Semi-tubular self-piercing rivet for thin sheet metal joints, method for producing said semi-tubular self-piercing rivet, and method for producing a joint

A semi-hollow, rivet technology, applied in the direction of thin plate connection, rivet, connection member, etc., can solve the problems affecting the riveting of the upper aluminum plate, and achieve the effect of reliable attachment and avoidance of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

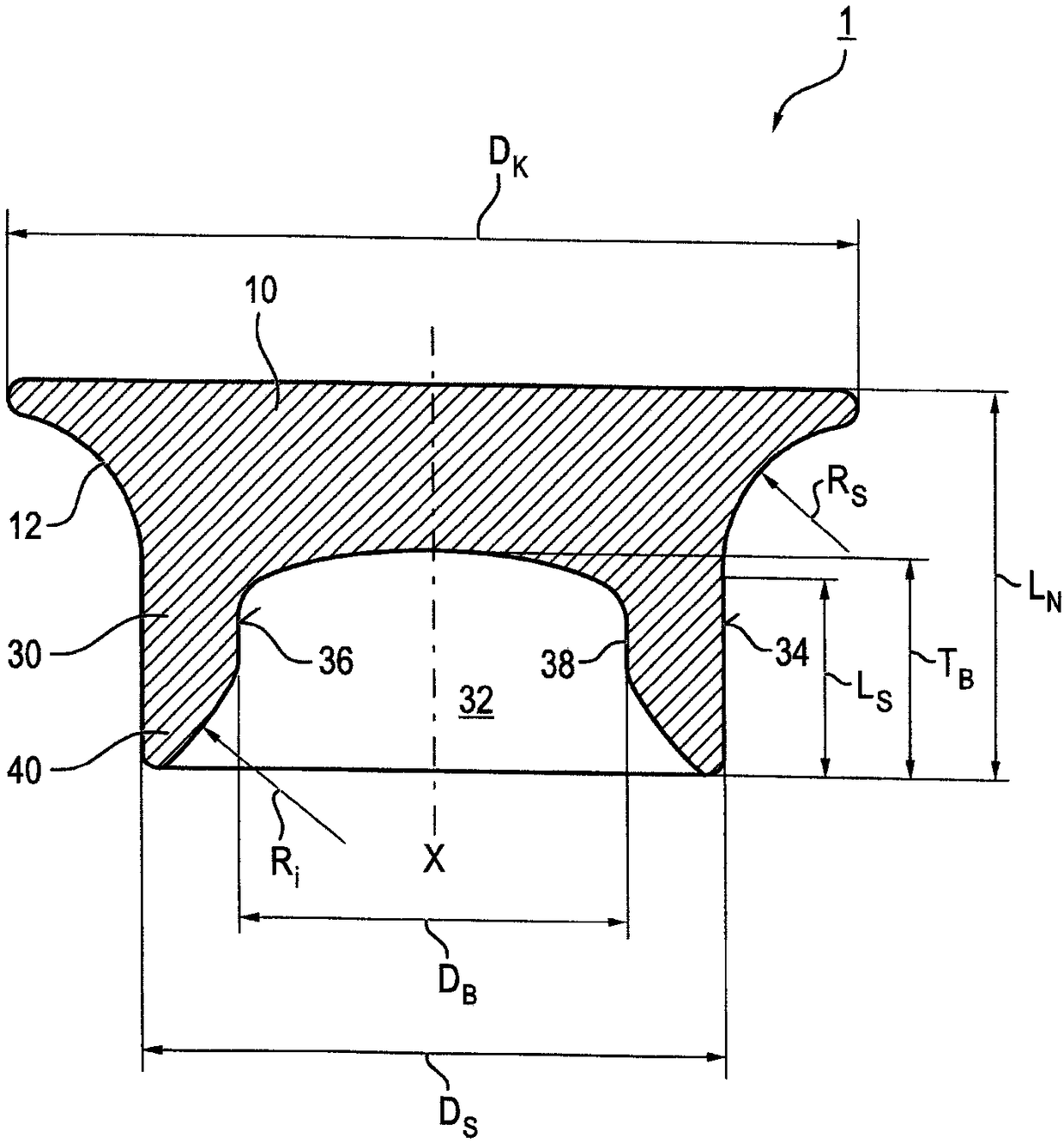

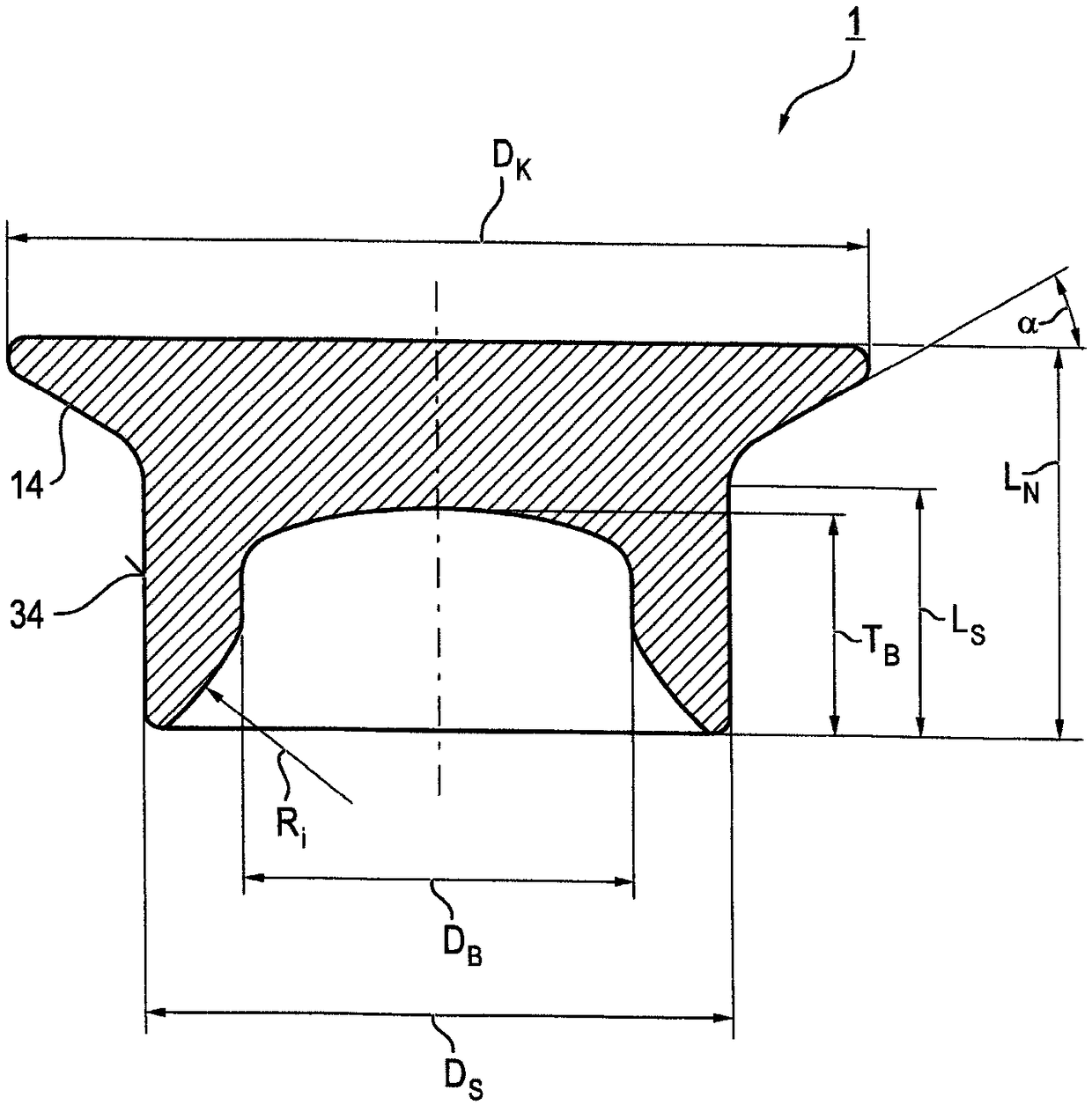

