Method for influencing the lightening current distribution in electrical systems, which are integrated in rotor blades of wind turbines

A technology of wind power generators and rotor blades, applied in the direction of wind power generators, wind power generators consistent with the wind direction, wind power generation, etc., can solve the problems of damage to electrical components, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

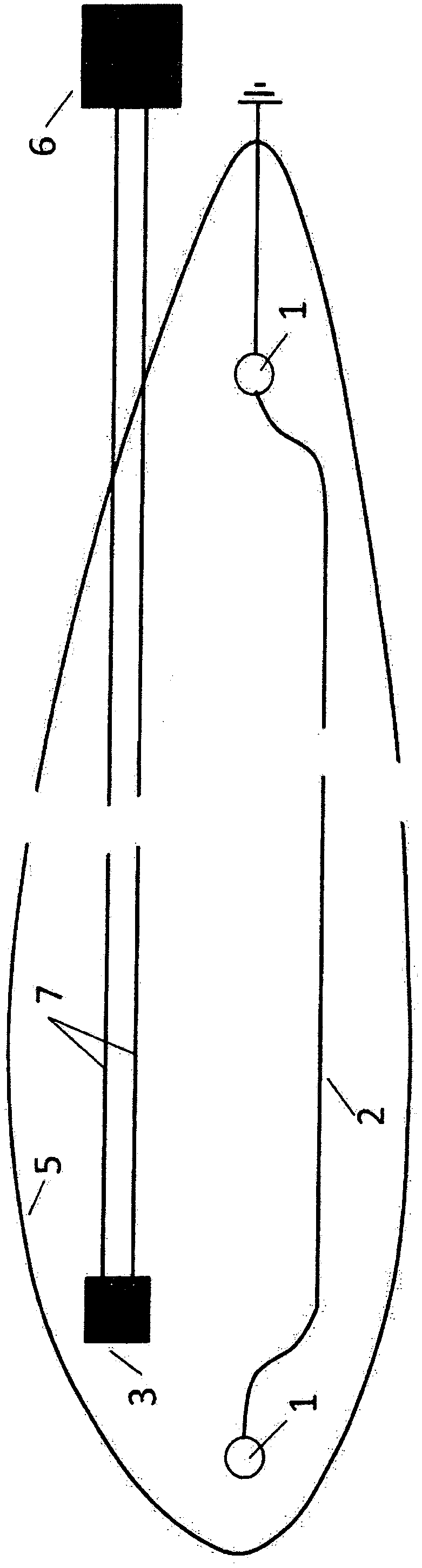

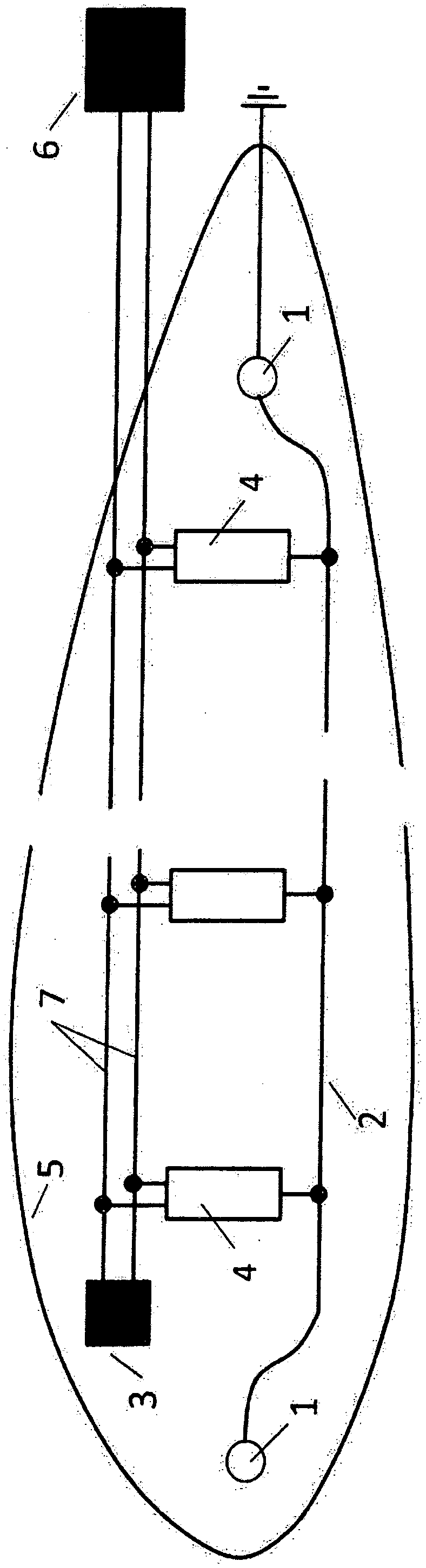

[0023] according to figure 1 and 2 The illustration takes the rotor blade 5 of the wind turbine as a starting point.

[0024] For example, two receivers 1 are formed in the rotor blade 5 as lightning protection elements. A ground wire is provided between the receivers 1 as a discharge device, which can direct the lightning current to the ground. The electrical system, in particular the consumer 3 for heating the rotor blades, is connected to an external power source 6 via a power supply line 7 .

[0025] The actual separation distance between the power line 7 and the ground line 2 or the discharge device is less than or equal to 1m. figure 1 as indicated by the symbol.

[0026] The actual required separation distance s according to EN 62305-3 is as follows:

[0027] S=k i ·k c / k m ·l

[0028] in,

[0029] k i = 0.08 (for LPL1)

[0030] k m = 1.0 (for air)

[0031] k c =1.0 (for n=1) (number of discharge devices)

[0032] l=50m.

[0033] Therefore, the separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com