Automatic embedment injection molding production line for bearing roller

A production line and bearing technology, which is applied in the field of automatic bearing roller embedded injection molding production line, can solve the problems such as long operation time of manually inserting bearings and removing bearing rollers, unfavorable automatic and mechanized production of bearing rollers, affecting product quality stability and production efficiency, etc. Achieve the effect of improving quality stability and product qualification rate, realizing production automation, and leveling the cutting surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

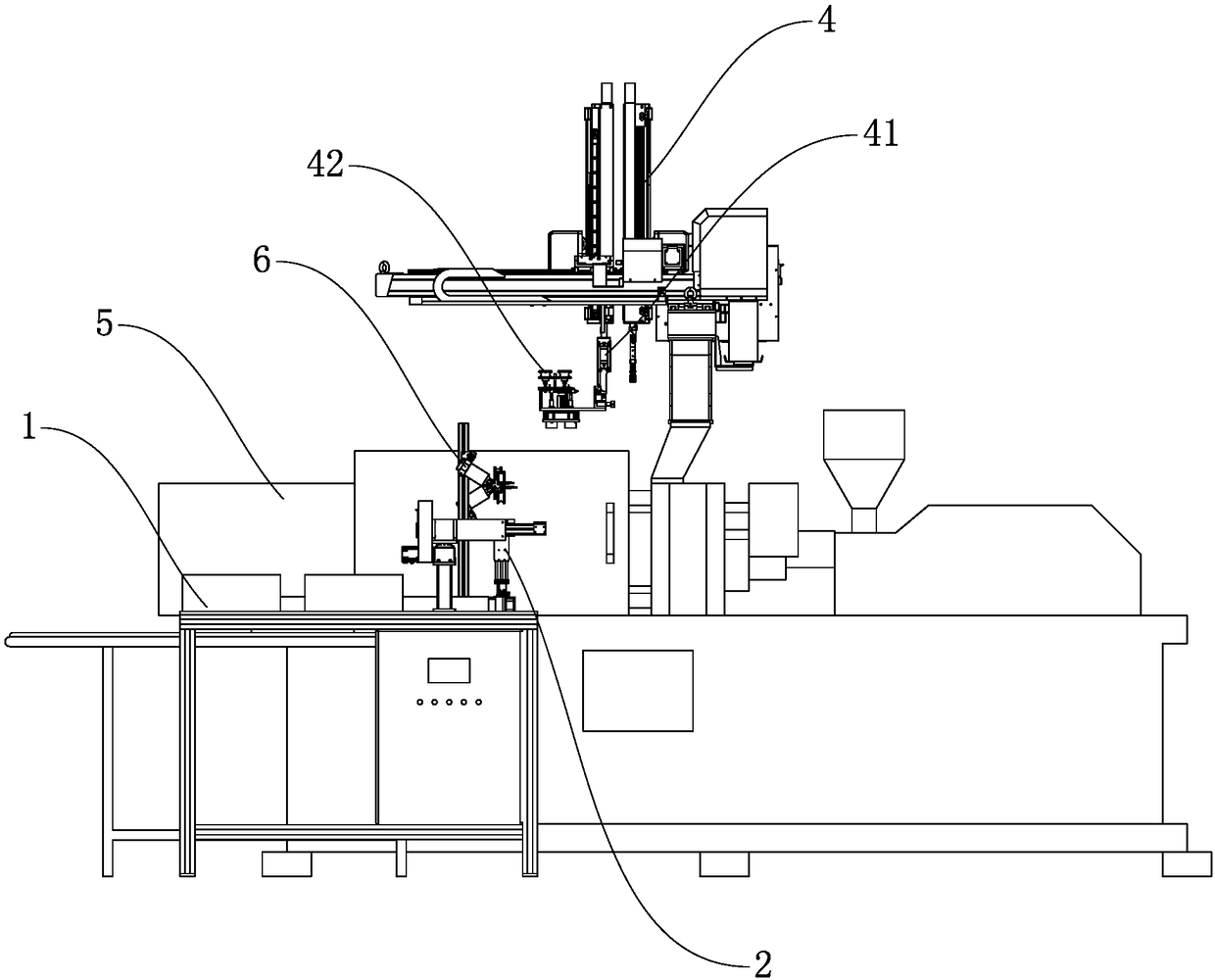

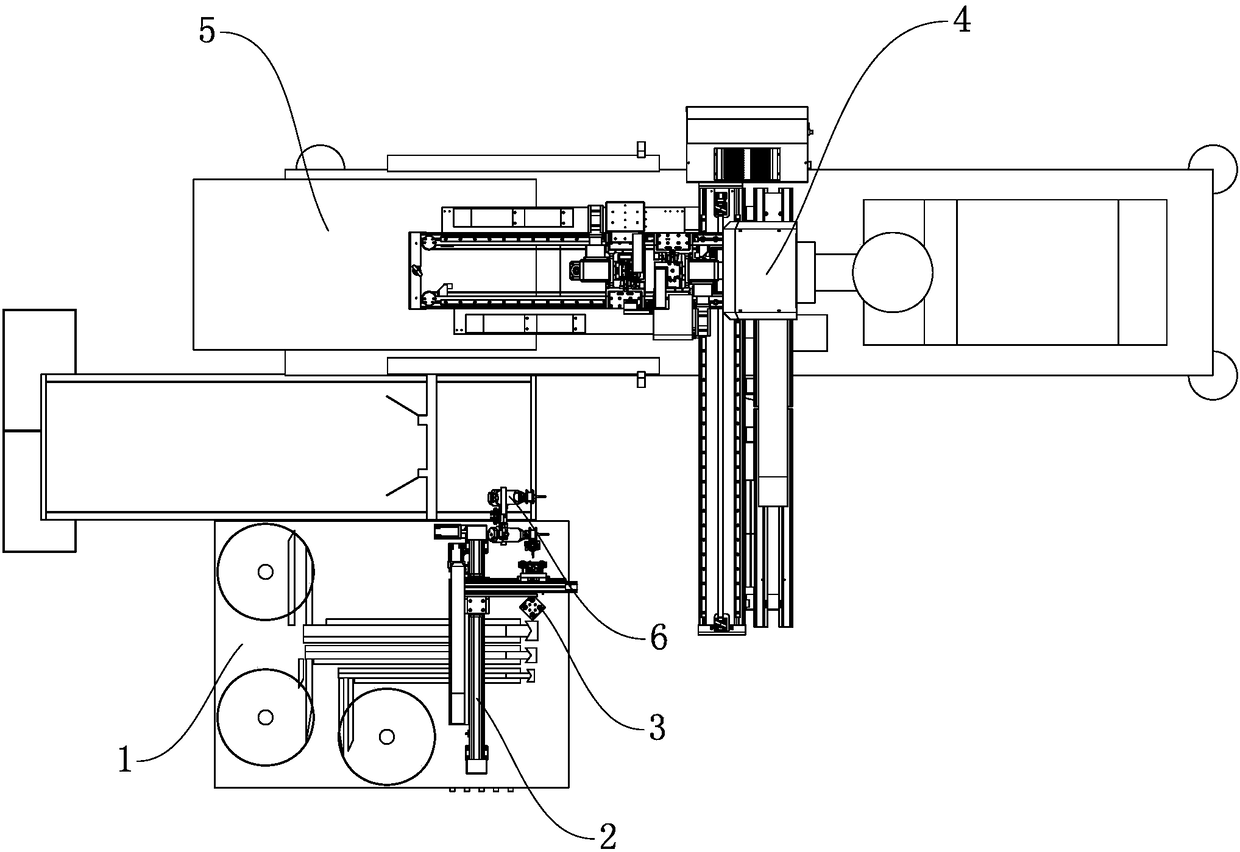

[0034] Embodiment 1: As shown in the figure, a bearing roller is automatically embedded in an injection molding production line, including: a bearing feeding device 1 , a bearing grabbing device 2 , a bearing positioning device 3 , a manipulator 4 , an injection molding machine 5 and a nozzle shearing device 6 . The bearing feeding device 1 provides the bearings 7 arranged automatically and orderly, the bearing grabbing device 2 takes out the arranged bearings 7 from the bearing feeding device 1 and transfers them to the bearing positioning device 3 for positioning, and the manipulator 4 positions the bearings from the bearing Take out the positioned bearing 7 from the device 3, transfer it and insert it into the mold of the injection molding machine 5 for injection molding, and the manipulator 4 takes out the injected bearing roller 8 output from the demoulding side of the injection molding machine 5, and transfers it to the nozzle for shearing Device 6, the nozzle shearing de...

Embodiment 2

[0035] Embodiment 2: As shown in the figure, a bearing roller is automatically embedded in an injection molding production line, including: a bearing feeding device 1 , a bearing grabbing device 2 , a bearing positioning device 3 , a manipulator 4 , an injection molding machine 5 and a nozzle shearing device 6 . The bearing feeding device 1 provides the bearings 7 arranged automatically and orderly, the bearing grabbing device 2 takes out the arranged bearings 7 from the bearing feeding device 1 and transfers them to the bearing positioning device 3 for positioning, and the manipulator 4 positions the bearings from the bearing Take out the positioned bearing 7 from the device 3, transfer it and insert it into the mold of the injection molding machine 5 for injection molding, and the manipulator 4 takes out the injected bearing roller 8 output from the demoulding side of the injection molding machine 5, and transfers it to the nozzle for shearing Device 6, the nozzle shearing de...

