Unattended production method for aluminum electrolytic prebaked anode replacement and insulation material maintenance

A technology of prebaked anodes and production methods, which is applied in the field of normal anode replacement and insulation material maintenance on the pole of the electrolytic cell, can solve problems such as labor costs, achieve stable operation, optimize operating status, and reduce labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

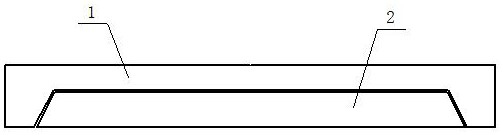

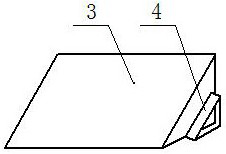

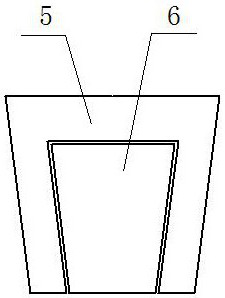

Image

Examples

Embodiment

[0031] Embodiment: An unattended production method for aluminum electrolytic prebaked anode replacement and insulation material maintenance, the specific steps are as follows:

[0032] A. Before replacing the prebaked anode, first clean the aluminum oxide attached to the upper surface of the anode butt out of the tank;

[0033] B. Use a multi-functional crane to open the edge along the periphery of the anode residue;

[0034] C. Lift the anode residue out of the electrolytic cell with a multifunctional crane;

[0035] D. Before the new prebaked anode is put into the tank, spray the surface of the prebaked anode with anti-oxidation paint;

[0036] E. Place insulation blocks on the upper surface of the new prebaked anode so that the upper surface of the anode is in a horizontal plane, and then place the maintenance-free upper insulation plate on the surface of the prebaked anode;

[0037] F. Put the new anode into the electrolytic cell with a multifunctional crane, and tighten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com