Squid sorting device

A sorting device and squid technology, applied in fish sorting, processed fish, cephalopod processing, etc., can solve the problems of reducing processing effect, increasing the workload of personnel, reducing product quality, etc., to achieve convenient operation, Reasonable design and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

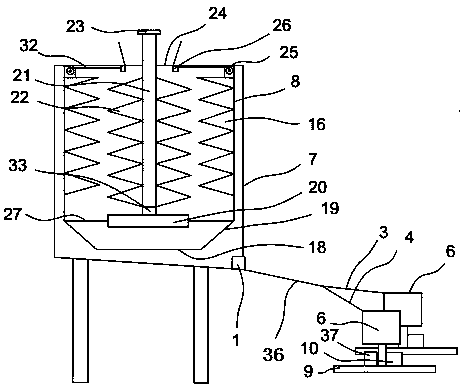

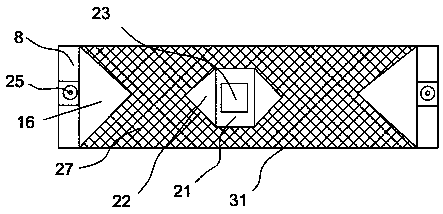

[0022] Such as Figure 1-7 Shown, the technical scheme that the present invention takes for realizing the above object is: squid sorting device, comprises mincing device 7, is provided with in the mincing device 7 the mincing case that is made up of movable plate 8 and fixed horizontal plate 31, so The upper end of the fixed horizontal plate 31 is connected to the inner upper end of the crushing device 7, and the upper end of the movable plate 8 is connected to the inner upper end of the crushing device 7 through a pulley 25. The inner upper end of the crushing device 7 is provided with a chute 32, and the pulley 25 can Sliding back and forth in the chute 32, the inner middle end of the crushing box is provided with a stirring rod 21, the stirring rod 21 is evenly distributed with twisted teeth 22, the inner side of the moving plate 8 is provided with fixed teeth 16, and the fixed teeth 16 and twisted teeth 22 are arranged in a staggered manner. By uniformly distributing the t...

Embodiment 2

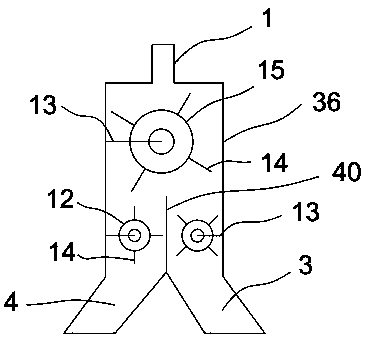

[0030] The working principle of the squid sorting device of the present invention is: start the motor 23, put the dissected squid into the crushing device 7 from the entrance 24, after the squid is crushed, slide down to the conveyor belt 36 through the discharge port 1 Above, the squids are sorted by the roller 15 and the second roller 12 and fall into the cylinder 6 from the outlet 3 and the second outlet 4 respectively, and slide down to the corresponding collection box 37 or collection box after being compared with the weight 17 10 collection, reach the purpose of squid secondary sorting.

[0031] The conventional technologies in the above embodiments are known to those skilled in the art, so they will not be described in detail here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com