Sound-insulation and noise-reduction protective cover and mounting method

A protective cover and noise reduction technology, applied in the field of noise reduction, can solve problems such as noise pollution of power equipment, and achieve the effects of good safety, noise reduction, and easy water conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

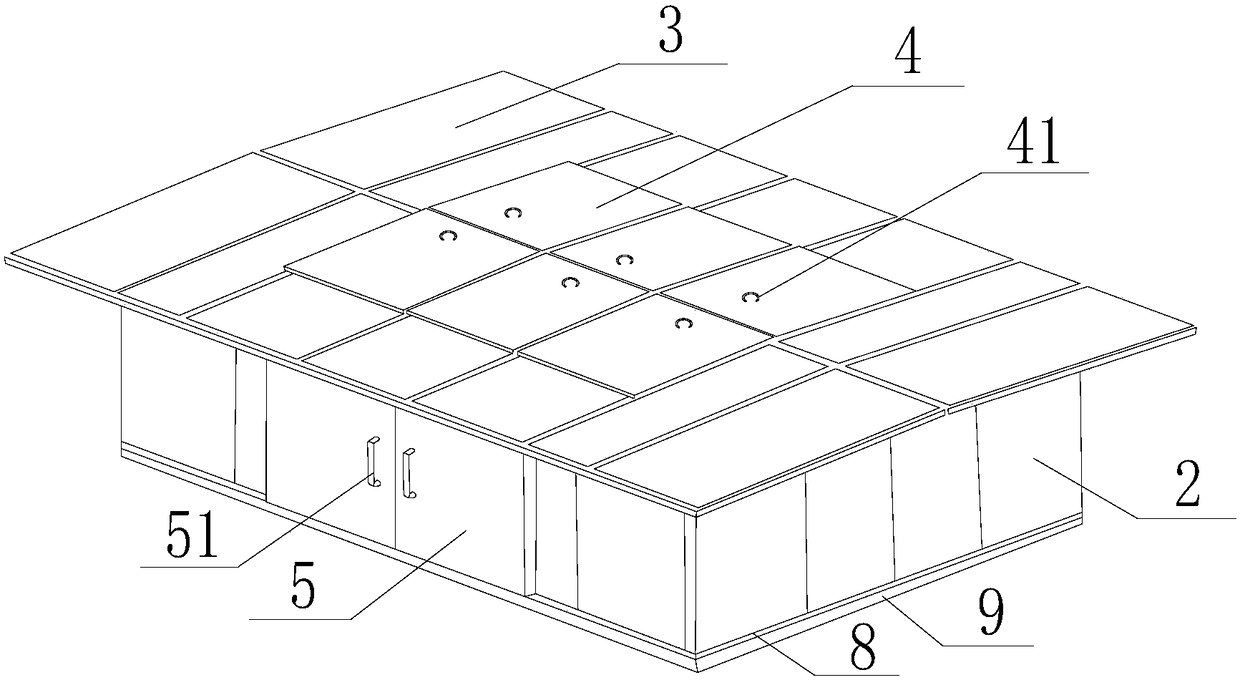

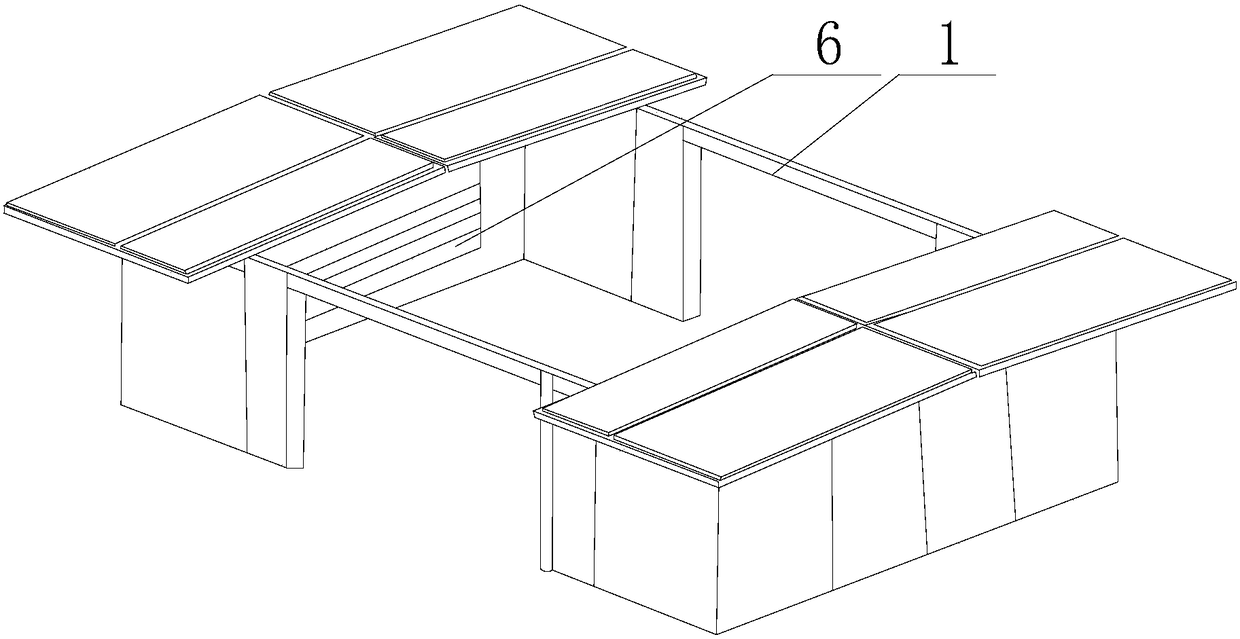

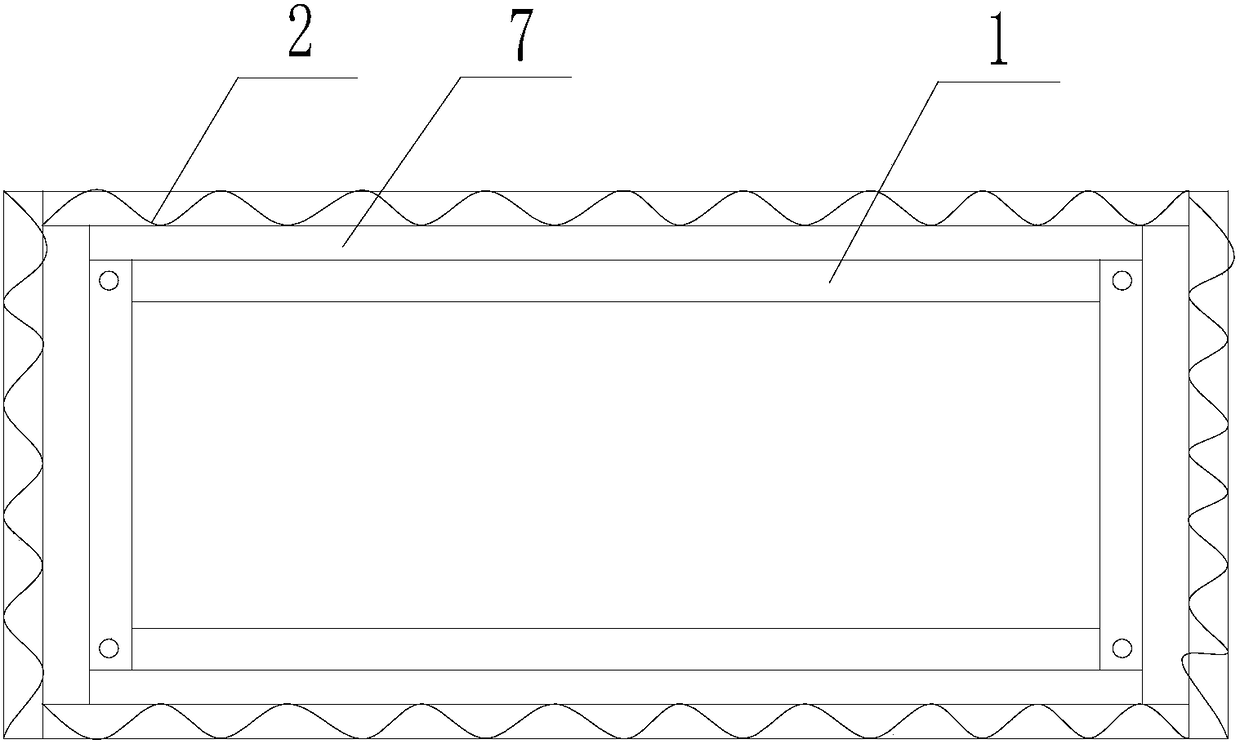

[0063] Such as Figure 1 to Figure 3 As shown, a sound insulation and noise reduction protective cover includes a steel frame 1, and the steel frame 1 is provided with a front side noise reduction mechanism, a rear side noise reduction mechanism, a left side noise reduction mechanism, a right side noise reduction mechanism and The top noise reduction mechanism, the front side noise reduction mechanism, the rear side noise reduction mechanism, the left side noise reduction mechanism, and the right side noise reduction mechanism are spliced by a plurality of vertical sound insulation panels 2, wherein the front side noise reduction mechanism, At least one of the rear noise reduction mechanisms is provided with a fire-proof and sound-proof door 5, the left noise reduction mechanism or the right noise reduction mechanism is provided with noise reduction shutters 6, and the top noise reduction mechanism includes horizontal sound insulation doors arranged at both ends. Board 3 and...

Embodiment 2

