A method for increasing the magnetic heat generation rate of calcium phosphate magnetic bone cement

A technology of bone cement and calcium phosphate, applied in tissue regeneration, medical science, prosthesis, etc., can solve the problems of increasing time cost and economic cost, complicated process engineering, high price, etc., and save time cost and economic cost, process Simple operation and short time-consuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

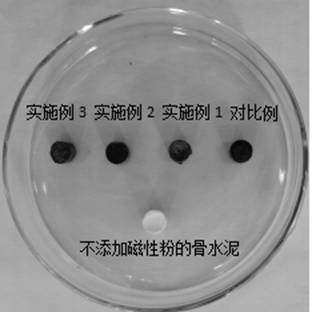

[0039] 2. Preparation of Magnetic Bone Cement

[0040] (1) Prepare a citric acid solution with a concentration of 0.5 mol / L as the liquid phase of the bone cement for later use;

[0041] (2) Weigh β-tricalcium phosphate and Ca(H 2 PO 4 ) 2 ·H 2 O powder, β-tricalcium phosphate and Ca(H 2 PO 4 ) 2 ·H 2 O powder is 200 mesh sieves, puts into the mortar and grinds for 15min, makes solid-phase phosphate powder, for subsequent use;

[0042] (3) Take the modified Fe prepared in step 1 (5) according to the weight ratio of 4:6 3 o 4 Put the magnetic functional phase and the solid-phase phosphate powder prepared in step 2 (2) into a mortar, grind for 15 minutes, and mix evenly to obtain a bone cement solid-phase mixture, which is set aside;

[0043] (4) Add the citric acid solution in step 2 (1) to the solid phase mixture prepared in step 2 (3) according to the ratio of 1 mL of bone cement liquid phase for every 3 g of bone cement solid phase mixture, and mix with a stainle...

Embodiment 1

[0046] A method for improving the magnetic heat generation rate of calcium phosphate magnetic bone cement, comprising the following steps:

[0047] 1. Fe 3 o 4 Magnetic functional phase and modified Fe 3 o 4 Preparation of Magnetic Functional Phase

[0048] Fe 3 o 4 by FeSO 4 and FeCl 3 The deionized aqueous solution is prepared by high-temperature reaction after adjusting the pH of the solution with sodium hydroxide solution, in which FeSO 4 , FeCl 3 1. The ratio of deionized water is: 335mg: 490mg: 8mL; the concentration of the sodium hydroxide solution is 2mol / L.

[0049] (1) The weighed FeSO 4 , FeCl 3 Dissolve in deionized water, stir until completely dissolved, set aside;

[0050] (2) Adjust the pH of the solution to 6.5 with sodium hydroxide solution, stir for 30 min, and set aside;

[0051] (3) Put the suspension in step 1 (2) into a hydrothermal reaction kettle, 160°C, 6h;

[0052] (4) Separation of the precipitate obtained in step 1 (3), washing with de...

Embodiment 2

[0060] A method for improving the magnetic heat generation rate of calcium phosphate magnetic bone cement, comprising the following steps:

[0061] 1. Fe 3 o 4 Magnetic functional phase and modified Fe 3 o 4 Preparation of Magnetic Functional Phase

[0062] Fe 3 o 4 by FeSO 4 and FeCl 3 The deionized aqueous solution is prepared by high-temperature reaction after adjusting the pH of the solution with sodium hydroxide solution, in which FeSO 4 , FeCl 3 1. The ratio of deionized water is: 330mg: 492mg: 8mL; the concentration of the sodium hydroxide solution is 2mol / L.

[0063] (1) The weighed FeSO 4 , FeCl 3 Dissolve in deionized water, stir until completely dissolved, set aside;

[0064] (2) Adjust the pH of the solution to 6.5 with sodium hydroxide solution, stir for 30 min, and set aside;

[0065] (3) Put the suspension in step 1 (2) into a hydrothermal reaction kettle, 160°C, 6h;

[0066] (4) Separation of the precipitate obtained in step 1 (3), washing with de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com