A method for inhibiting the longitudinal protruding of sagd steam chamber

A steam chamber, vertical technology, applied in the field of inhibiting the longitudinal protruding of SAGD steam chamber, can solve the problems of reduced oil production, poor development effect of SAGD, shrinkage of steam chamber, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

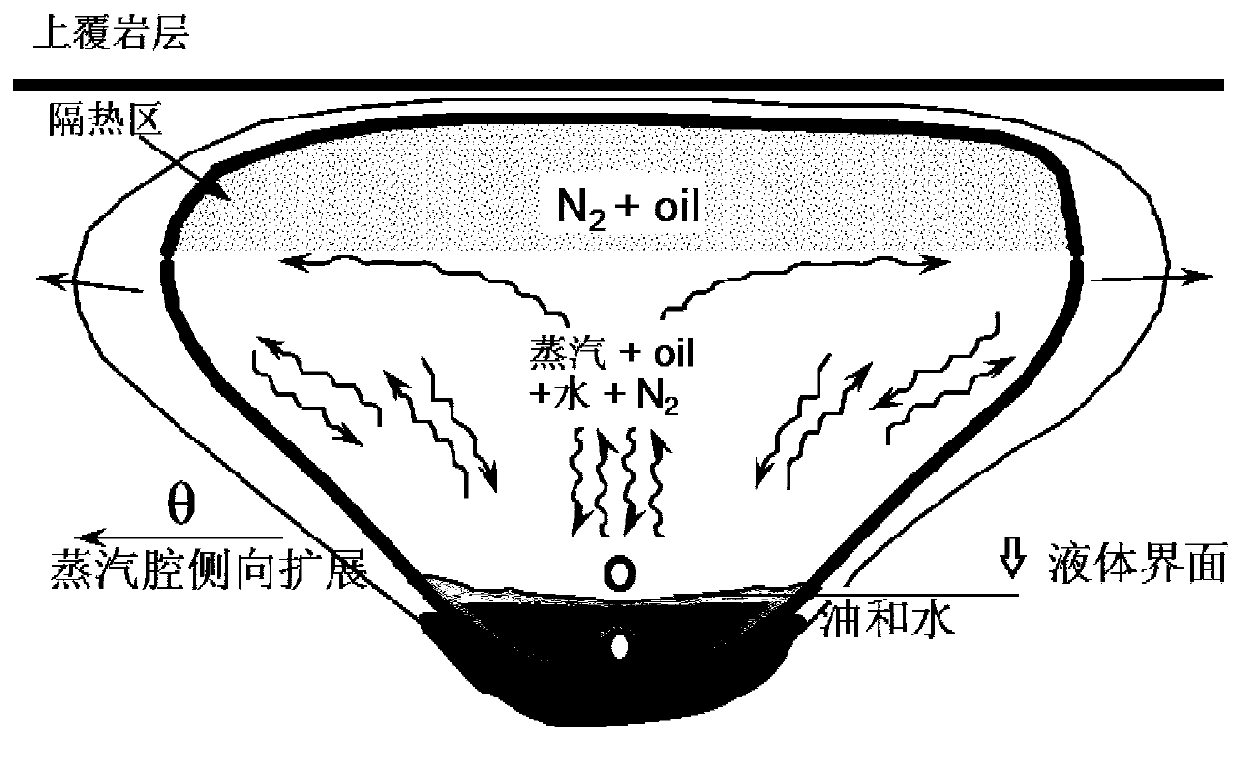

Embodiment 1

[0084] A certain oil reservoir is an ultra-heavy oil reservoir with top and bottom water. There is no pure mudstone barrier between the oil layer and the surrounding water body, but the thickness of the "bitumen shell" at the oil-water interface is 0.5-2m. The average thickness of the oil layer is 77.0m, and the maximum is 126.6m. use as Image 6 The vertical well + horizontal well combination SAGD development shown. The test area forms a large steam cavity as a whole. Monitoring data show that the height of the steam cavity near Well G4 is about 90m, while other surrounding wells are 50m to 70m away from the oil top, which indicates that the steam cavity near G4 well is protruding in the longitudinal direction.

