Electric type handling trolley for construction site

A technology for construction sites and handling trolleys, which is applied to motor vehicles, trolleys, multi-axis trolleys, etc. It can solve problems such as difficult to fix and prevent, difficult to switch operation modes, and not easy to use, etc., to achieve convenient transportation process, convenient adjustment, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

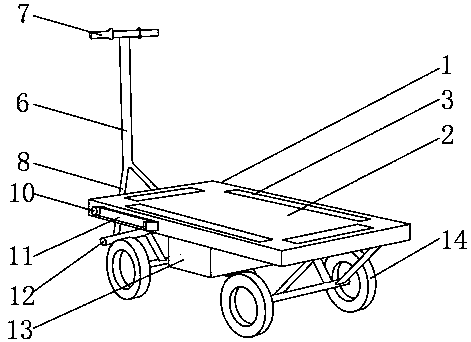

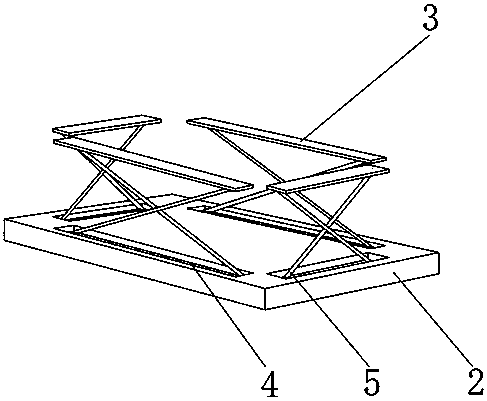

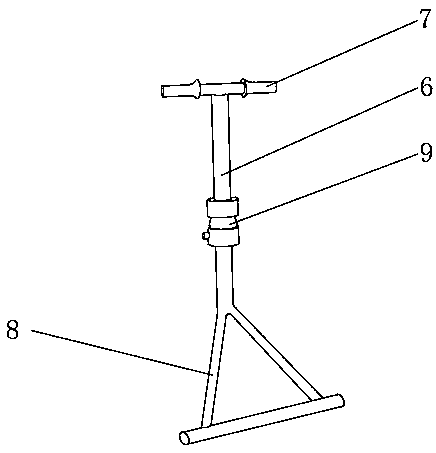

[0019] like Figure 1-3 As shown in the figure, an electric transport trolley for construction sites includes a truck main body 1, a truck flat 2 is fixedly installed on the upper outer surface of the truck main body 1, and a movable baffle 3 is arranged on the periphery of the upper outer surface of the truck flat 2 , while moving the material, the movable baffle 3 can be pulled up, so that the connecting inclined rod 5 inside the placement port 4 is raised, and the material placed on the outer surface of the upper end of the vehicle platform 2 can be protected to prevent the material from slipping during transportation. An installation port 4 is arranged below the movable baffle 3, and a connecting oblique rod 5 is fixedly installed between the installation port 4 and the movable baffle 3, and a control rod 6 is fixedly installed at one end of the vehicle plate 2, and the top of the control rod 6 is two The side outer surfaces are provided with moving handles 7, the bottom e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com