Embodiment 3

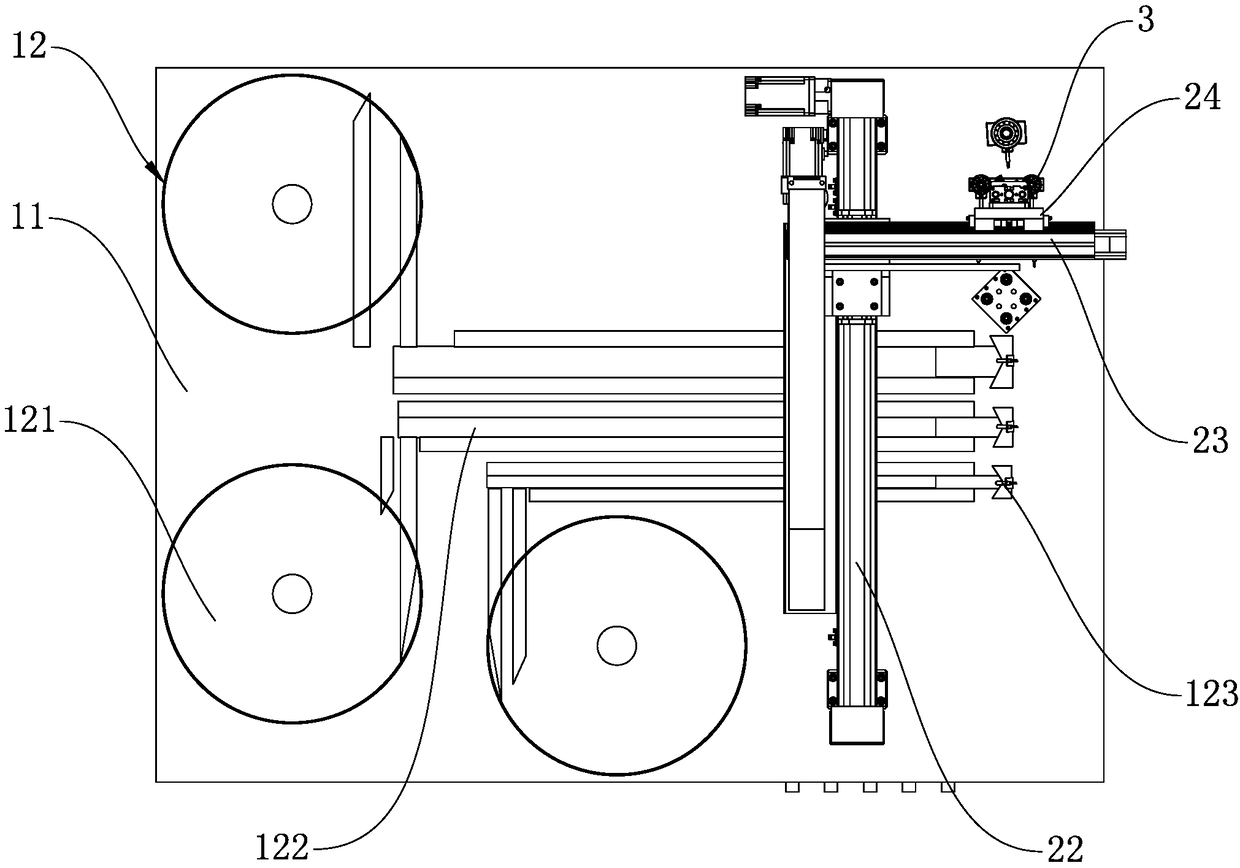

[0046] Embodiment 3: As shown in the figure, a bearing roller is automatically embedded in an injection molding production line. The difference from Embodiment 2 is that the bearing positioning device 3 includes a positioning block assembly 31 fixed above the feeding platform 11, and the positioning block assembly 31 includes A positioning block 311 and four positioning pins 312 . The positioning block 311 is fixed above the feeding platform 11 , and the positioning pins 312 are arranged vertically and symmetrically on the positioning block 311 for positioning the inner rings of the four bearings 7 respectively. The position of the positioned bearing 7 on the positioning block 311 , the position of the bearing 7 absorbed on the manipulator 4 and the position of the bearing 7 embedded in the injection mold all correspond to each other.

[0047] In this embodiment, the positioning block assembly 31 also includes a buffer mechanism, which is a spring (not shown) arranged between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com