Robot manipulator control method, device and system

A technology of a control device and a control method, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems that autonomous operations are not stable and reliable, and the technical requirements of operators are high, so as to improve operation efficiency and safety, improve stability and reliability. Reliability and the effect of reducing secondary accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

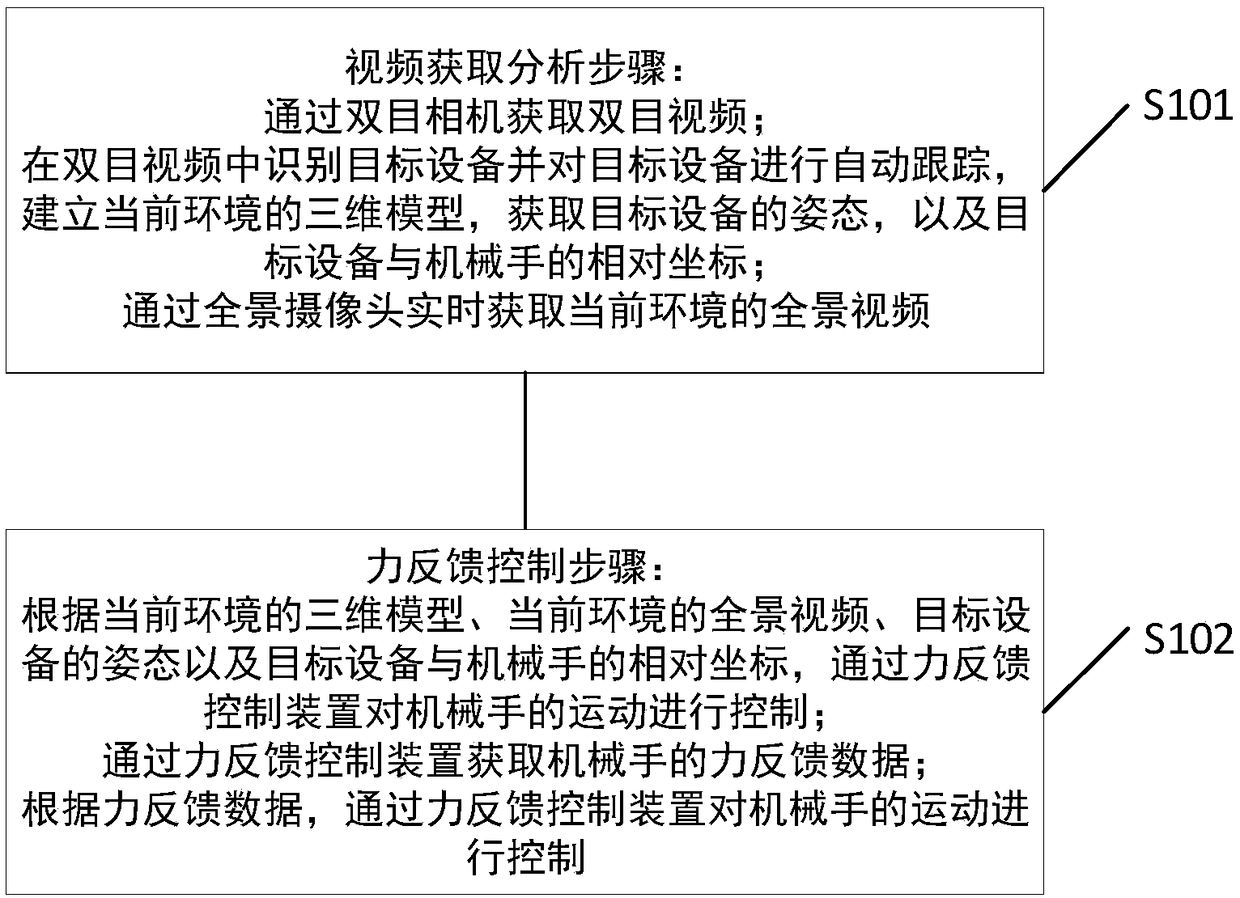

[0056] like figure 1 As shown, the embodiment of the present invention provides a robot manipulator control method, including:

[0057] Video acquisition and analysis step S101:

[0058] Obtain binocular video through binocular cameras;

[0059] Identify the target device in the binocular video and automatically track the target device, establish a 3D model of the current environment, obtain the posture of the target device, and the relative coordinates of the target device and the manipulator;

[0060] Get the panoramic video of the current environment in real time through the panoramic camera;

[0061] Force feedback control step S102:

[0062] According to the 3D model of the current environment, the panoramic video of the current environment, the attitude of the target device, and the relative coordinates between the target device and the manipulator, the movement of the manipulator is controlled through the force feedback control device;

[0063] Obtain the force feed...

specific Embodiment 2

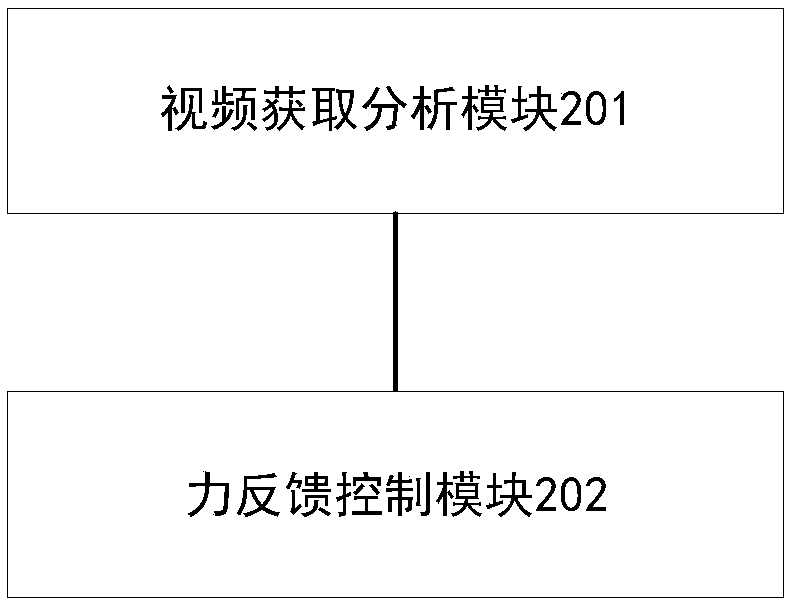

[0071] like figure 2 As shown, the embodiment of the present invention provides a robot manipulator control device, including:

