Grate plate for a grate cooler

A cooler and grate plate technology, which is applied in the direction of processing discharged materials, furnaces, lighting and heating equipment, etc., can solve the problems of unfavorable, increased flow resistance, pressure loss, and insufficient reduction, and achieve simple structure and improved Effect of air inflow velocity, reduction of flow resistance or pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

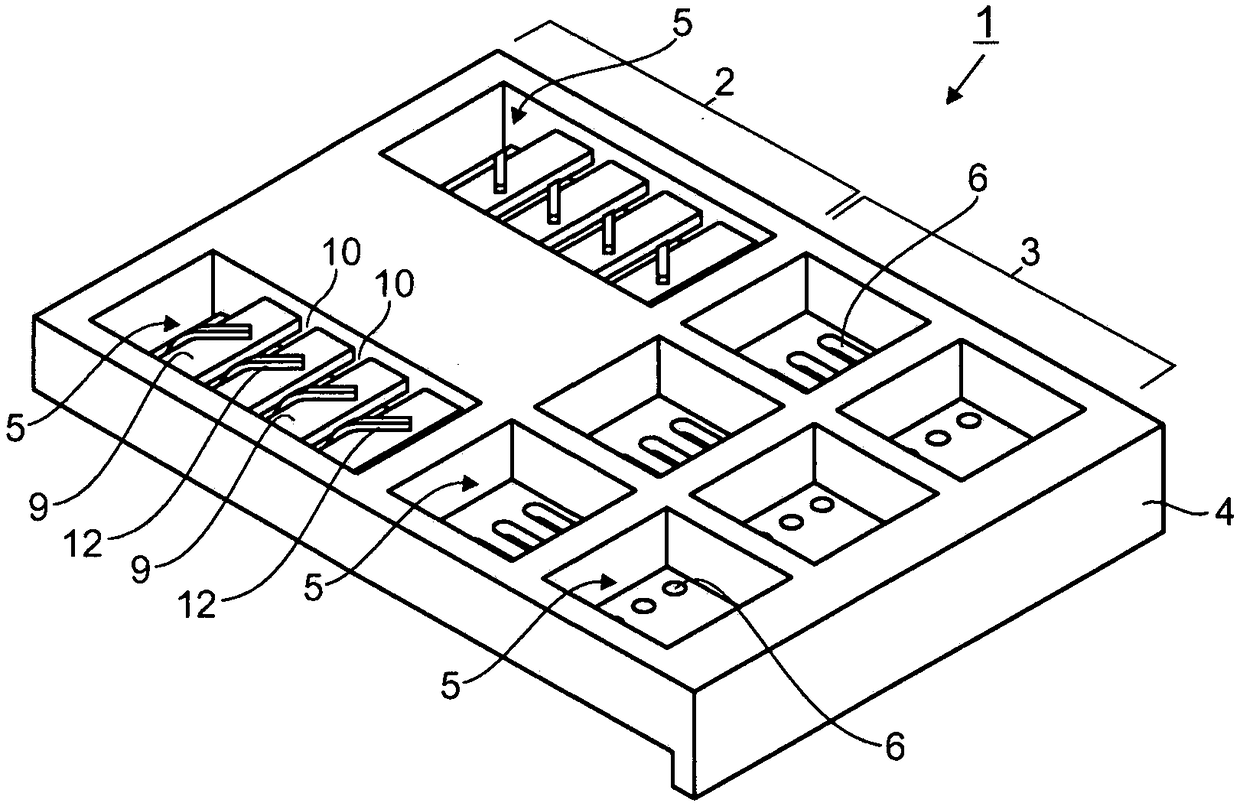

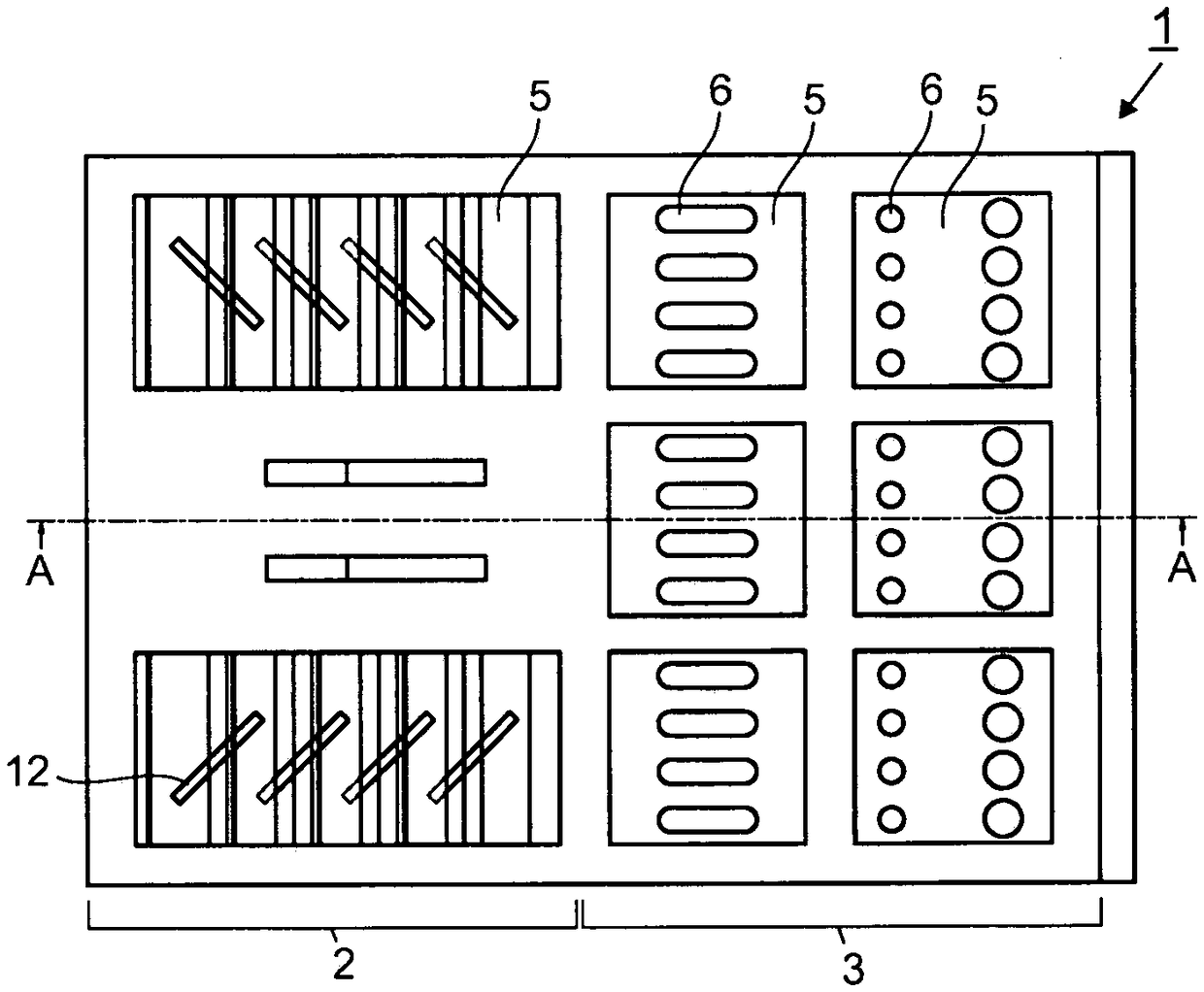

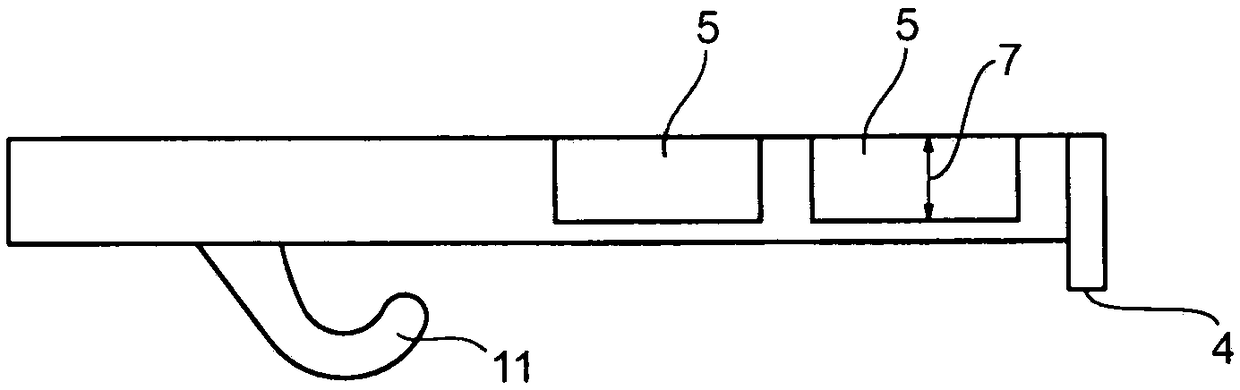

[0028] exist figure 1 shows a grate plate 1 according to the invention, the upper side of which is composed of a first working area (covered area 2 ) and a second working area (uncovered area 3 ). When the grate 1 is installed in a grate cooler, hot bulk material (not shown) falls from the grate steps above the grate onto the cover area 2 and from there through the grate 1 above it The oscillating to-and-fro movement of is pushed into the uncovered area 3 . exist Figure 4 in (and in Figure 5 Middle) shows the interrelationship of two such stepped grate plates 1 . In this case, movably mounted grate rows alternate with statically fixed grate rows on successive steps. For example, in the illustration the upper grate 1 can be assumed to be movable and carry out an oscillating drive movement, while the lower grate 1 is stationary. In this way, loose material (not shown) falling from the upper grate 1 into the covering area 2 of the lower grate 1 is pushed into the lower gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com