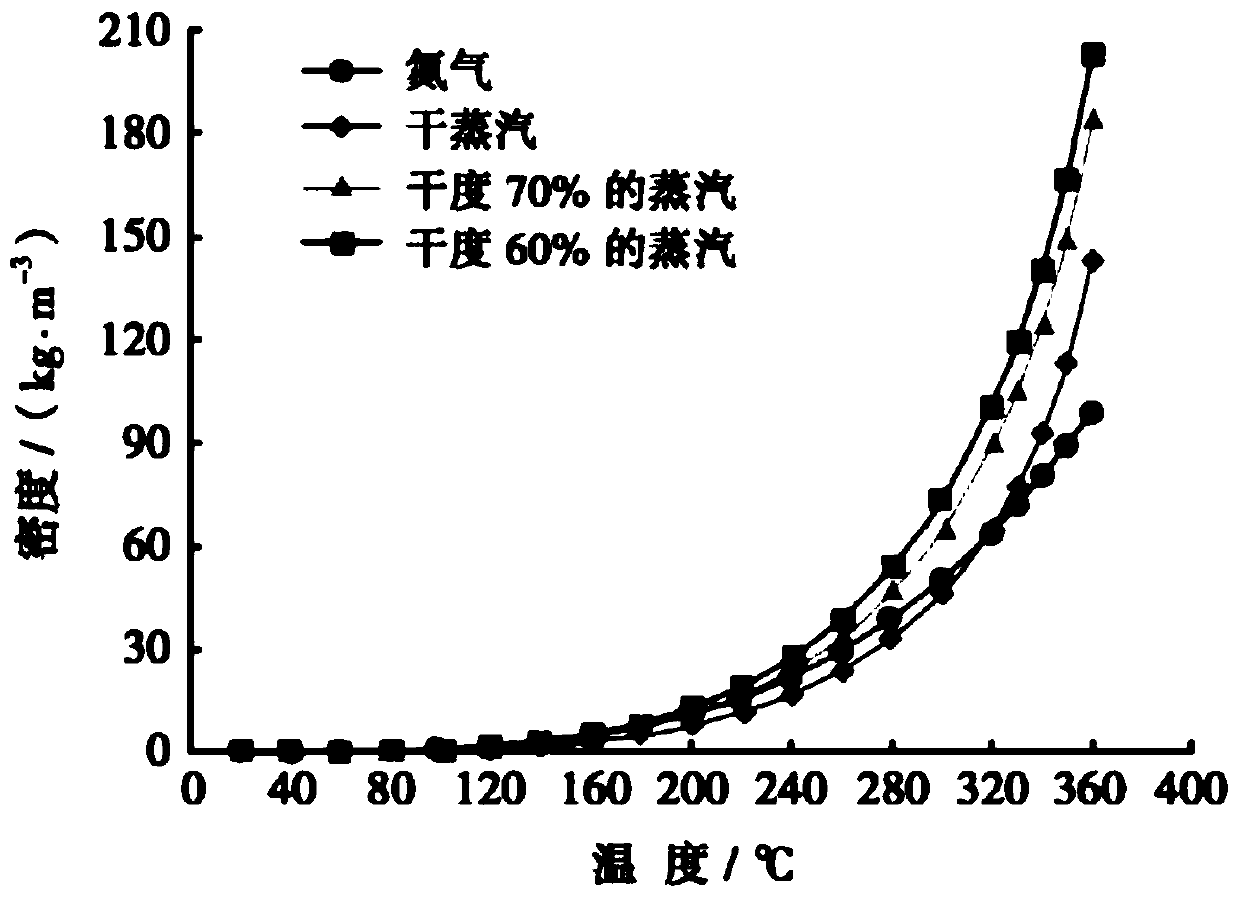

[0085] According to well monitoring data and reservoir numerical simulation, the height of the intrusion chamber is about 30m, the plane range is about 70m, and the temperature of the highest point of the steam chamber reaches 244°C.

[0086] Firstly, normal temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com