Monitoring Method for Slight Leakage of Valve Cooling System Based on Temperature Compensation and Least Square Method

A least square method and temperature compensation technology, which is applied in liquid tightness measurement using liquid/vacuum degree, measurement device, engine lubrication, etc., can solve problems such as prone to water leakage, numerous interfaces, and difficult to find water leakage points, etc. Achieve the effects of improving stability, broadening the application value, and reducing unplanned power outage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

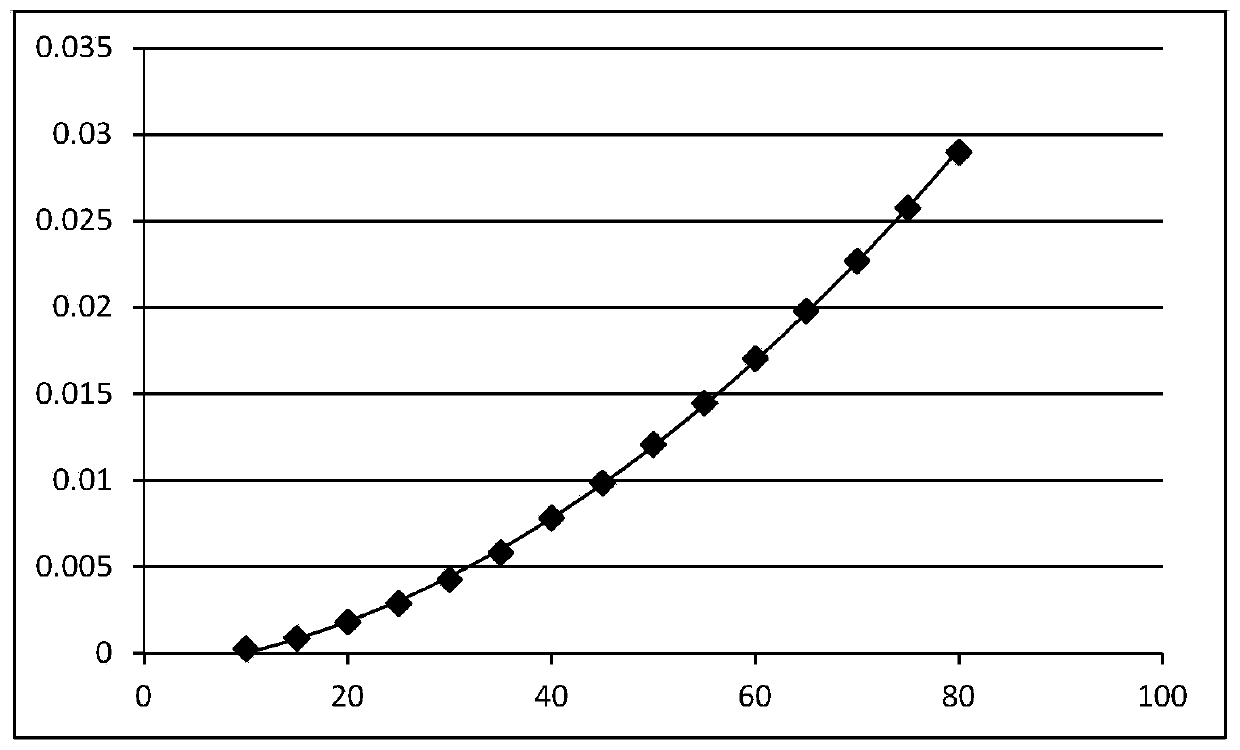

Image

Examples

Embodiment

[0030] A method for monitoring slight leakage of a valve cooling system based on temperature compensation and the least squares method, wherein the valve cooling system includes a main circulation pump, a main filter, a diverter valve, an expansion tank, and a cooling tower that are sequentially connected through pipelines and form a loop; The expansion tank is connected to the main circulation pump, and a water level sensor is arranged inside the expansion tank; the specific steps of the monitoring method are as follows:

[0031] Step 1. The water in the internal cooling water pipeline can be divided into the water flowing into the diverter valve and the water flowing out of the diverter valve according to the temperature; let the total volume of the inner cooling water be V, and the water inlet volume of the diverter valve be V in , the water outlet volume of the diverter valve is V out , the internal cooling water pipeline capacity is V n , due to the internal cooling wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com