Roadway excavation method for underground layered fractured rock mass of metal deposit

A technology for cracked rock mass and underground layers, applied in tunnels, mining equipment, earthwork drilling and mining, etc., can solve problems such as high roadway cost and high economic pressure in mines, and achieve the effect of improving roadway stability and safety production conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In the embodiment of the present invention, the RG downhole TV monitoring system is used to collect image information of the hole wall.

[0022] The roadway excavation method of the underground layered fissure rock mass of the metal ore deposit in the embodiment is carried out according to the following steps:

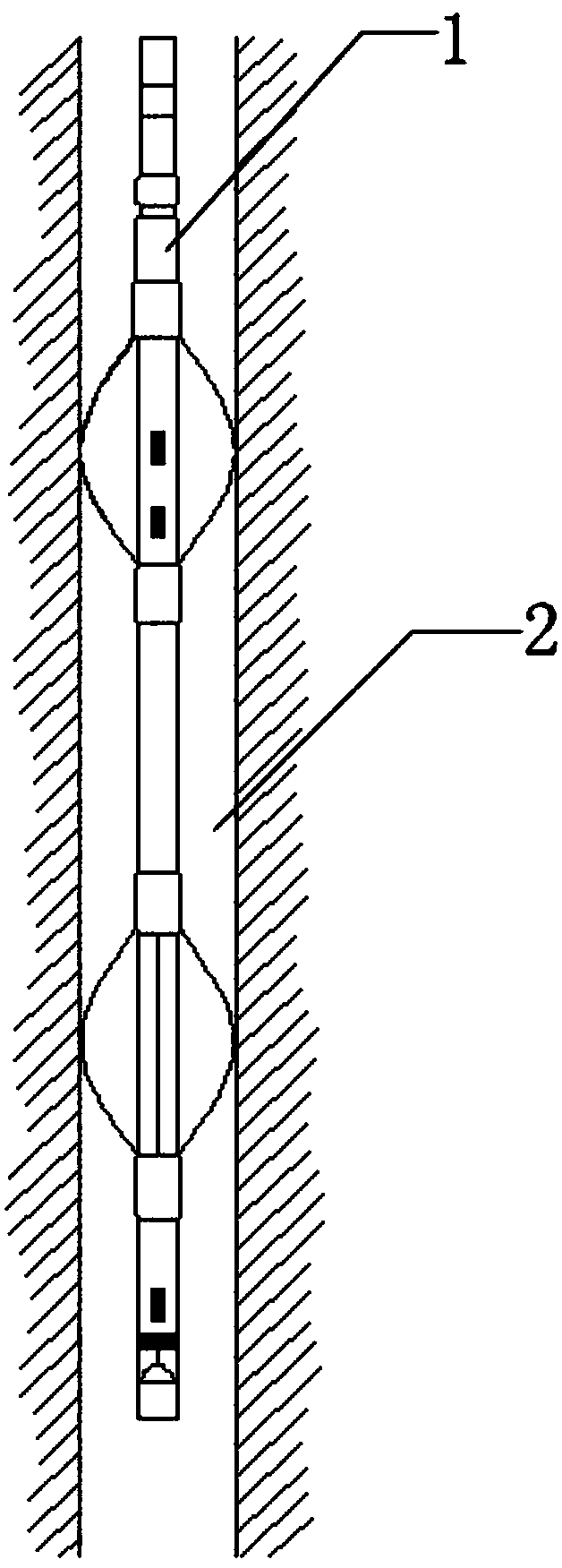

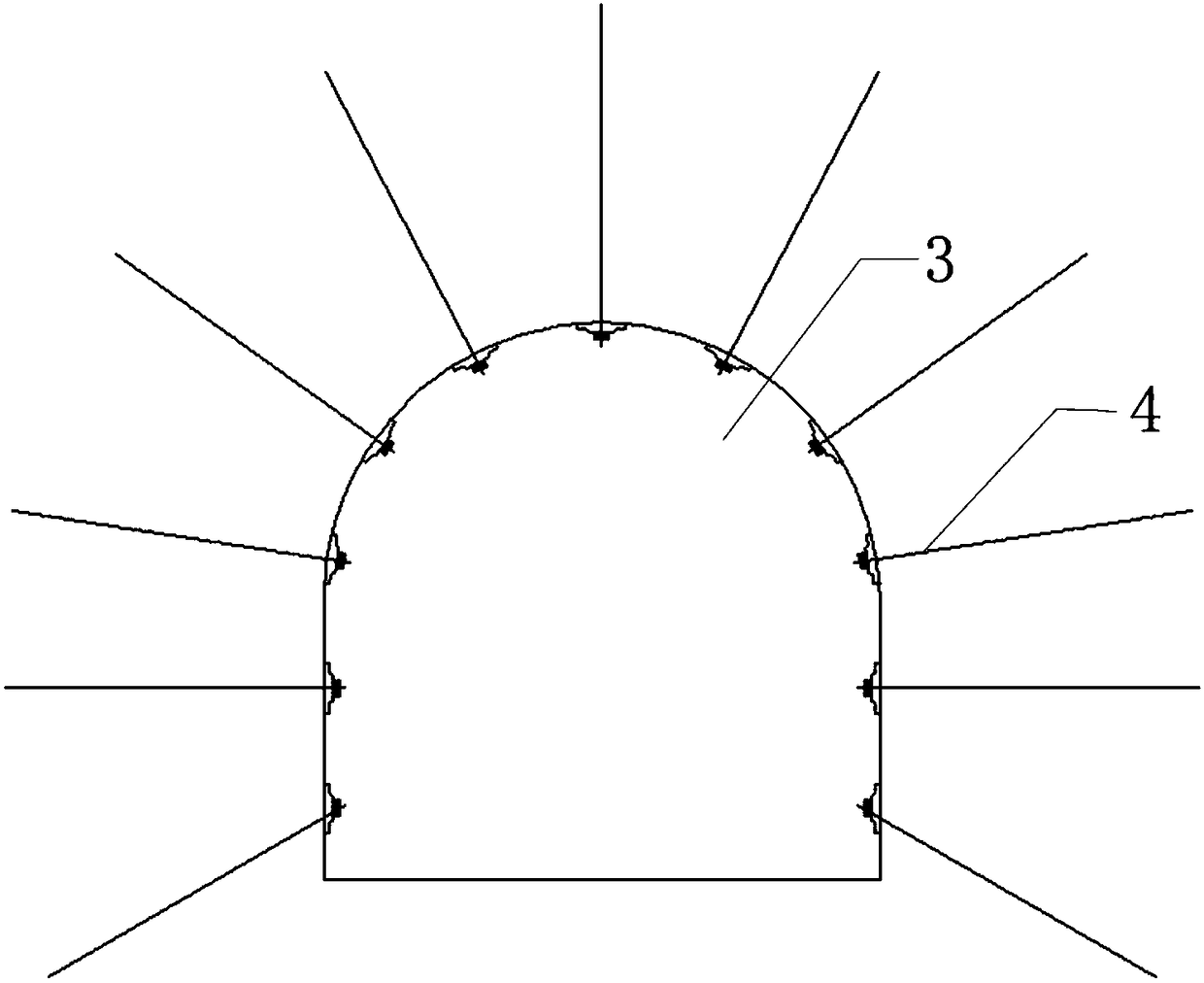

[0023] (1) In this embodiment, the underground iron mine in the Gongchangling section is taken as an example for illustration. In the underground roadway of the metal deposit that has been excavated, a section of Φ90 to Φ120 mm is drilled from the upper section of -280+36m to the lower section of the roadway. Measuring holes such as figure 1 As shown, the borehole camera device is used to collect the image information of the measurement hole wall, as shown in figure 2 As shown, according to the image information of the hole wall, the thickness of the cracked layer of the surrounding rock of the roadway is determined to be 0.1-0.8m, and the thickness of the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com