Solar ship water touch surface direct-current pulse magnetic current propulsion system

A DC pulse and propulsion system technology, applied in the field of ship power, can solve problems such as resistance on the surface of the hull, turbulent flow caused by propellers, and energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

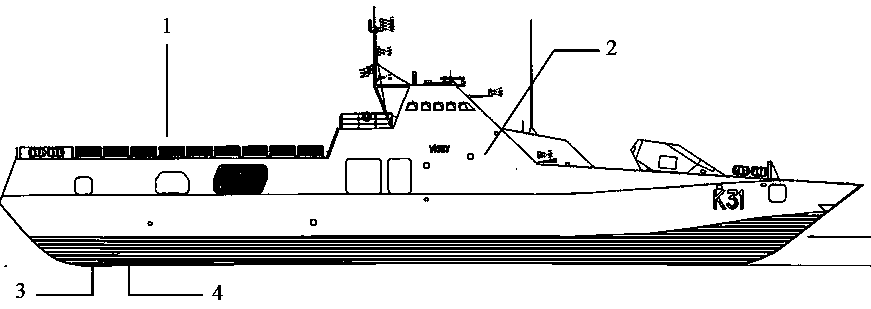

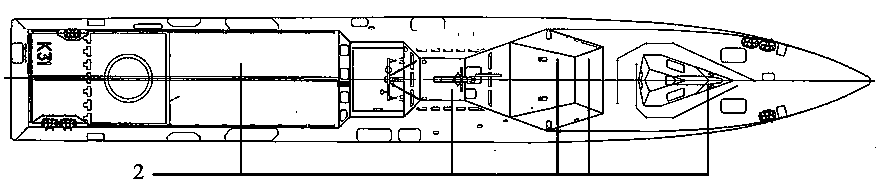

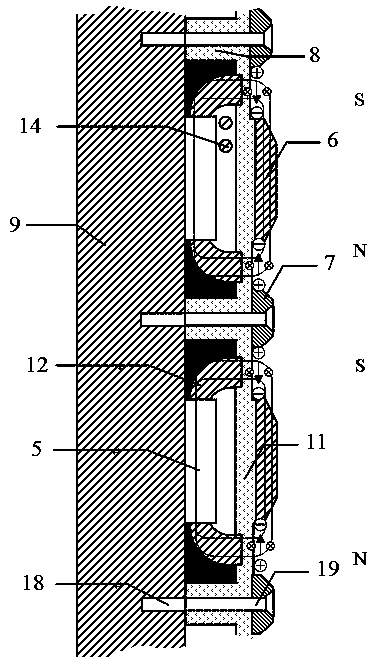

[0050] Embodiment 1: The present invention is fixed by solar cell panels (2), magnetic strips (3), water pushing grooves (4), magnetic field coils (5), electrode strips (6), dual electrode strips (7), and electrode strips The base (8), the electromagnetic nail fixing base plate (10), the electromagnetic nail (11), the power supply line (12), the electrode strip fixing bolt hole (13), the fixing bolt hole (14), and the control push rod (15);

[0051] The entire outer surface of the hull is laid with an electromagnetic nail fixing substrate (10) parallel to the moving direction, and the electromagnetic nail (11) is pasted and embedded on the inner groove of the electromagnetic nail fixing substrate (10) to form a magnetic strip (3), and the electromagnetic nail is fixed The substrate (10) is a non-electrical metal insulating anti-corrosion material, the electromagnetic nail (11) is set in the shape of "I", the central area is wound with a magnetic field coil (5), and the magnetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com