Automation alternative production method of cold cathode fluorescent lamp

A technology of cold-cathode fluorescent lamps and production methods, which is applied to machines with sequentially arranged working positions, etc., which can solve the problems of unsatisfactory scale production, lower product quality, and troublesome problems, and achieve the effect of avoiding high product damage rate and realizing production automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

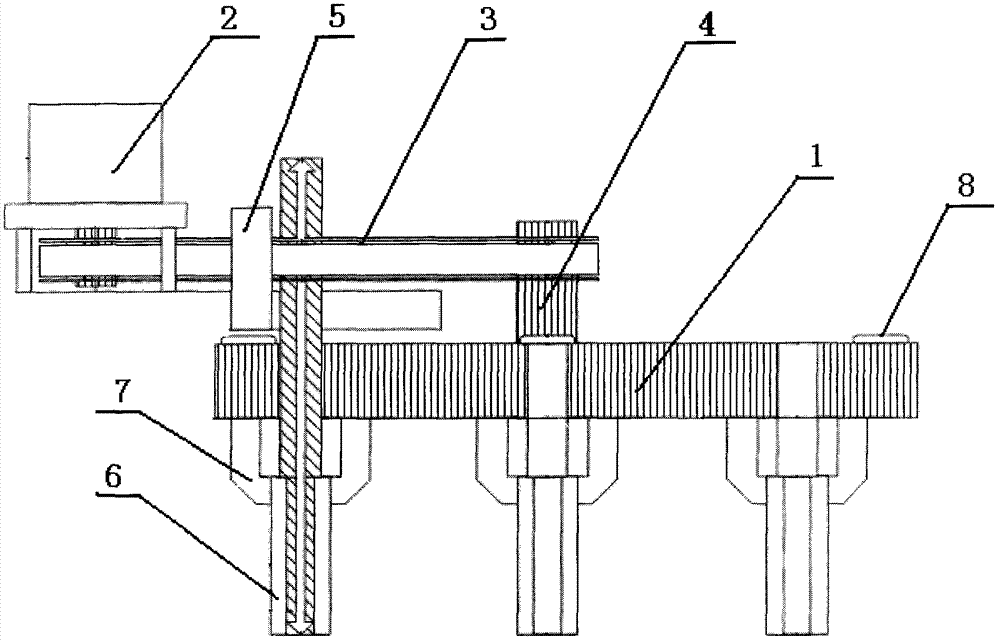

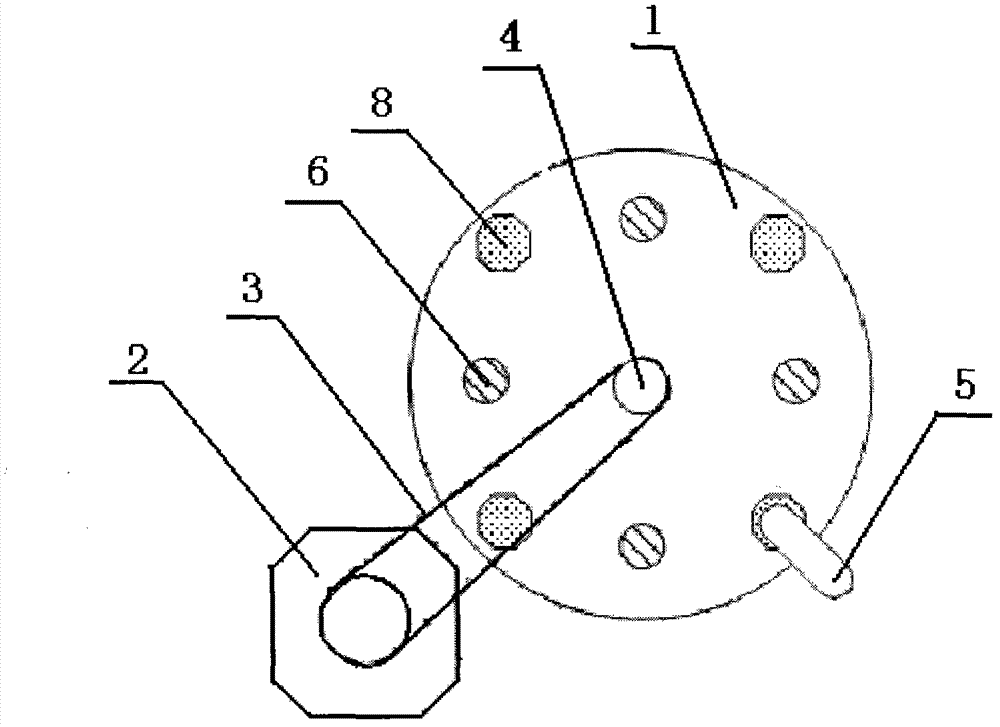

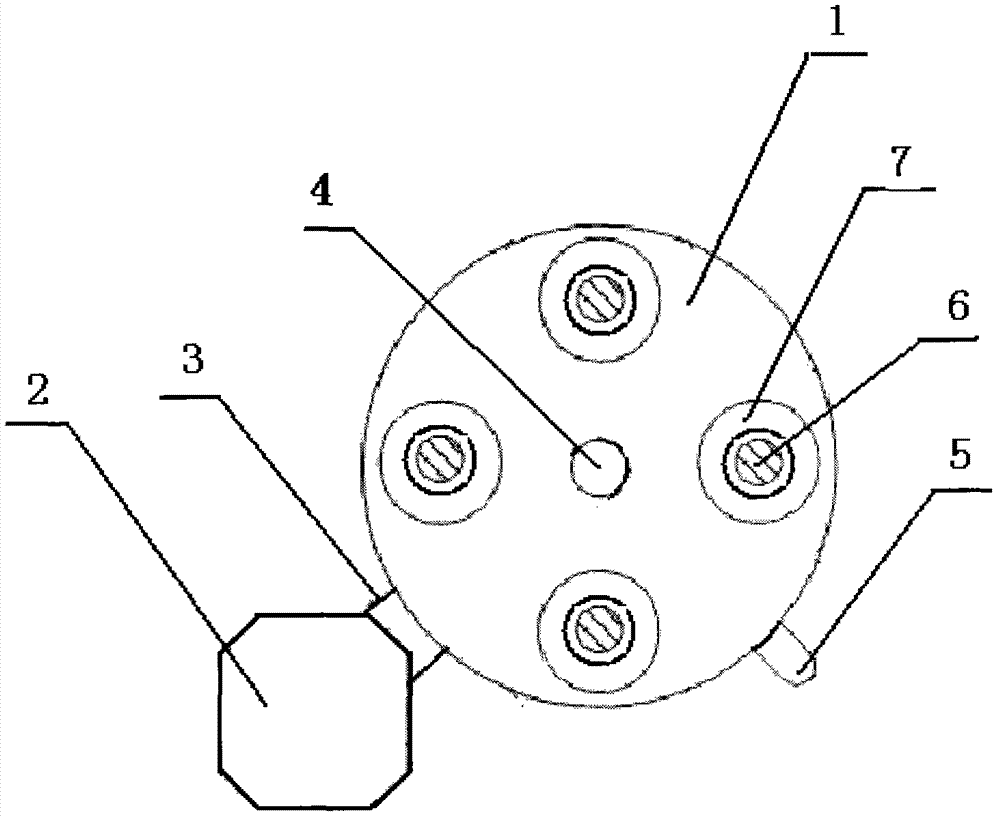

[0009] With reference to accompanying drawing, the present invention is realized like this: be provided with central shaft 4 on the rotary chuck 1, and be connected with motor 2 by transmission belt 3, be evenly distributed with 4 sealing resin clamps 7 on the rotary chuck 1, sealing resin The fixture 7 matches the lamp tube 6 of the same or different type, and the sealing resin fixture 7 can be replaced by tightening the switch 8. After the production line is started, the motor 2 is started to drive the rotary chuck 1 to rotate, so that the corresponding type of sealing resin fixture 7 Matching with the assembly line has completed the automatic alternate production method of the invention.

[0010] Through the invention, in the process of mass production of cold cathode fluorescent lamps, due to the change of product model, the automatic alternation of manufacturing process can be realized, thereby reducing the breakage rate of products, saving production cost and improving pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com