Deep sea flexible buoyancy force material and preparation method thereof

A buoyant material, deep-sea flexible technology, applied in the field of buoyancy materials, can solve problems such as water depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

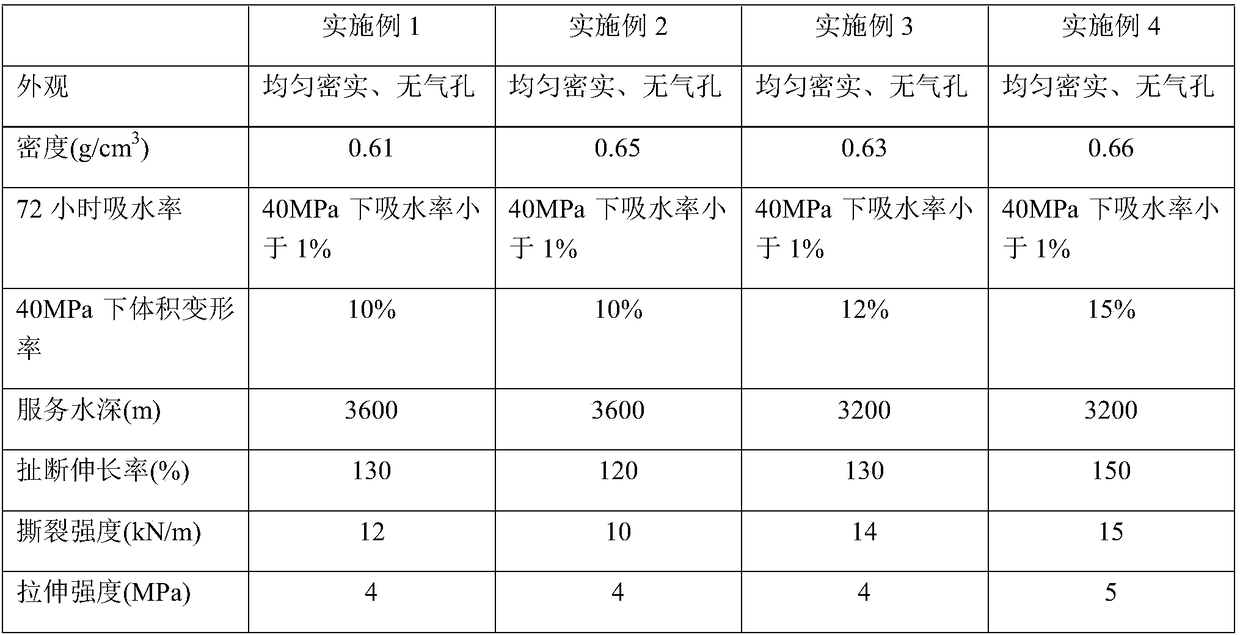

Examples

preparation example Construction

[0031] The present invention also provides a preparation method for the above-mentioned deep-sea flexible buoyancy material, comprising the following steps:

[0032] (1) hollow microspheres, liquid rubber, vulcanizing agent are mixed by the mass ratio of 100:(130-200):(0.2-3), after vacuum degassing, obtain compound;

[0033] (2) Inject the mixture into the mold and apply a pressure of 1-3MPa;

[0034] (3) The mixed material is vulcanized under the applied pressure to obtain the deep-sea flexible solid buoyancy material.

[0035] In this article, the term "vulcanizing agent" is sometimes also called curing agent, which refers to a substance that can make linear molecules bond and cross-link each other to form a network structure, including but not limited to sulfur. Further, according to the needs of vulcanization, during the vulcanization process, auxiliary agents such as accelerators and active agents can also be added. For example, it can be added in a ratio of hollow mic...

Embodiment 1

[0040] (1) Hollow glass microspheres (US 3M company, HGS8000X, density 0.42g / cm3 ) 2000g, liquid nitrile rubber (LNBR820, Shanghai Pinsheng Chemical Co., Ltd.) 2600g, sulfur 4g, tetramethylthiuram disulfide 50g and zinc oxide 40g (mass ratio is 100:130:0.2:2.5:2) machinery Stir to mix, then vacuum degass for later use.

[0041] (2) Put the above mixture into a mold and pressurize to 2MPa.

[0042] (3) Under the pressure of 2MPa, vulcanize according to the vulcanization process of 85°C for 30 minutes, then 115°C for 60 minutes, and finally 160°C for 120 minutes. After the vulcanization is completed, the vulcanized material is taken out from the mold to obtain the deep-sea flexible solid buoyancy material.

Embodiment 2

[0044] (1) Hollow glass microspheres (US 3M company, HGS8000X, density 0.42g / cm 3 ) 2000g, liquid silicone rubber (Shenzhen Hongyejie Technology Co., Ltd., 620A) 2600g, special curing agent (Shenzhen Hongyejie Technology Co., Ltd., 620B) (vulcanizing agent) 30g (mass ratio is 100:130:1.5) mechanical stirring Mixed and degassed under vacuum for later use.

[0045] (2) Put the above mixture into a mold and pressurize to 3MPa.

[0046] (3) Place it at room temperature under the above pressure for 10 hours to cure. After the curing is completed, the cured material is taken out from the mold to obtain the deep-sea flexible solid buoyancy material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com