Multi-station automatic inner corner chamfering machine

An inner corner machine and multi-station technology, applied in the field of chamfering, can solve the problems of chamfering the inner wall of the workpiece, troublesome post-maintenance, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

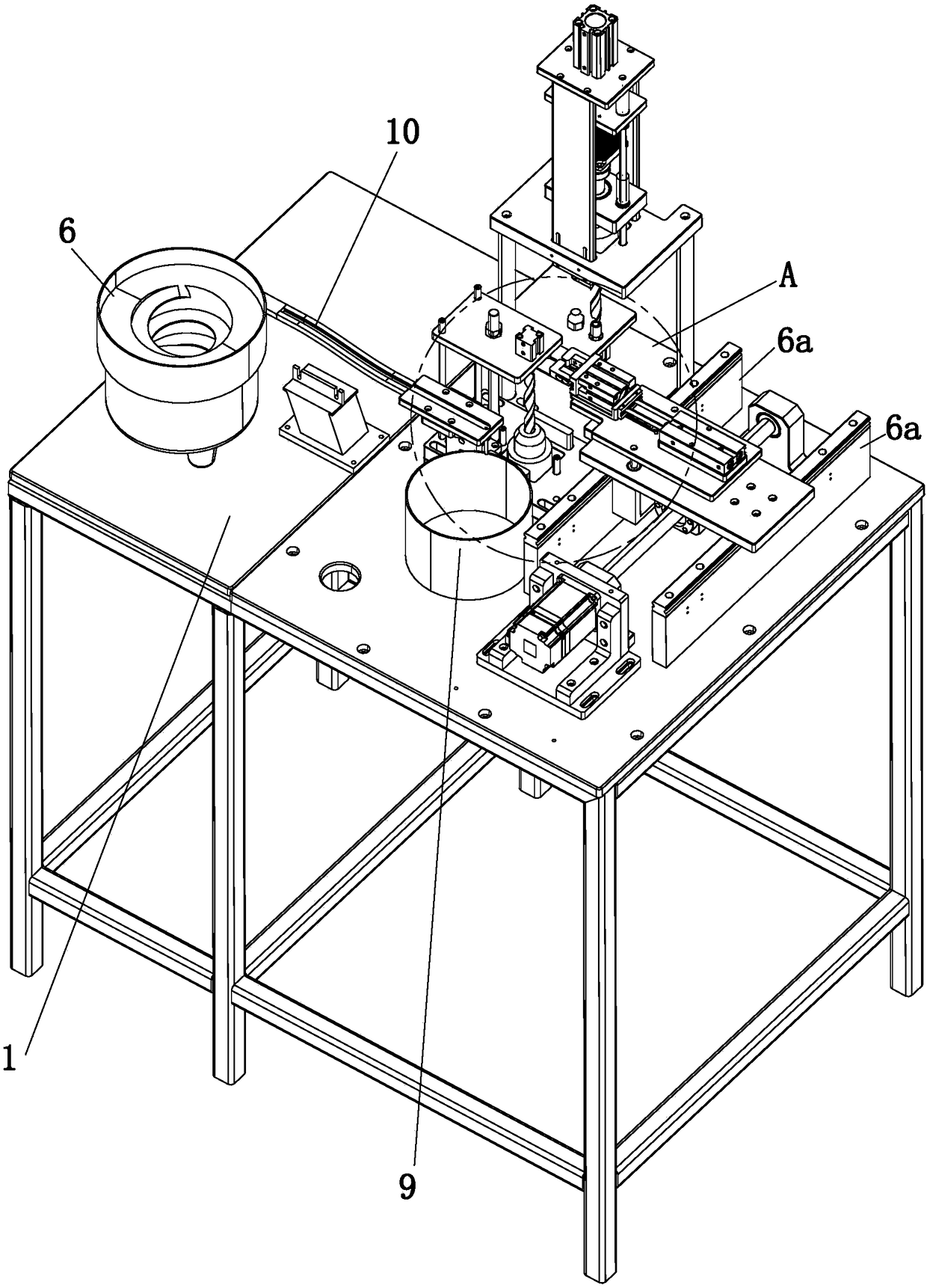

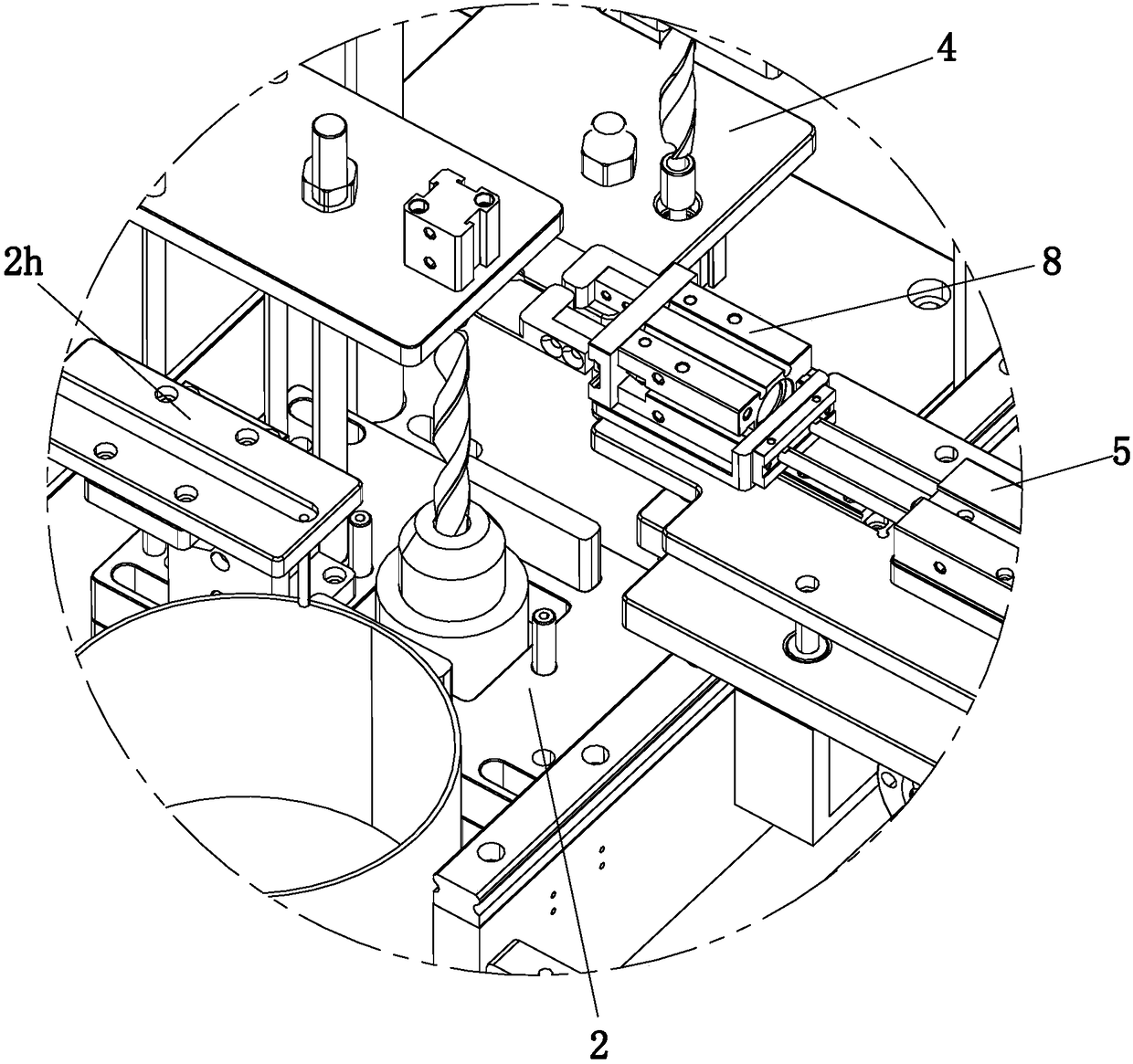

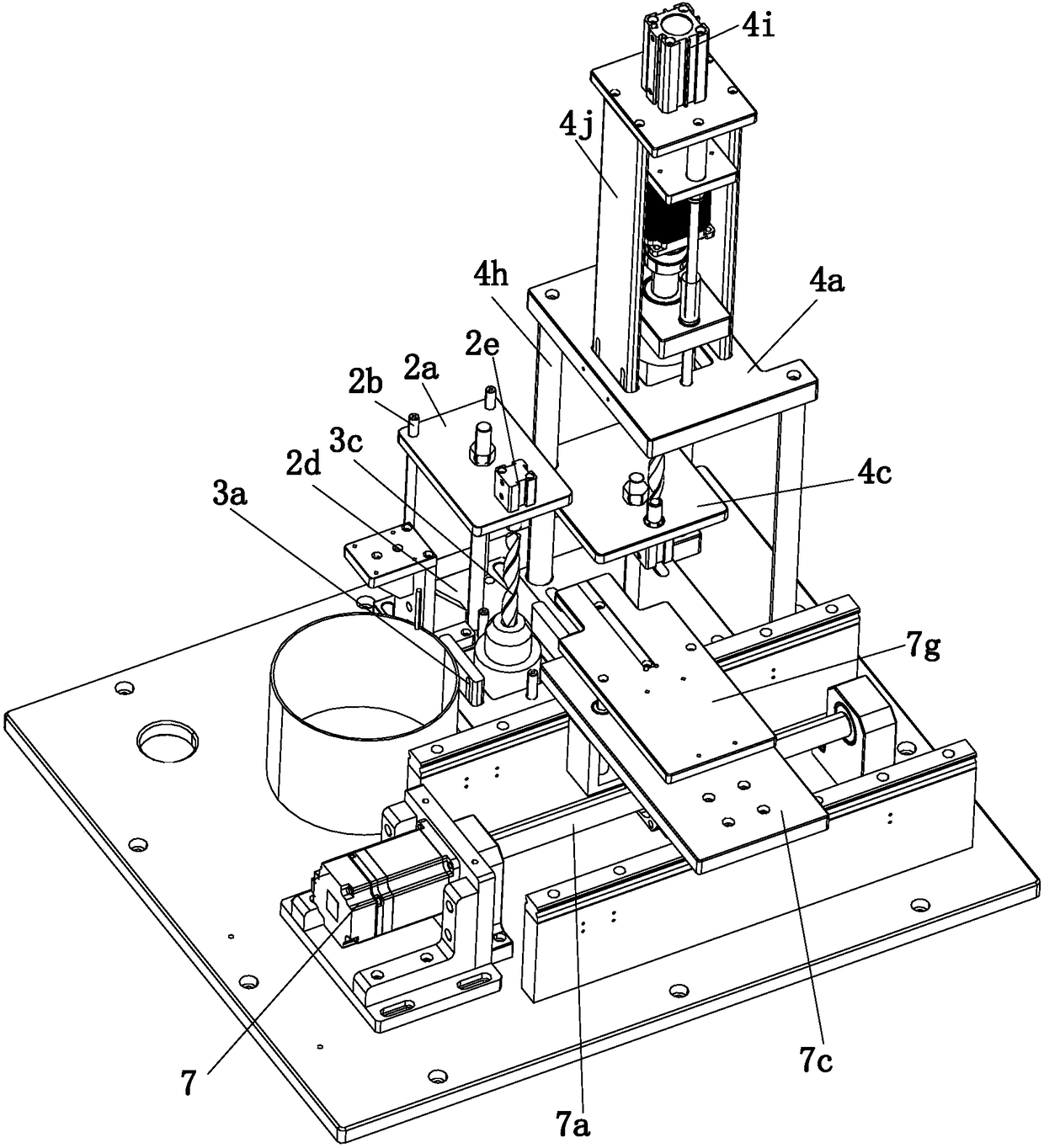

[0021] refer to Figure 1 to Figure 7The shown multi-station automatic chamfering machine includes a working platform 1, an upper processing part 2, a lower processing part 4 and feeding parts for feeding the upper processing part 2 and the lower processing part 4, and the working platform 1 The working plane of the working platform is a rectangular structure. One end in the width direction of the top of the working platform 1 is provided with a vibrating plate 6, and the other end is provided with two symmetrical feeding guide plates 6a. The feeding parts include a feeding cylinder 5, which can slide horizontally. Between the two feeding guide plates 6a, a lifting cylinder 5a is also provided below the feeding cylinder 5, the upper processing part 2 is arranged above the center of the working platform 1, and the lo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap