Cover system for tubular container housing

A shell and tube-shaped technology, applied in the field of cover systems of anti-backflow blocker shells, can solve the problems of the cover and the shell being underwater, difficult, etc., to reduce movement and inclination, prevent peeling force, simple and reliable The effect of rotatable anchors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

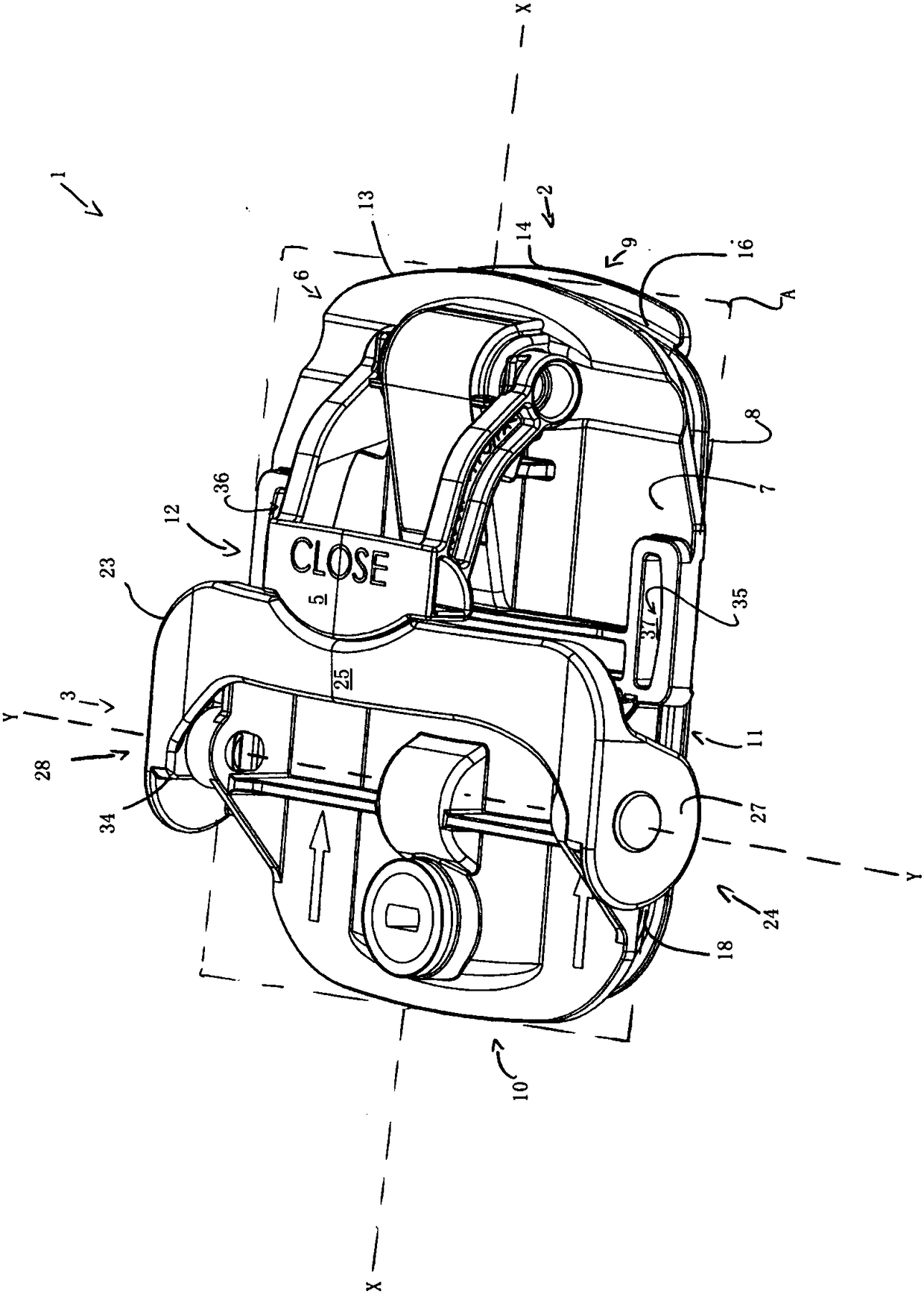

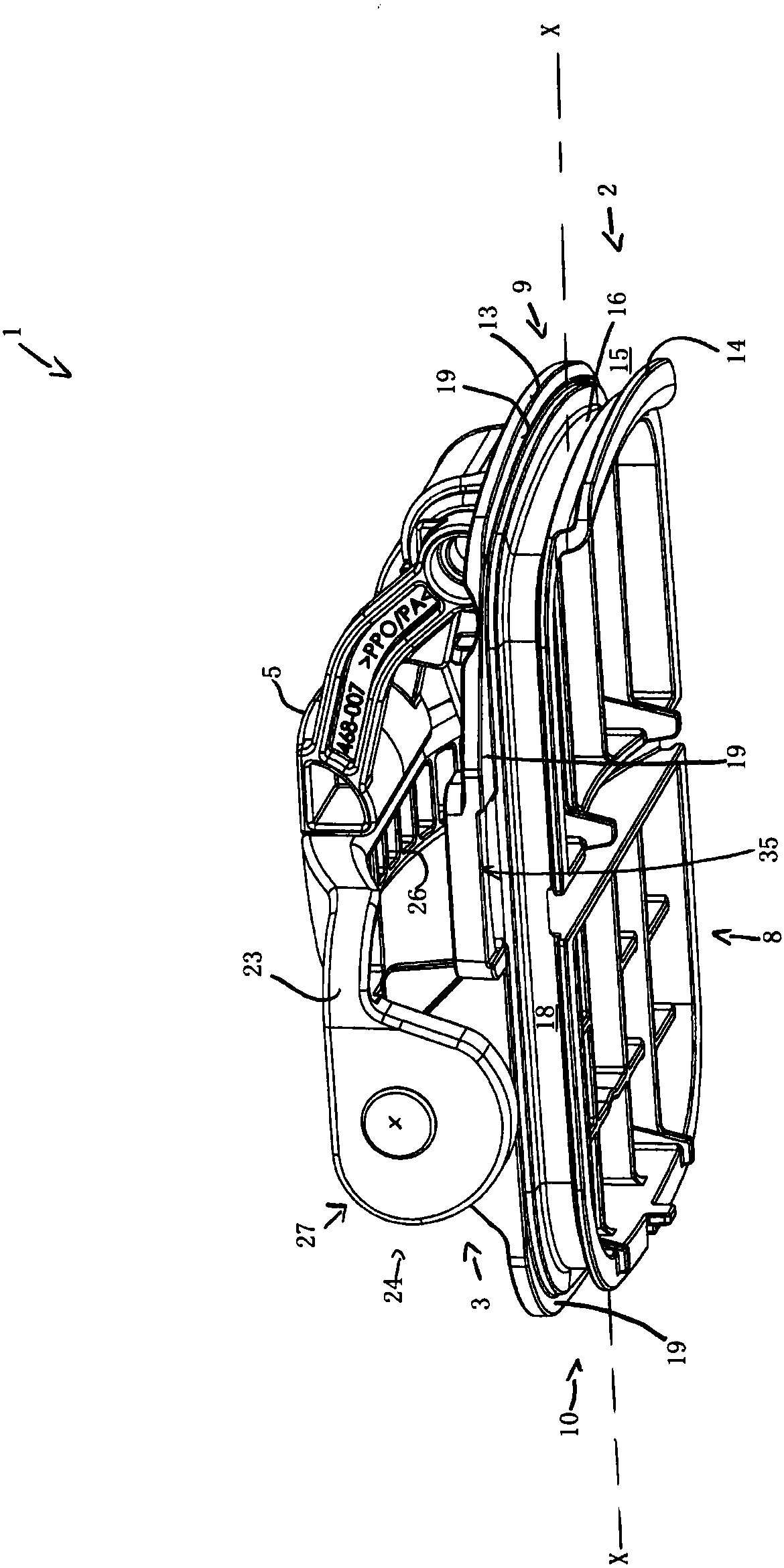

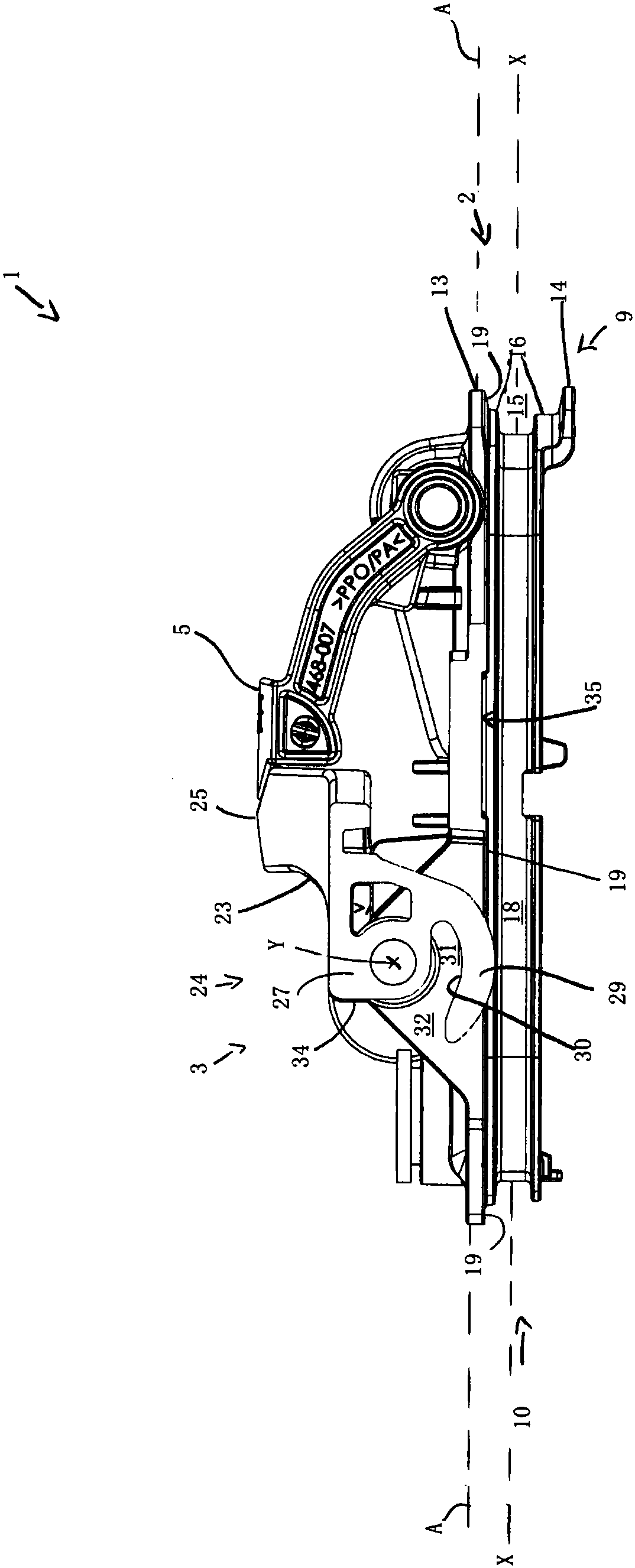

[0055] as in figure 1 As can be clearly seen in FIG. 1 , the cover system 1 comprises a cover 6 , a pivotal anchoring device 2 , a locking system 3 , two guide openings 35 , 36 and a regurgitation flap activation lever 5 .

[0056] The cover 6 is designed here approximately as a flat parallelepiped. The parallelepiped here has two parallel larger side walls, i.e. at figure 1 The upper surface 7 that can be seen in this figure and the lower surface 8 that is not visible in this figure and four narrower side walls, of which two opposite side walls 9, 10, (the side walls are parallel to each other) than the other two The opposite side walls 1, 12 are shorter, (the side walls are also parallel to each other). The main area of the cover 6 is located on the upper surface 7 and in the cover plane A. As shown in FIG. The two shorter side walls 9 , 10 extend along the longitudinal axis X of the cover 6 . below, figure 1 The shorter side wall 9 on the middle right is called the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com