[0065] Such as Figure 1 to Figure 3 As shown, this embodiment is based on Embodiment 1. The horizontal sound insulation panels 3 and the open-hanging sound insulation panels 4 are symmetrically arranged in two rows. The open-hanging sound insulation panels 4 include a horizontal part and an inclined part, and one end of the inclined part It is hinged with the horizontal part, and the other end is spliced with another symmetrical inclined part; the inclined part is provided with lifting lugs 41; the four edges of the top noise reduction mechanism protrude from the front side noise reduction mechanism and the rear side noise reduction mechanism. mechanism, the left side noise reduction mechanism and the right side noise reduction mechanism; the fireproof soundproof door 5 is a sliding door structure, and the fireproof soundproof door 5 is provided with a handle 51.

Embodiment 3

[0067] Such as Figure 1 to Figure 3 As shown, this embodiment is based on Embodiment 1 or Embodiment 2, and also includes a circle of water retaining bricks 9, the water retaining bricks 9 enclose a rectangular frame structure, and the lower end of the steel frame 1 is connected to the water retaining bricks by expansion screws. Bricks 9 are connected, and the water-retaining bricks 9 are fixedly connected to the ground; a rubber plate 8 is arranged on the outer side of the lower end of the steel frame 1, and the thickness of the rubber plate 8 is 10 mm, and the width is 80 mm. Foam rubber strips are arranged between the steel frame 1; the steel frame 1 is made of galvanized steel sheet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com