Mold pressing automatic discharge machine

A discharger and automatic technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of high operation complexity, low efficiency, unfavorable production, etc., to avoid damage, improve placement efficiency, and improve The effect of reprint yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

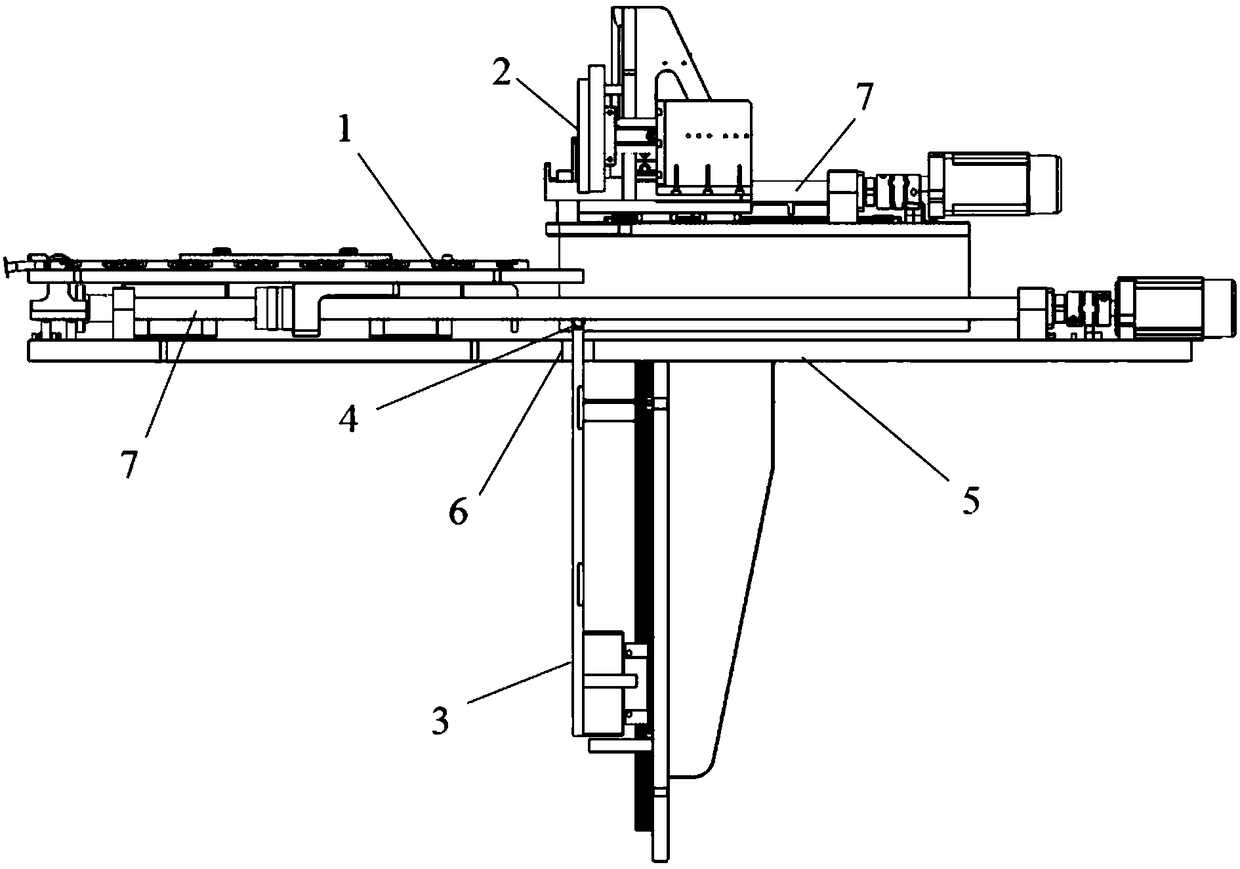

