Machine tool table face large mass framework fine positioning tool

A fine positioning and high-quality technology, which is applied in the field of fine positioning of the large-mass frame of the machine tool table, can solve the problems of heavy workload, knocking on one side and the other side will follow, and reduce the surface quality of the product, so as to achieve fast and accurate positioning, The effect of improving product quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below.

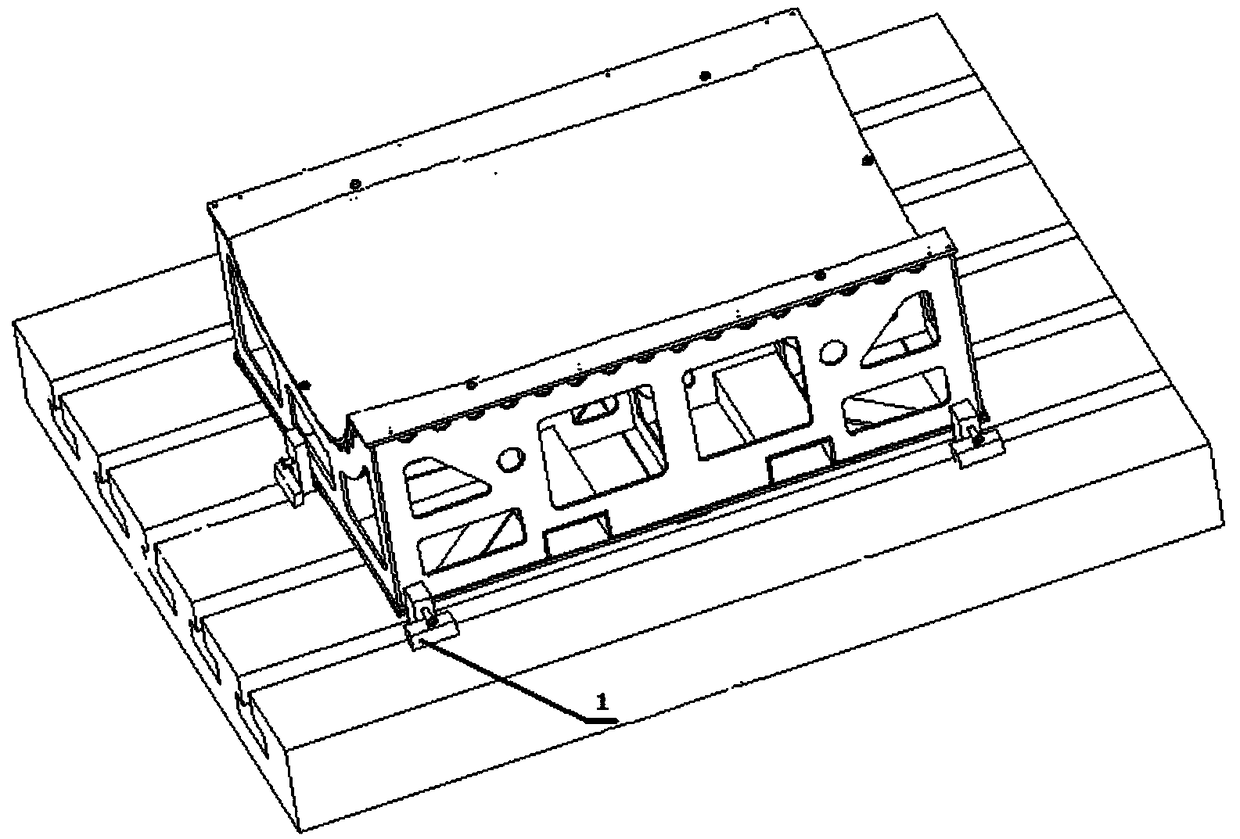

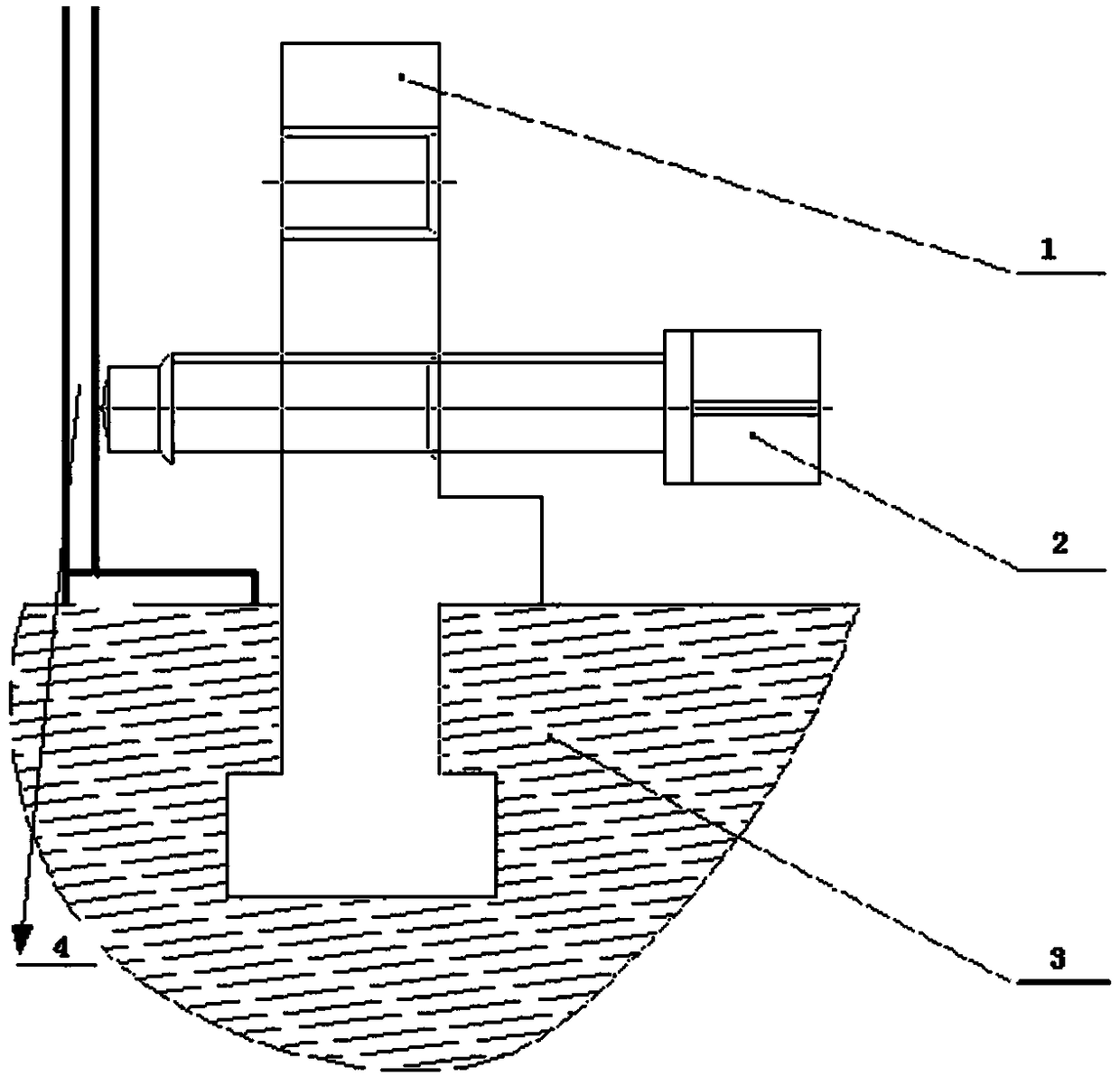

[0019] A fine positioning tool for a large-mass frame on a machine tool table is provided, which includes a bracket and a fine positioning adjustment rod; a threaded hole is opened on the support, an external thread is arranged on the fine positioning adjustment rod, and the fine positioning adjustment rod is connected to the bracket thread through the external thread Hole thread matching; rotating the fine positioning adjustment rod can realize reciprocating axial movement; one end of the fine positioning adjustment rod is the end of the force, and the other end is the handle; the bottom of the bracket has a T-shaped slider, and the T-shaped slider is slidingly matched with the T-shaped slot on the machine table ; A ball is arranged between the T-shaped slide block and the T-shaped groove of the machine table; a scale is arranged on the fine positioning adjustment rod, which corresponds to the moving dis...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap