Force balanced type plug and socket assembly

A technology of plug socket and plug assembly, which is applied in the direction of the base/housing, two-part connection device, contact parts, etc., can solve the problems of high production cost, poor use effect, and higher and higher requirements for socket safety, and achieve The effect of simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

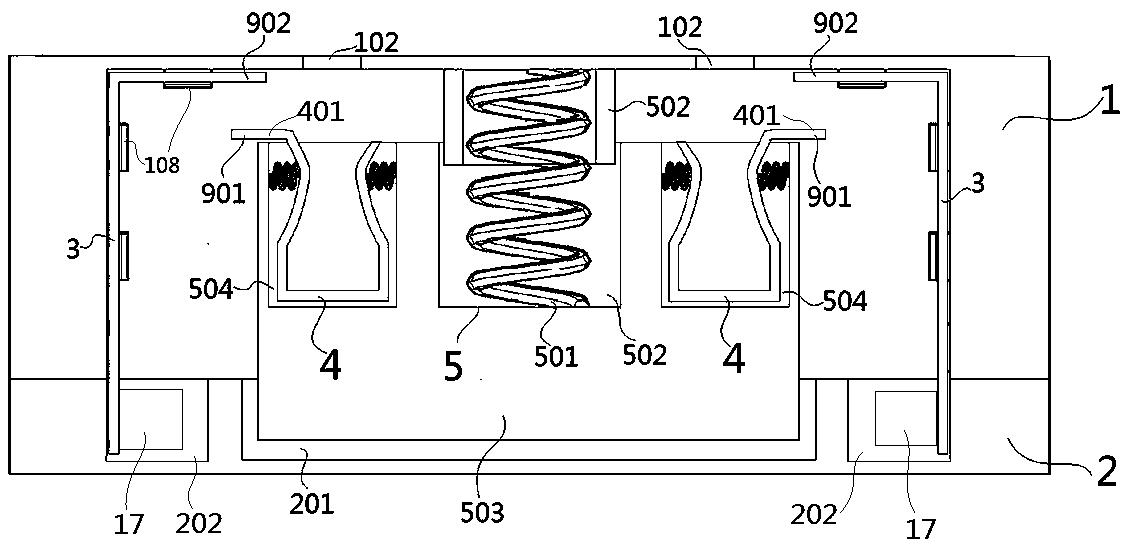

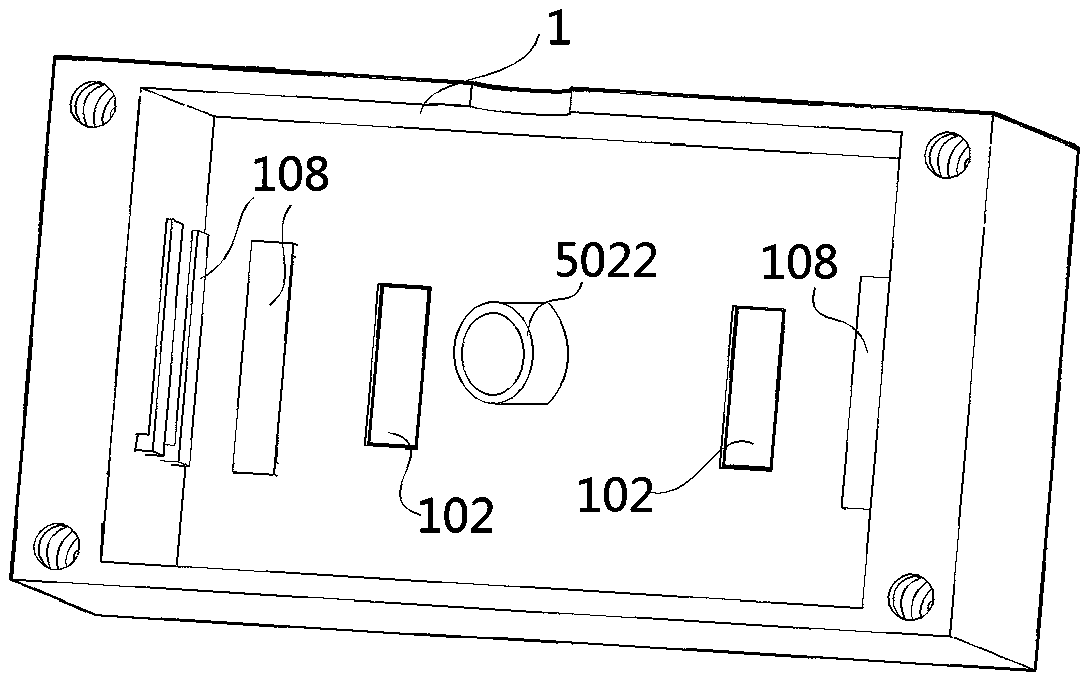

[0078] Such as Figure 1-4 As shown, a force-balanced plug and socket assembly of this embodiment includes a plug assembly and a socket assembly; the socket assembly includes a socket upper shell (1), a socket lower shell (2), and conductive tabs (3 ), socket body (4), first elastic device (5), socket side locking device (7) and switch (9).

[0079] The switch (9) includes a switch control part (901) and a switch fixing part (902); the inner wall of the socket upper shell (1) has a slot (108) for fixing the conductive lead piece (3); The lead piece (3) is fixedly installed in the card slot (108), and one end of the conductive lead piece (3) is led to the vicinity of the socket (102) to form a switch fixing part (902), and the other end can be connected to a terminal or a direct connection wire cable. The first elastic device (5) includes an elastic element (501), an insulating housing (502) and a base (503); the first elastic device (5) is installed inside the socket and can...

Embodiment 2

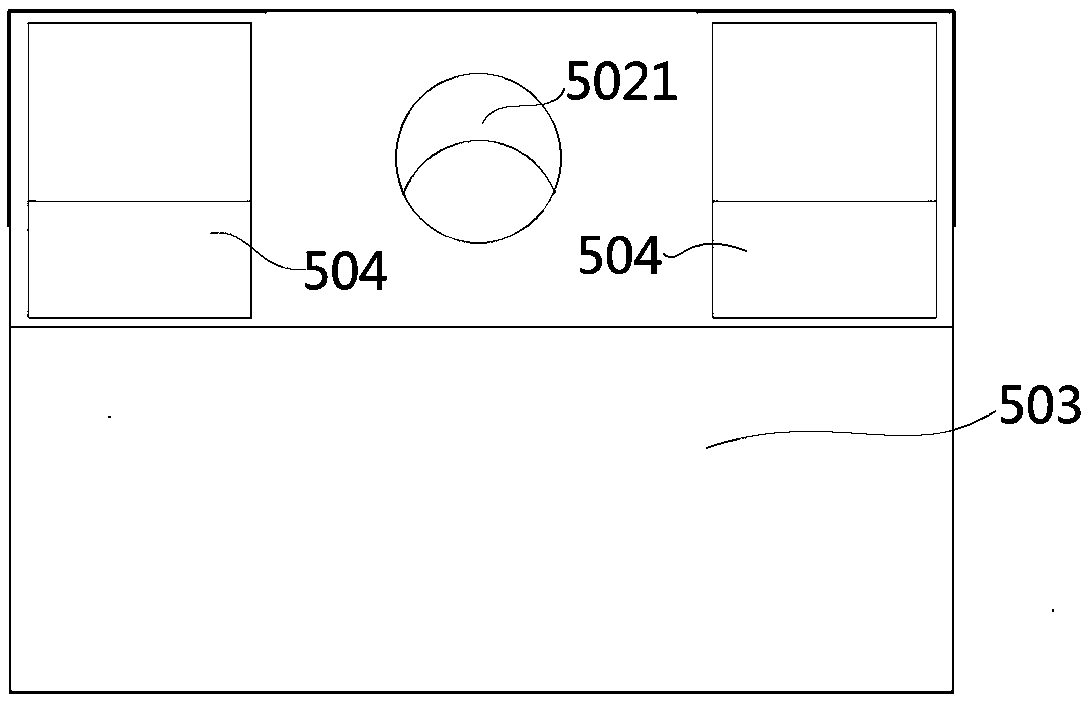

[0086] Such as Figure 5 As shown, a force-balanced plug and socket assembly in this embodiment includes a plug assembly and a socket assembly; the main structure of the socket assembly is basically the same as that in Embodiment 1, except that the base (503 ) on the socket body mounting position (504) is a plane, the plane may have a card slot or threaded hole structure, the socket body (4) can be fixedly installed on the socket body mounting position by screws or clamping (504) plane.

[0087] A socket assembly of this embodiment can cooperate with any of the plug assemblies described in Embodiments 21, 22, and 23 to form a plug and socket assembly, and the locking device and the elastic device respectively located on the plug and the socket cooperate to control the switch The movement thus controls the on-off of the line.

Embodiment 3

[0089] Such as Figure 6 As shown, a force-balanced plug and socket assembly of this embodiment includes a plug assembly and a socket assembly; the main structure of the socket assembly is basically the same as that of Embodiment 1, except that the socket upper shell ( 1) There is an inward groove (104) on the upper surface, and the area of the groove (104) is adapted to the area of the plug end or the second elastic device (6), so that when the plug is inserted into the socket, the elastic force generated by the elastic device The part exposed when the pin (16) is bounced is located in the groove (104), thereby preventing the occurrence of electric shock accidents.

[0090] A socket assembly of this embodiment can cooperate with any of the plug assemblies described in Embodiments 21, 22, and 23 to form a plug and socket assembly, and the locking device and the elastic device respectively located on the plug and the socket cooperate to control the switch The movement thus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com