Full-automatic PE plate slitting device

A fully automatic, plate technology, applied in metal processing, etc., can solve the problems of continuous production, low production efficiency and energy consumption by manual operation, and achieve the effect of realizing production automation, improving production efficiency and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

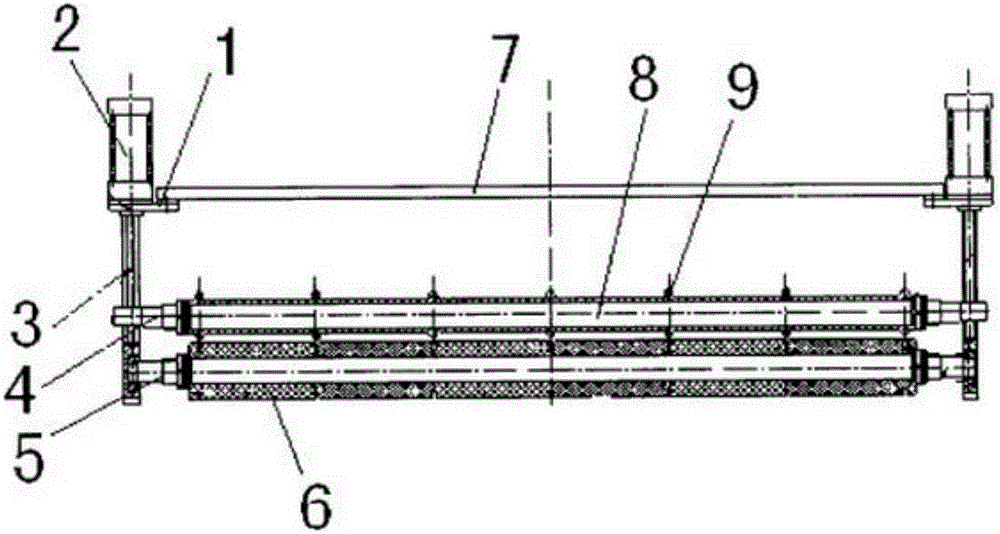

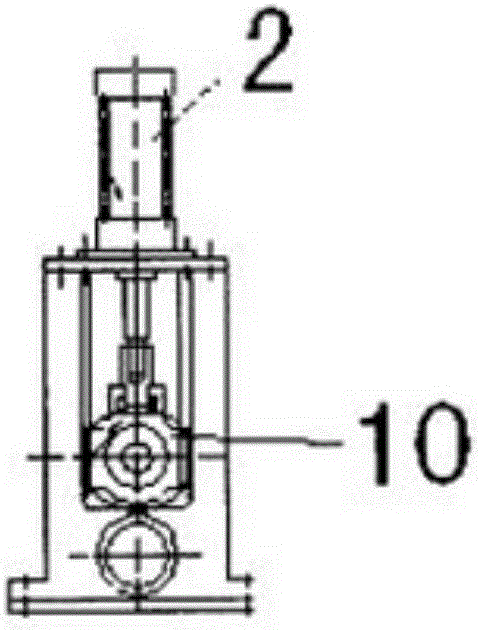

[0012] refer to Figure 1-Figure 2 , the full-automatic PE plate cutting device of the present embodiment, it comprises knife rest device, cutting device, and cutting device comprises cutter device, idler device, and cutter device is connected with knife rest device by belt slider seat ball bearing 10. The gantry frame 3 is fixedly connected, and the roller device is fixedly connected to the gantry frame 3; the cutter device is slidably connected to the gantry frame 3 of the knife holder device through a ball bearing 10 with a slider seat, and the roller device is clamped on both sides of the gantry frame through bearings. 3, it can rotate axially; the cutter device includes a cutter shaft 4, a cutter pad 8, and a cutter 9, and the cutter pad 8 and the cutter 9 are fixedly arranged on the cutter shaft 4 alternately; The supporting roller device includes a lower cutter shaft 5 and a supporting roller 6, and the supporting roller 6 is set and fixed on the lower cutter shaft 5. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com