[0072] The video acquisition analysis module 201 is used for:

[0073] Obtain binocular video through binocular cameras;

[0074] Identify the target device in the binocular video and automatically track the target device, establish a 3D model of the current environment, obtain the posture of the target device, and the relative coordinates of the target device and the manipulator;

[0075] Get the panoramic video of the current environment in real time through the panoramic camera;

[0076] The force feedback control module 202 is used for:

[0077] According to the 3D model of the current environment, the panoramic video of the current environment, the attitude of the target device, and the relative coordinates between the target device and the manipulator, the movement of the manipulator is controlled through the force feedback control device; ...

specific Embodiment 3

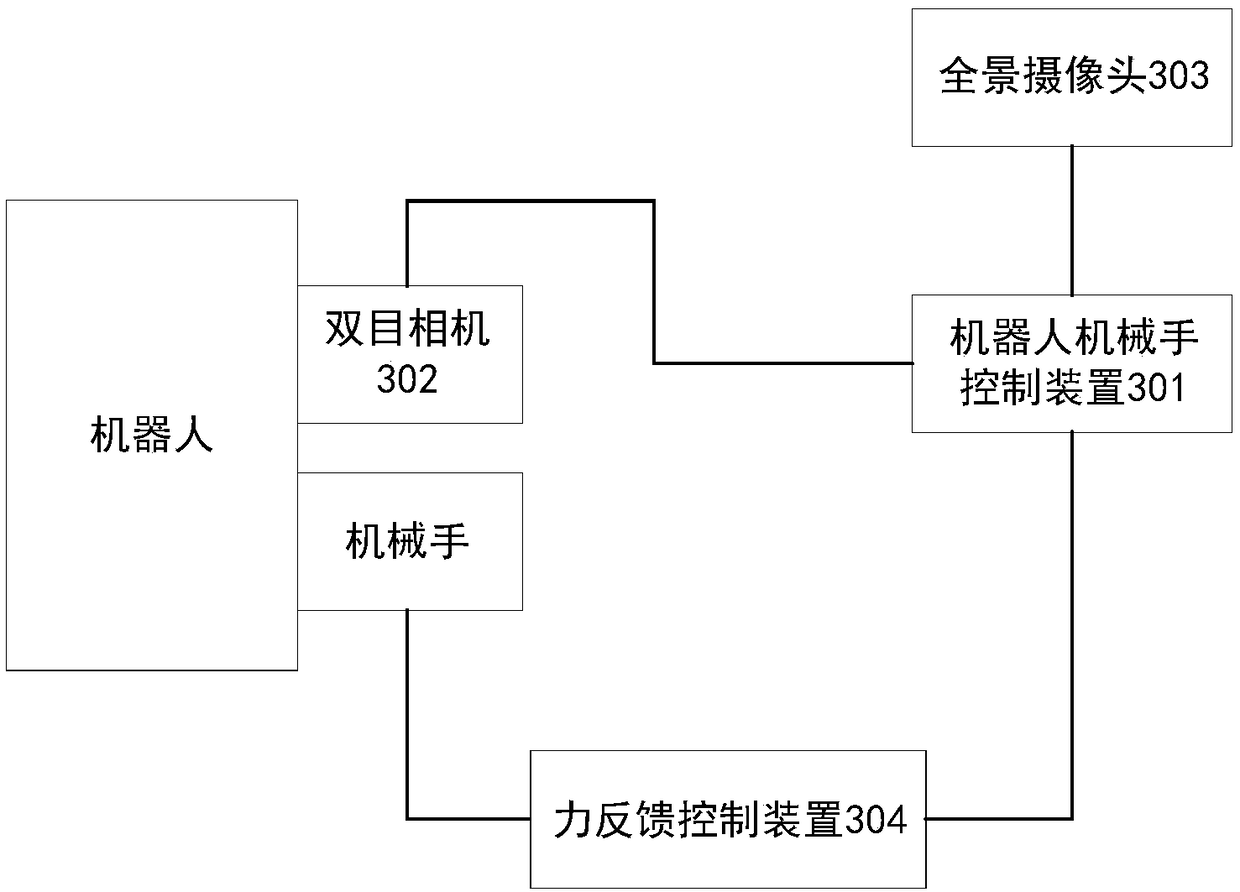

[0082] like image 3 As shown, the embodiment of the present invention provides a robot manipulator control system, including:

[0083] The robot manipulator control device 301 in the second specific embodiment;

[0084] binocular camera 302, for obtaining binocular video;

[0085] Panoramic camera 303, for real-time acquisition of panoramic video of the current environment;

[0086] The force feedback control device 304 is used to acquire force feedback data of the manipulator and control the movement of the manipulator.

[0087] The binocular camera 302 can be installed on the robot; the panoramic camera 303 can be fixedly installed at a certain position in the current environment; the force feedback control device 304 can be installed on the robot.

[0088] preferred, such as Figure 4 As shown, the force feedback control device 304 may include an online manipulator force detection module, a communication module, a manual operation module and an offline force feedback r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com