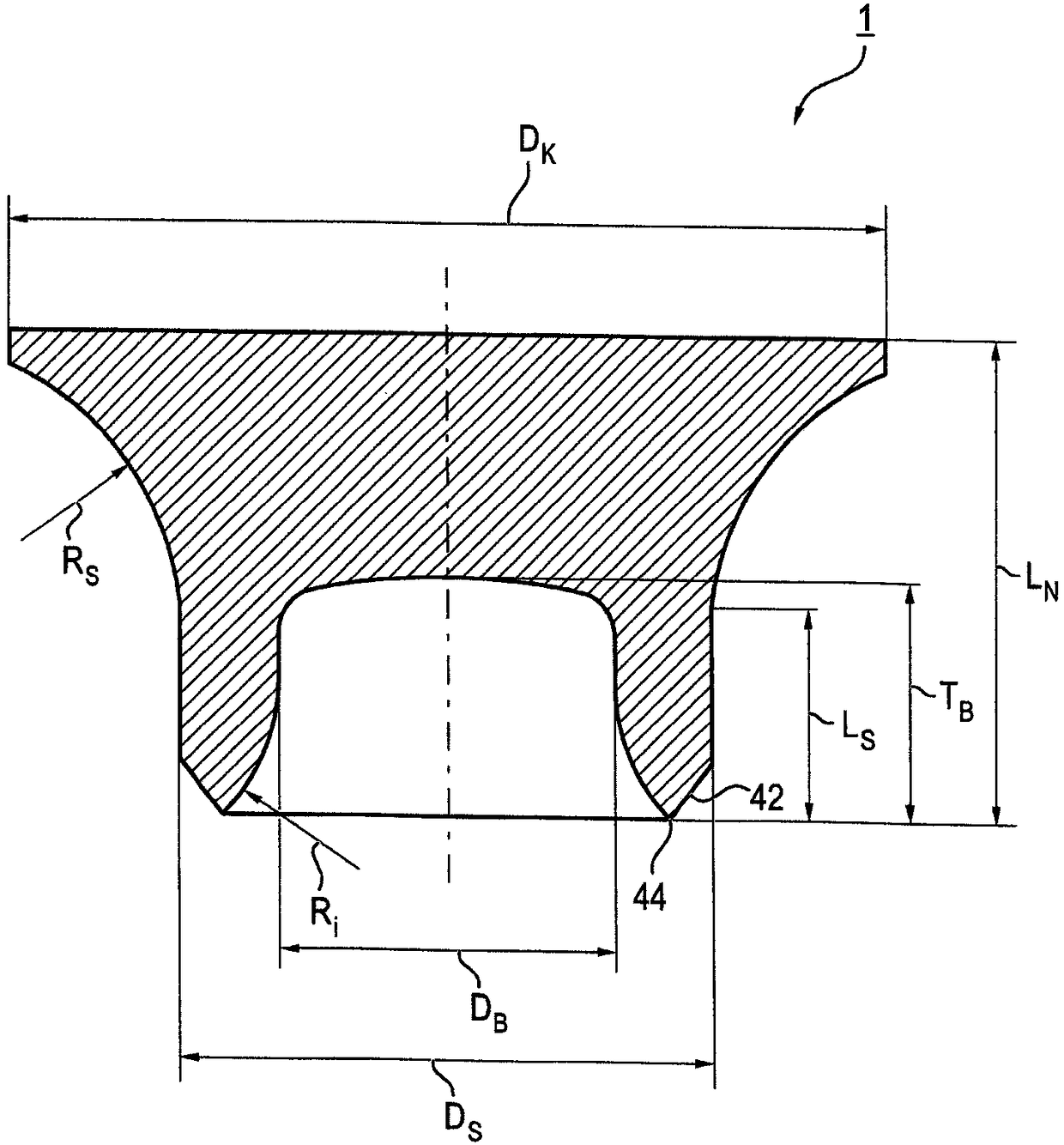

[0041] The semi-hollow self-piercing rivet 1 according to the invention is produced from a wire blank by cold forming. It has the geometrical characteristics detailed below. Such as figure 1 Referring to the inventive preferred embodiment of the semi-hollow self-piercing rivet 1 shown in FIG. 3 , the latter comprises a rivet head 10 with a common central axis X and a rivet shaft 30 with a central shaft hole 32 . Rivet shaft 30 has an outer shaft face 34 and an inner shaft face 36 defining a central shaft bore 32 . The shaft hole 32 has a depth T B , and the semi-hollow self-piercing rivet 1 has a total length L N . The semi-hollow self-piercing rivet according to the invention is preferably used on a plurality of sheets B 1 , B 2 A self-piercing rivet connection is produced in a stack of ... (see Figure 4 ), the sheets B1, B2 have a thickness t 1 , t 2 . For this purpose, the semi-hollow self-piercing rivet 1 has L N A total length of ≦4 mm, wherein the outer axial...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com