High strength decorative material

A decorative material and high-strength technology, applied in the field of wood, can solve the problems of less research and application of glass fiber, which are rare, and achieve the effect of good waterproof and breathable performance, long service life, and conducive to popularization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

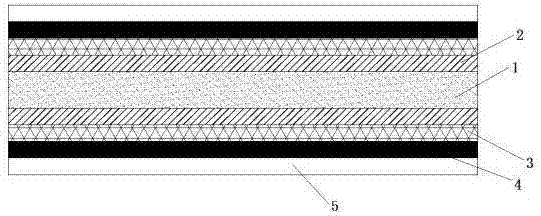

[0061] A high-strength decorative material is composed of a waterproof layer 5, an anti-oxidation layer 4, a reinforcement layer 3, a gas-permeable layer 2, a composite core board 1 arranged in sequence; the waterproof layer 5 is a polyurethane waterproof layer 5, and the anti-oxidation layer Layer 4 is a silicon carbide anti-oxidation layer 4, said reinforcing layer 3 is a carbon fiber layer arranged in a grid structure, and said breathable layer 2 is a 2:3 mixed layer of polyvinyl alcohol fiber and polypropylene fiber. The raw materials of the core board 1 and the weight parts of each raw material are:

[0062] The raw materials of the composite core board 11 and the weight parts of each raw material are:

[0063] Sandalwood powder: 27 parts;

[0064] Cizhu powder: 20 servings;

[0065] Non-alkaline chopped glass fiber: 15 parts;

[0066] Flax fiber: 6 parts;

[0067] 12 parts of animal bone meal;

[0068] Basalt fiber: 20 parts;

[0069] Methyl isothiazolinone: 19 parts;

[0070] 10 pa...

Embodiment 2

[0089] A high-strength decorative material is composed of a waterproof layer 5, an anti-oxidation layer 4, a reinforcement layer 3, a gas-permeable layer 2, a composite core board 1 arranged in sequence; the waterproof layer 5 is a polyurethane waterproof layer 5, and the anti-oxidation layer Layer 4 is a silicon carbide anti-oxidation layer 4, said reinforcing layer 3 is a carbon fiber layer arranged in a grid structure, and said breathable layer 2 is a 2:3 mixed layer of polyvinyl alcohol fiber and polypropylene fiber. The raw materials of the core board 1 and the weight parts of each raw material are:

[0090] Sandalwood powder: 22 parts;

[0091] Cizhu powder: 29 parts;

[0092] Non-alkaline chopped glass fiber: 11 parts;

[0093] Flax fiber: 9 parts;

[0094] 9 parts of animal bone meal;

[0095] Basalt fiber: 16 parts;

[0096] Methyl isothiazolinone: 21 parts;

[0097] 7 parts of silane coupling agent;

[0098] The sandalwood powder is a powder pulverized from scraps of sandalwood ...

Embodiment 3

[0109] A high-strength decorative material is composed of a waterproof layer 5, an anti-oxidation layer 4, a reinforcement layer 3, a gas-permeable layer 2, a composite core board 1 arranged in sequence; the waterproof layer 5 is a polyurethane waterproof layer 5, and the anti-oxidation layer Layer 4 is a silicon carbide anti-oxidation layer 4, said reinforcing layer 3 is a carbon fiber layer arranged in a grid structure, and said breathable layer 2 is a 2:3 mixed layer of polyvinyl alcohol fiber and polypropylene fiber. The raw materials of the core board 1 and the weight parts of each raw material are:

[0110] Sandalwood powder: 34 parts;

[0111] Cizhu powder: 16 servings;

[0112] Non-alkaline chopped glass fiber: 19 parts;

[0113] Flax fiber: 4 parts;

[0114] 16 parts of animal bone meal;

[0115] Basalt fiber: 16 parts;

[0116] Methyl isothiazolinone: 21 parts;

[0117] 7 parts of silane coupling agent;

[0118] The sandalwood powder is a powder pulverized from scraps of sandalw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com