Solar ship water touch surface magnetic current propulsion system

A propulsion system and solar energy technology, applied in the field of ship power, can solve problems such as energy consumption, turbulent flow caused by propeller agitation, and resistance generated on the surface of the hull

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

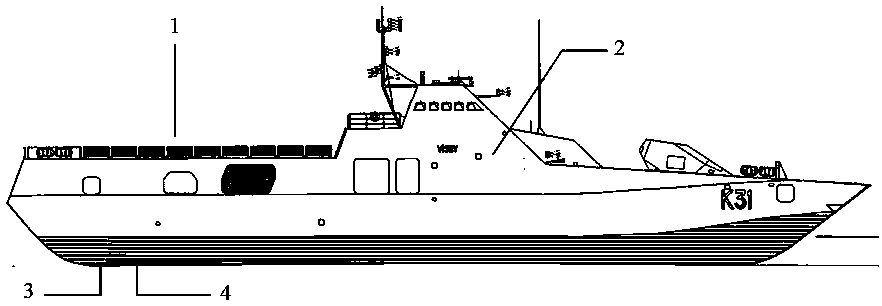

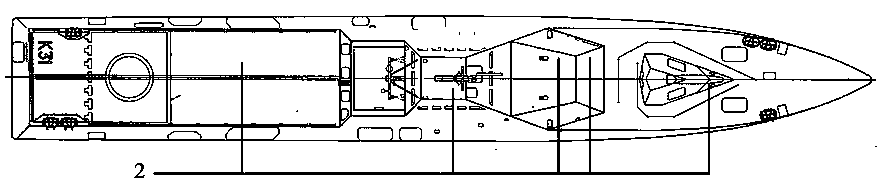

[0044] Embodiment 1: The section of the hull (1) is divided based on the center line, such as Figure 7 As shown, the surface of the hull (1) is divided into left and right sides, the magnetic current propulsion surface on the left side of the hull forms the left power zone, and the magnetic current propulsion surface on the right side of the hull forms the right power zone; each power zone is independently installed with an electric drive system, The structures of the two electric drive systems are exactly the same; after dividing the power area, when the hull turns, there is a difference in the water flow between the left power area of the magnetic current propulsion surface on the left surface of the hull and the right power area of the magnetic current propulsion surface on the right surface of the hull. The steering of the hull can be realized.

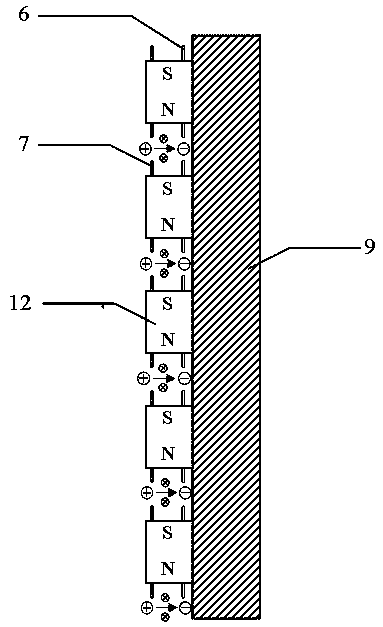

[0045] The entire outer surface of the hull is laid with a magnetic nail fixing base strip (11) parallel to the moving direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com