Assembled shear wall with corner and assembled construction method thereof

A shear wall and prefabricated technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of consuming a lot of manpower, material resources and time, affecting the safety of building structures, water leakage, etc., to shorten the construction period, improve the building assembly rate, Guaranteed continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention is described in detail below in conjunction with accompanying drawing:

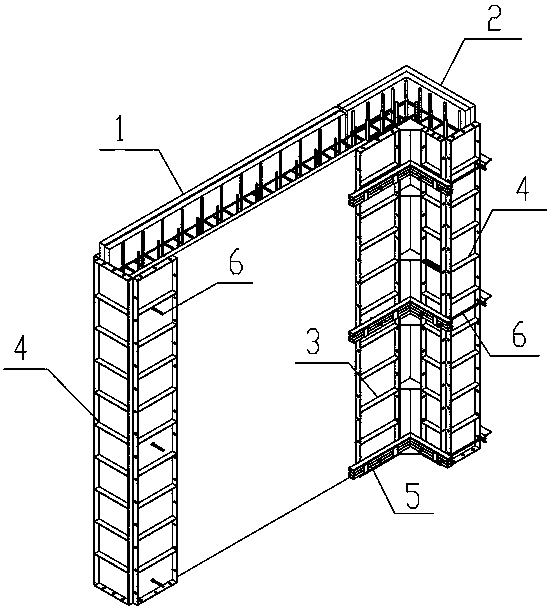

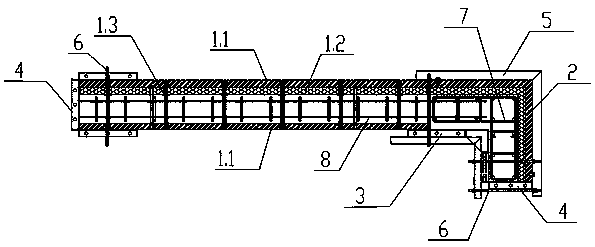

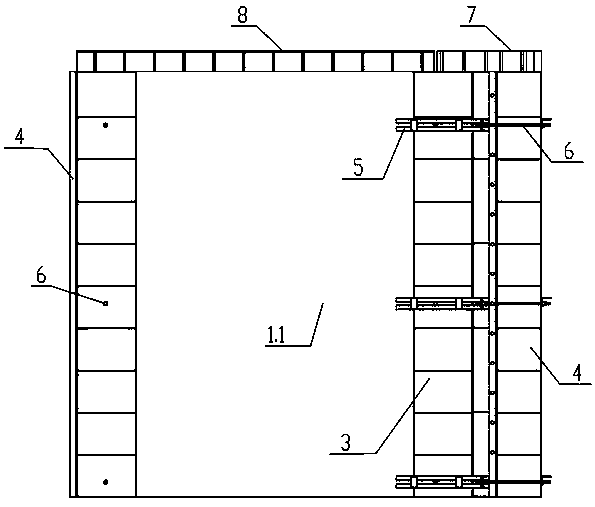

[0044] A prefabricated shear wall with a corner, which includes: a straight-section non-demolition-free concrete formwork 1, an outer PCF board 2 at the corner, an inner formwork 3 at the corner, and an edge-sealing formwork 4 at the end;

[0045] It also includes a fixing device for clamping the outer PCF board 2 of the corner part, the inner formwork 3 of the corner part, and the fixing device for clamping the end edge sealing formwork 4;

[0046] The demolition-free concrete formwork 1 includes concrete slabs 1.1 on the inner and outer sides, and tie rods 1.3 evenly distributed between the two-layer concrete slabs 1.1;

[0047] The fixing device includes shaped steel 5 and tie rods 6, and the shaped steel 5 is symmetrically arranged on the PCF board 2 outside the corner and the formwork 3 inside the corner.

[0048] Wherein if the outer wall has thermal insulation requirem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com