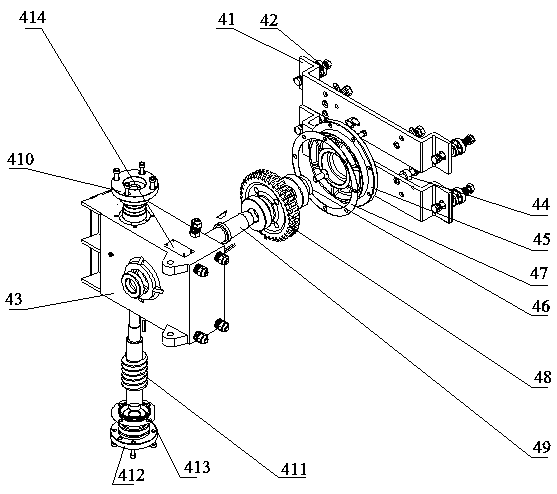

Decelerator assembly for troweling machine

A technology of reducer and trowel, applied in mechanical equipment, transmission parts, roads, etc., can solve the problems of unstable work, time-consuming and laborious, uneven and smooth surface, etc., achieve compact structure design, improve construction efficiency, Achieving the effect of speed coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

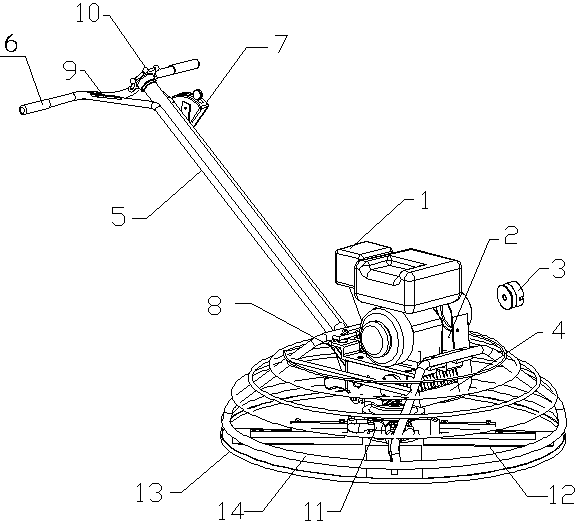

[0012] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments.

[0013] like figure 2 The troweling machine shown includes a gasoline engine 1, a transmission assembly 2, a clutch 3, a reducer 4, a handle assembly 5, a handle 6, a parking device 7, a pallet 8, an oil quantity controller 9, and a steamed knife adjustment 10, cross seat assembly 11, blade assembly 12, wiping disc assembly 13 and protective ring 14, the supporting plate 8 is fixedly connected with the handle assembly 5 and the protective ring 14 respectively, gasoline is placed on the supporting plate 8 Engine 1, a clutch 3 is connected to the side of the gasoline engine 1, a cross seat assembly 11 is connected to the lower part of the gasoline engine 1 through a reducer 4, and a plurality of blade assemblies 12 are fixedly connected to the cross seat assembly 11. A blade assembly 12 is connected with a steamed knife adjuster 10, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com