A leaf spring variable stiffness flexible actuator based on rack and pinion transmission

A flexible drive, rack and pinion technology, used in transmissions, belts/chains/gears, program-controlled manipulators, etc., can solve the problems of slow control response of the drive and insufficient compact structure of the drive, and achieve compact structure design and excellent mechanical properties. , highly symmetrical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention provides a leaf spring type variable stiffness flexible driver based on rack and pinion transmission. The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

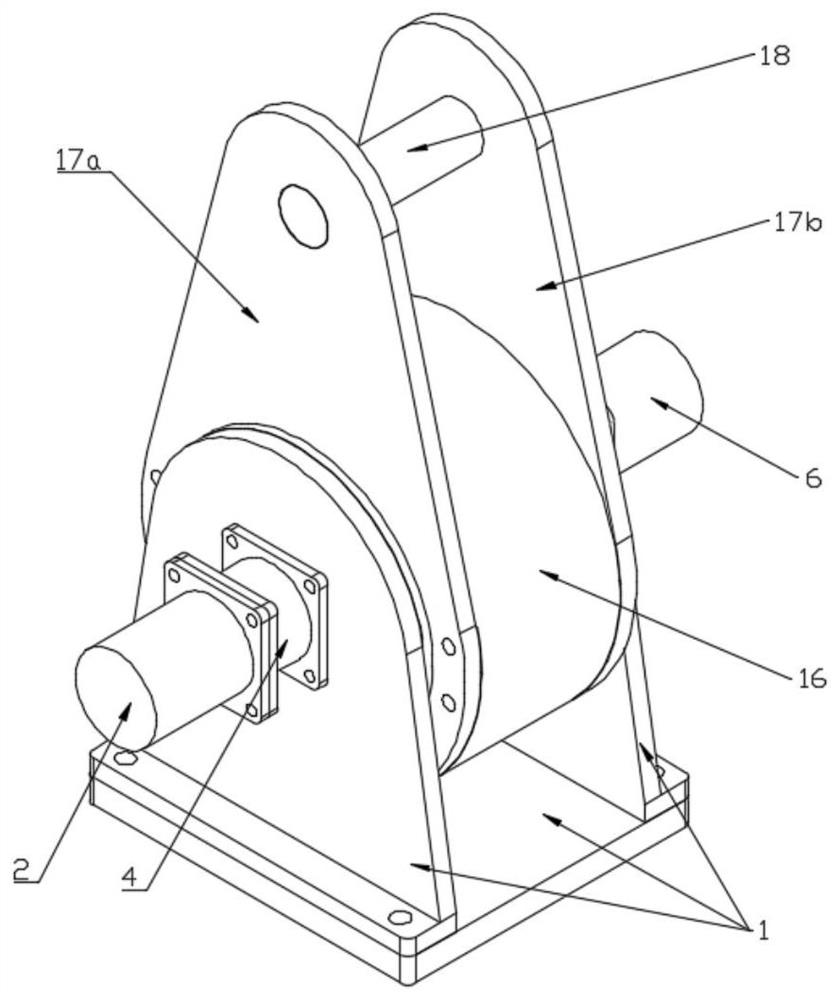

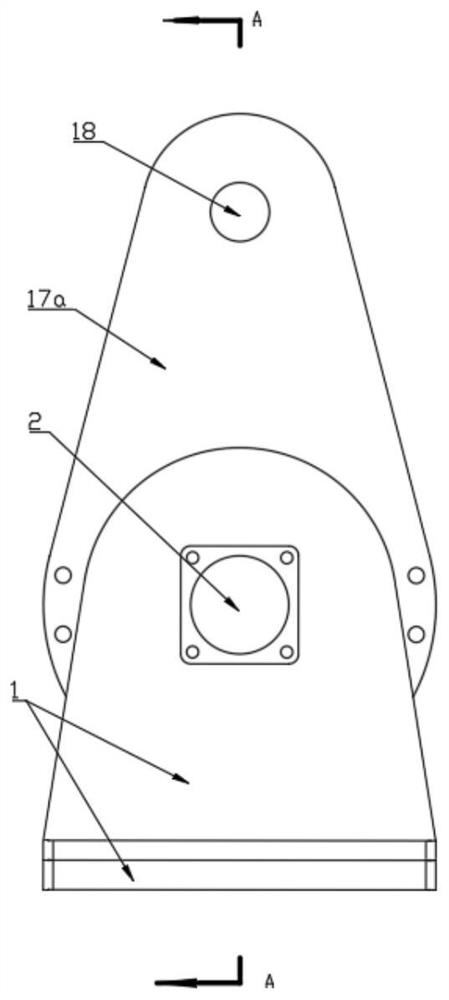

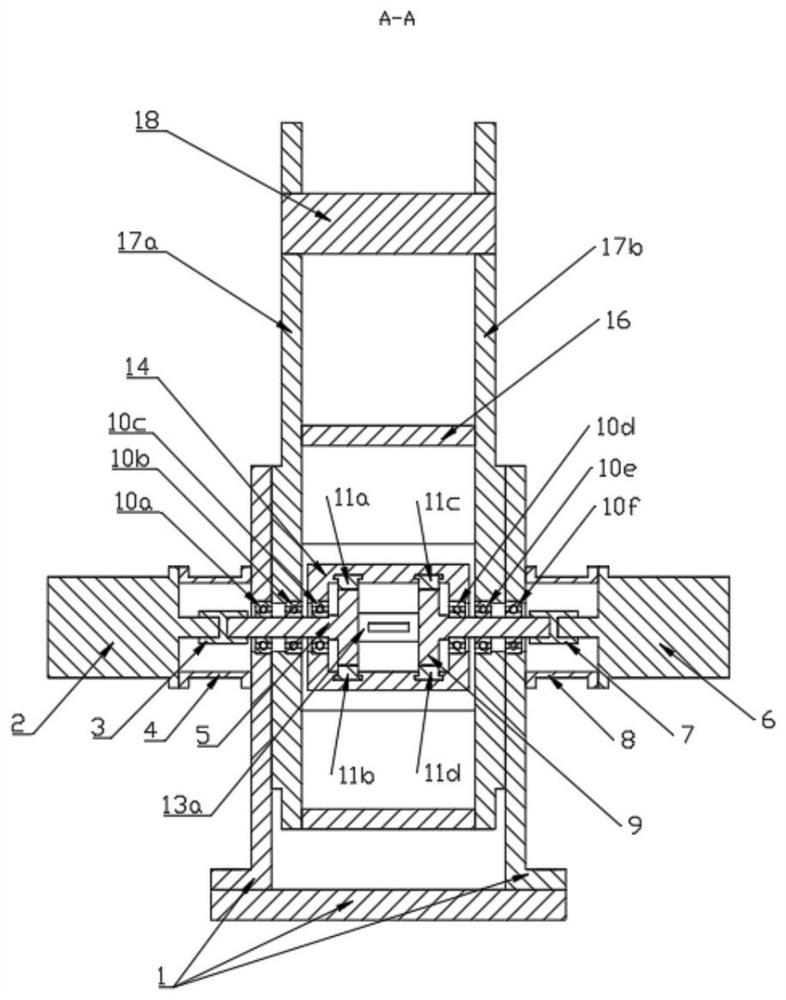

[0020] figure 1 It is a schematic diagram of the overall structure of an embodiment of the present invention, Figure 2a , 3a They are respectively the left view and the front view of the embodiment of the present invention. The described leaf spring variable stiffness flexible driver based on rack and pinion transmission includes a frame 1, a power input and transmission mechanism, and an output mechanism. This driver comprises A motor 2, B motor 6, A motor bracket 4, B motor bracket 8, A coupling 3, B coupling 7, A gear 5, B gear 9, the first A rack 11a, the second A rack 11b, first B rack 11c, second B rack 11d, first A link 12a, second A link 12b, first B link 12c, second B link 12d, first slider Block 13a, second slide blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com