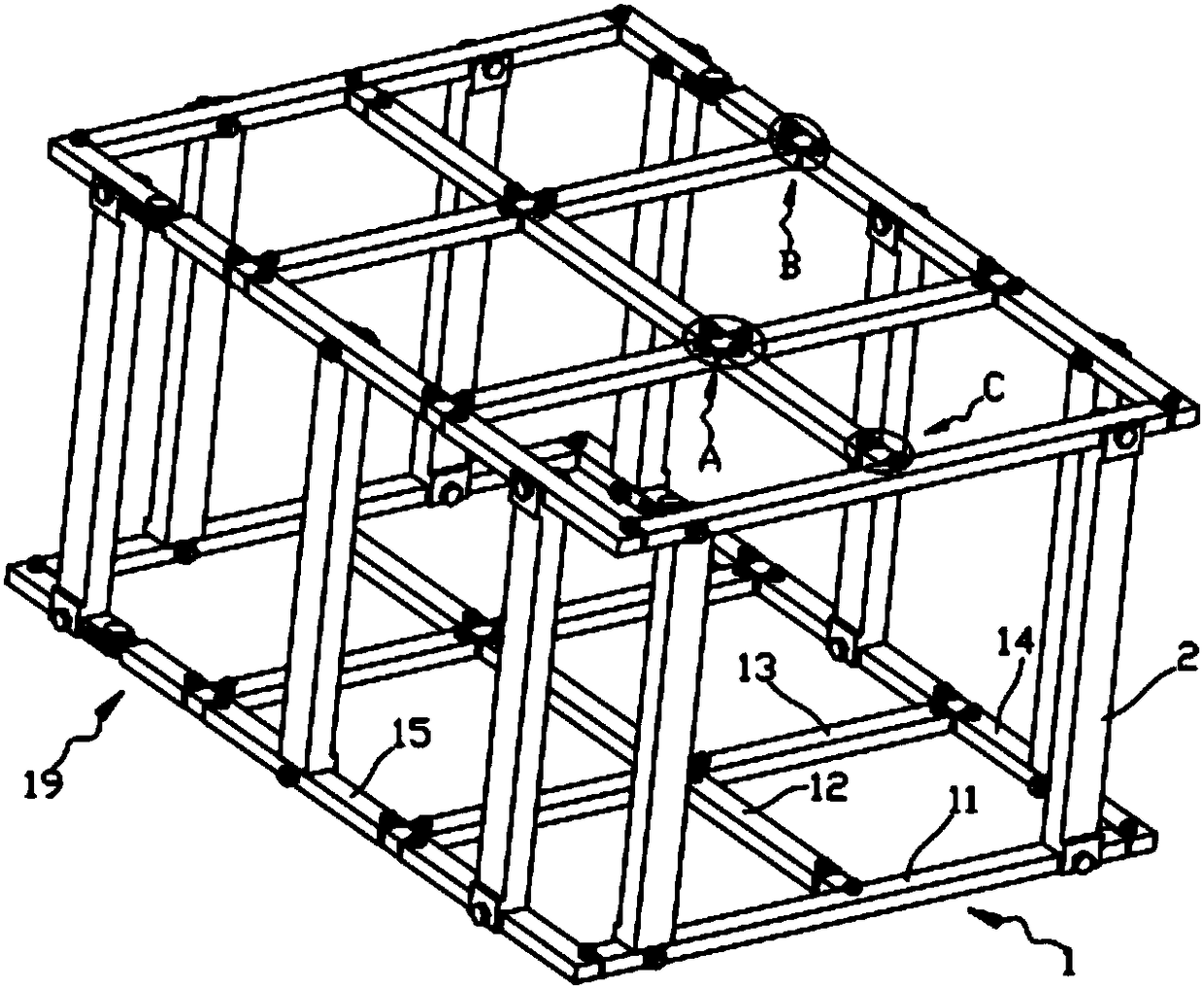

[0038] see Figure 1 to Figure 8 , the present invention provides a technical solution:

[0039] A modular steel structure house, including a frame structure 1 and supporting steel plates 2, wherein:

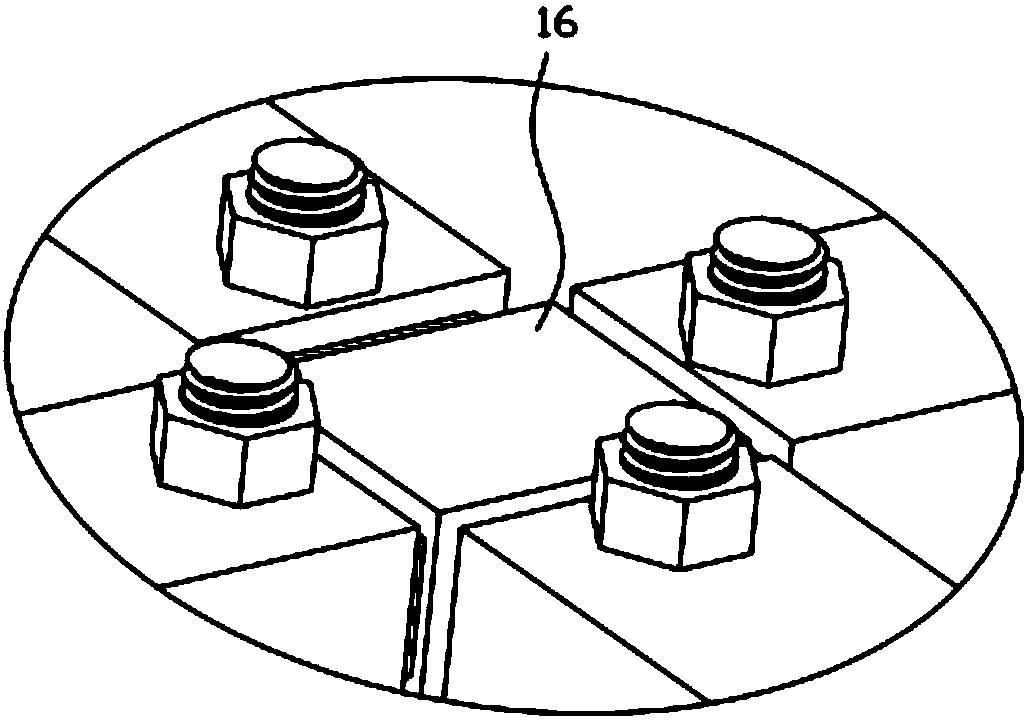

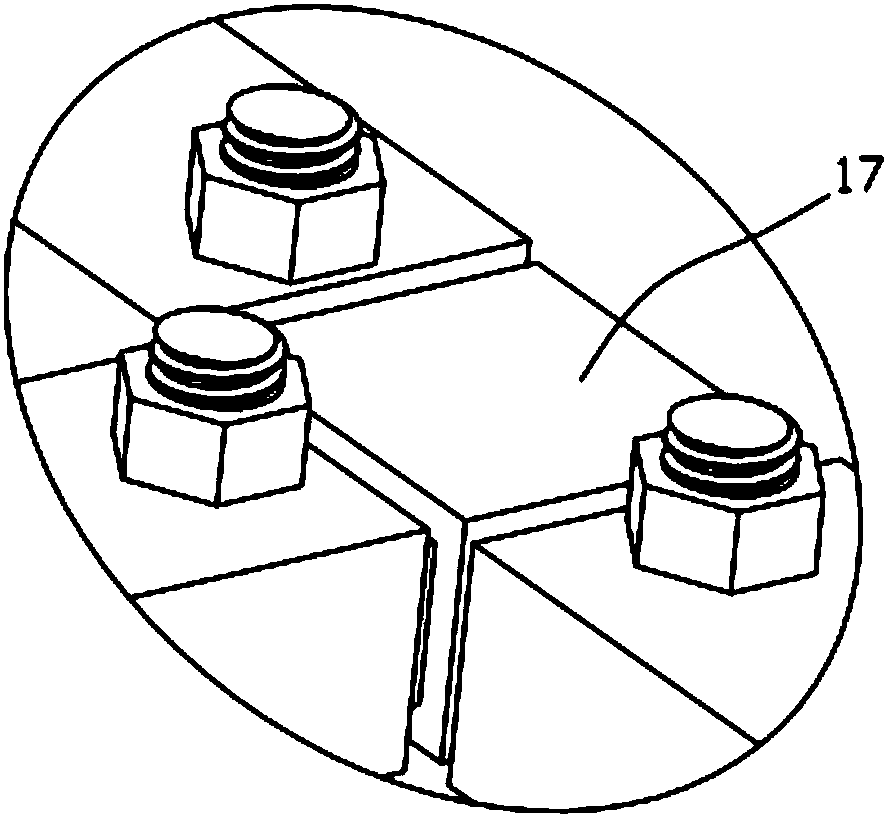

[0040]The two ends of several supporting steel plates 2 are respectively fixed and installed on two frame structures 1 by bolts, so that the two frame structures 1 are fixedly connected. The frame structure 1 includes support rods I11, support rods II12, support rods III13, and support rods IV14 , support rod V15, cross-shaped connecting frame 16, T-shaped connecting frame 17, inline connecting frame 18 and rotating supporting rod 19, there are two supporting rods I11, and the two ends of one supporting rod I11 are respectively fixed and installed by bolts. The supporting rod IV14 and the middle part are installed with a supporting rod II12 through the in-line connecting frame 18, and the two ends of the other supporting rod I11 are respectively fixed with bolts to install a ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com