A kind of zn-li-mn series zinc alloy and its preparation method and application

A zn-li-mn, zinc alloy technology, applied in medical science, prosthesis, etc., can solve the problems of toxic and side effects of degradation products, loss of mechanical integrity of implants, etc., achieve excellent mechanical properties, improve plasticity, and strengthen the matrix Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

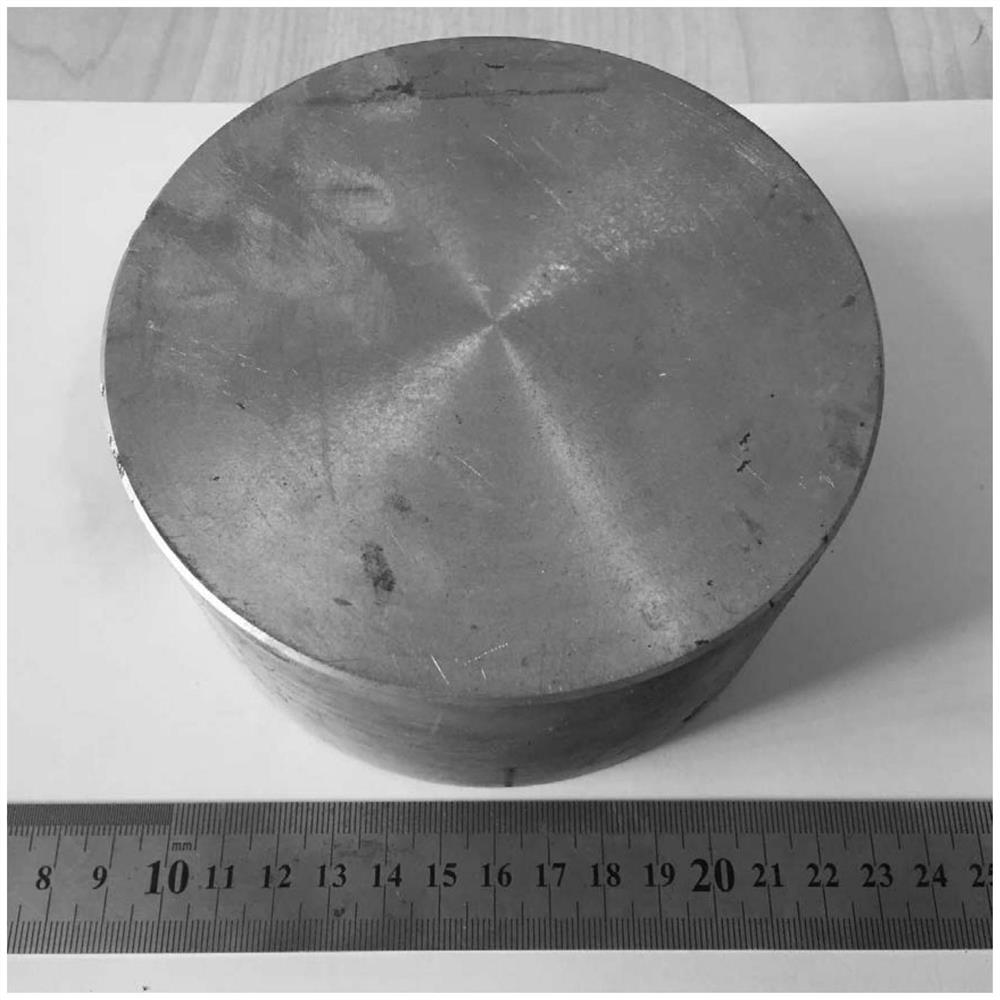

[0068] Embodiment 1, preparation as-cast Zn-Li-Mn series zinc alloy

[0069] Using pure zinc (99.99wt.%), zinc-lithium intermetallic compound, zinc-manganese intermetallic compound as raw materials, according to the mass ratio in the following table:

[0070] Zn Li mn 99.8% 0.1% 0.1% 99.5% 0.1% 0.4% 99.1% 0.1% 0.8% 99.5% 0.4% 0.1% 99.2% 0.4% 0.4% 98.8% 0.4% 0.8% 99.1% 0.8% 0.1% 98.8% 0.8% 0.4% 98.4% 0.8% 0.8%

[0071] mixed, in CO 2 +SF 6 Under the protection of the atmosphere, smelt at 600 ° C, stir evenly, and after standing, pouring and cooling, the Zn-Li-Mn series zinc alloy (such as figure 1 shown).

Embodiment 2

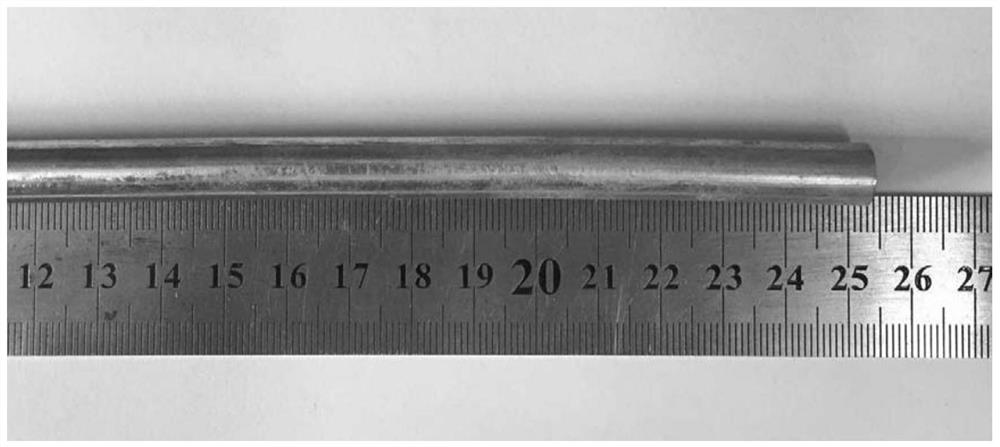

[0072] Embodiment 2, preparation extruded state Zn-Li-Mn series zinc alloy

[0073] First, according to the steps in Example 1 of the present invention, the as-cast Zn-Li-Mn alloy ingot is prepared, and the Zn-Li-Mn alloy rod is prepared by extrusion (such as figure 2 shown), using radial extrusion, ingot heat preservation for 2h, heat preservation temperature 260°C or 220°C, extrusion temperature 260°C or 220°C, extrusion ratio 36 or 16, extrusion speed 1mm / s to prepare the diameter It is a 10mm Zn-Li-Mn alloy rod.

Embodiment 3

[0074] Embodiment 3, preparation rolling state Zn-Li-Mn series zinc alloy

[0075] First, the as-cast Zn-Li-Mn zinc alloy ingot is prepared according to the steps in Example 1, and the Zn-Li-Mn zinc alloy plate is prepared by rolling (such as image 3 shown), using unidirectional rolling, followed by hot rolling and finish rolling. Before rolling, keep warm at the rolling temperature for 15 minutes. Carry out down-rolling, down-rolling 0.5mm in each pass, the amount of reduction in each pass is 2%, and the final thickness of the plate is 2mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com