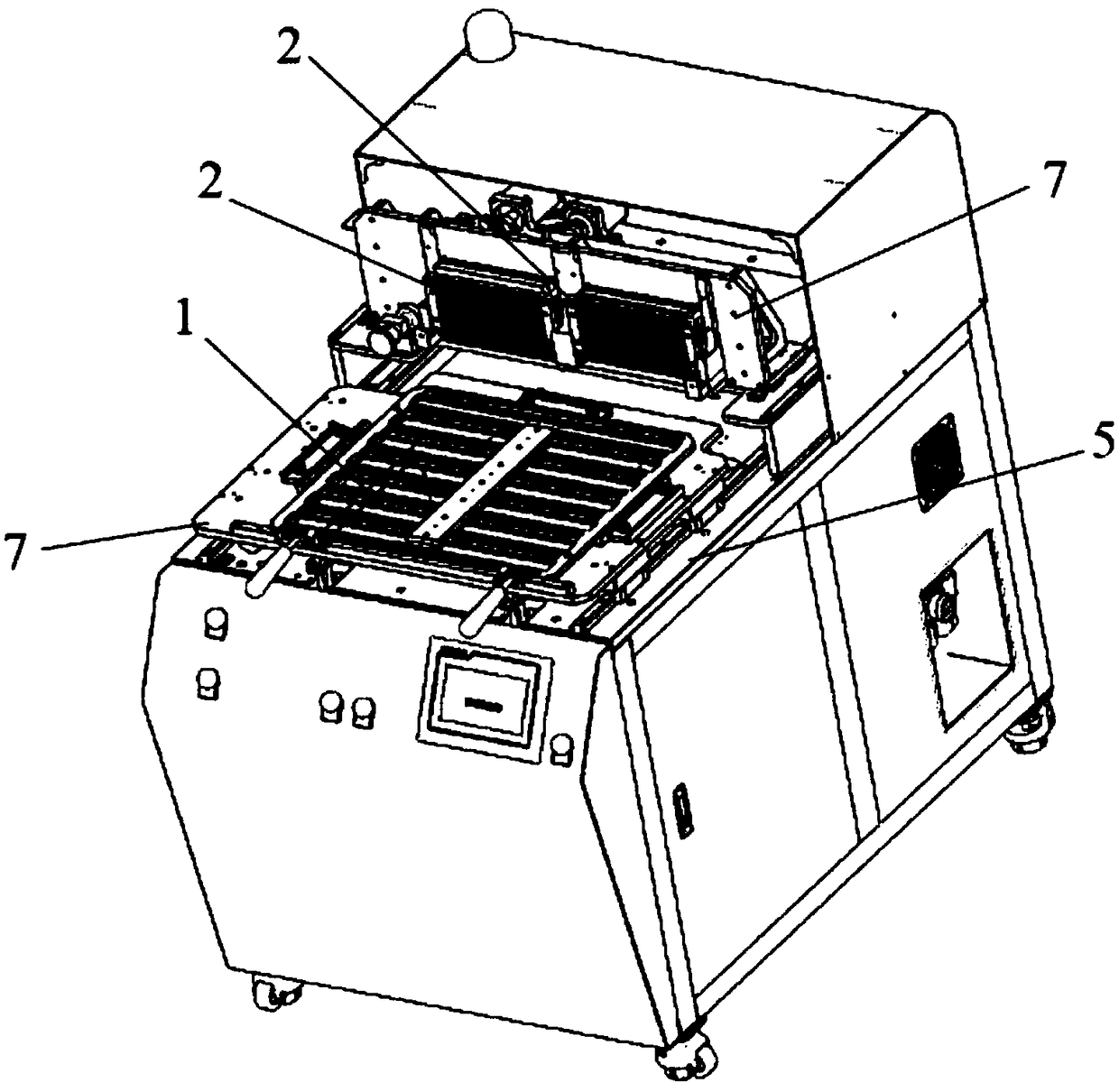

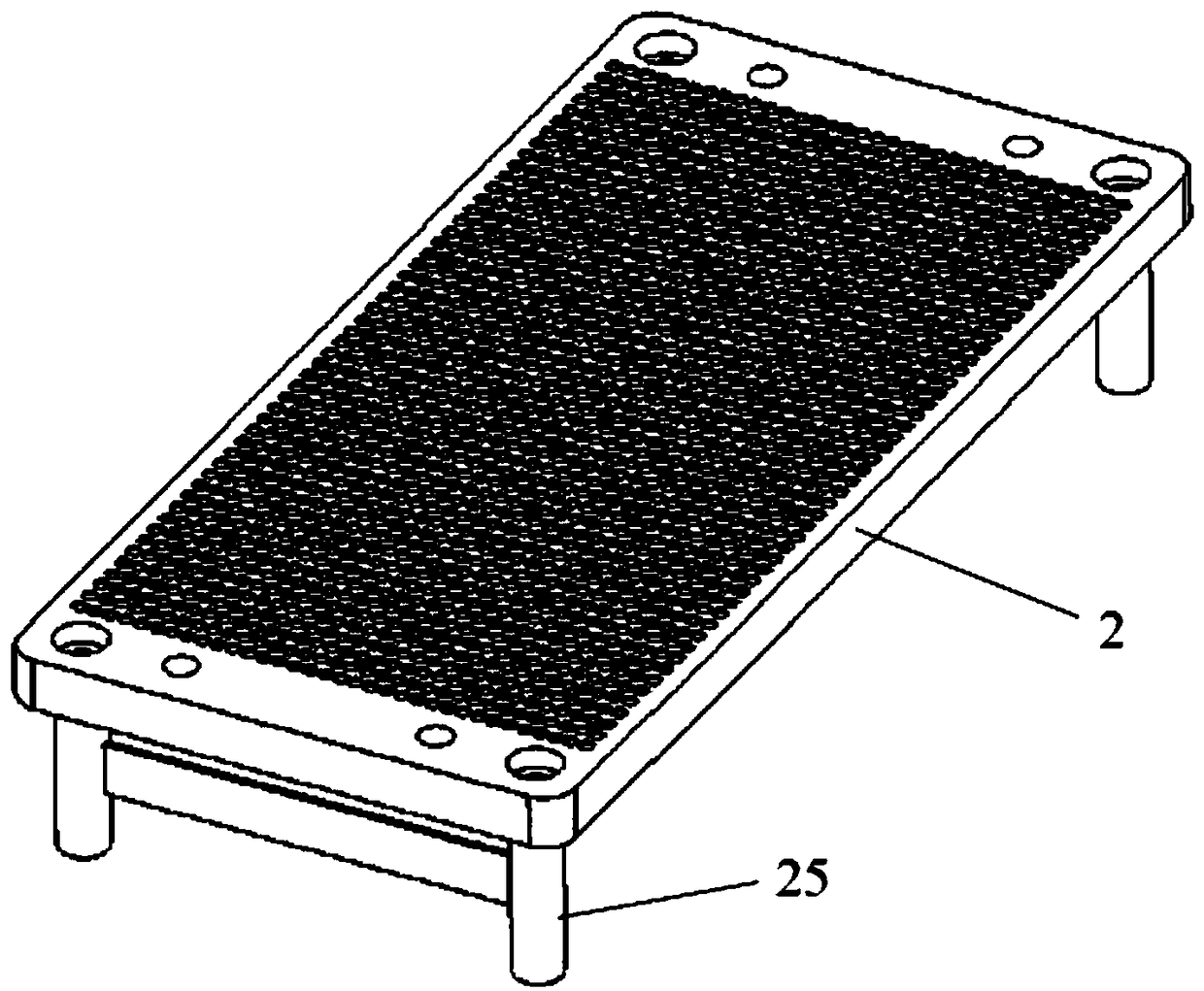

[0042] refer to figure 1 As shown, an embodiment of the molding automatic discharger of the present invention includes a carding table 1 and a diode carrier 2, the carding table and the diode carrier cooperate to form a reprint angle, and a reloading mechanism is arranged between the carding table and the diode carrier 3. The transfer mechanism is equipped with a combing table 4. After the carding table and the diode carrier cooperate to form a transfer angle, the transfer mechanism can drive the combing table to transfer the diodes on the diode carrier to the carding table in parallel for placement. Since the diode does not need to change its position, there is no need to clamp t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com