Blown film winding device in automatic correction

A winding device and automatic deviation correction technology, which is applied in the direction of winding strips, transportation and packaging, thin material processing, etc., can solve the problems of uneven winding deflection, waste, etc., and achieve neat and smooth blown film winding. The effect of cost reduction and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

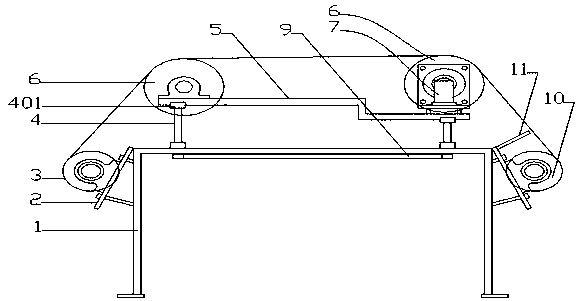

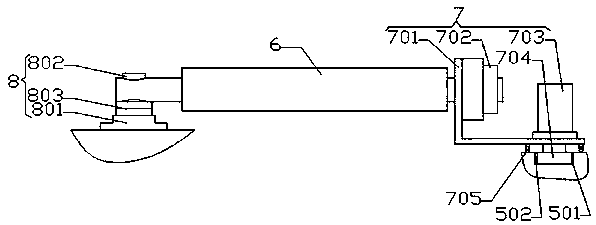

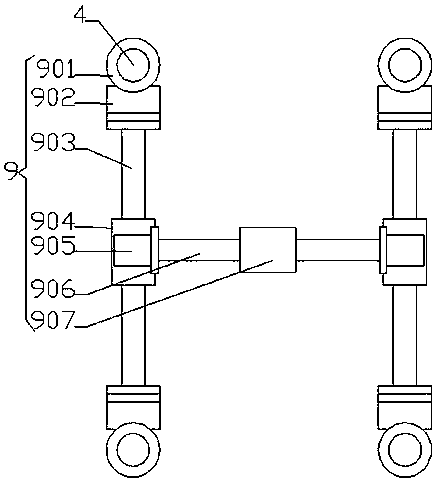

[0018] Such as Figure 1-3 As shown in , a blown film winding device with automatic deviation correction includes a frame 1, the frame 1 is an arched structure, and inclined side plates 2 are installed symmetrically on both sides, and one side plate passes through a bearing seat Connect the film-in roller 3, and the film-out roller 10 is connected on the other side plate through the bearing seat, the screw rod 4 is movably connected on the frame 1, the upper end of the screw rod 4 is connected to the lower plane of the balance board 5 through the bearing 401, and the left side of the balance board 5 passes through The bearing connects the leading film roller 6, and the correcting roller 6 is installed on its right side.

[0019] As a further improvement to the above solution, a deflection correction photoelectric sensor probe 11 is also arranged on the side plate 2 wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com