Construction method of a device capable of preventing deformation of ballastless track tunnel bottom

A ballastless track and construction method technology, applied in tunnels, shaft equipment, earth-moving drilling and other directions, can solve the problem that the smoothness of the line cannot be guaranteed, and achieve the effect of saving renovation and maintenance costs, ensuring safety, and facilitating construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

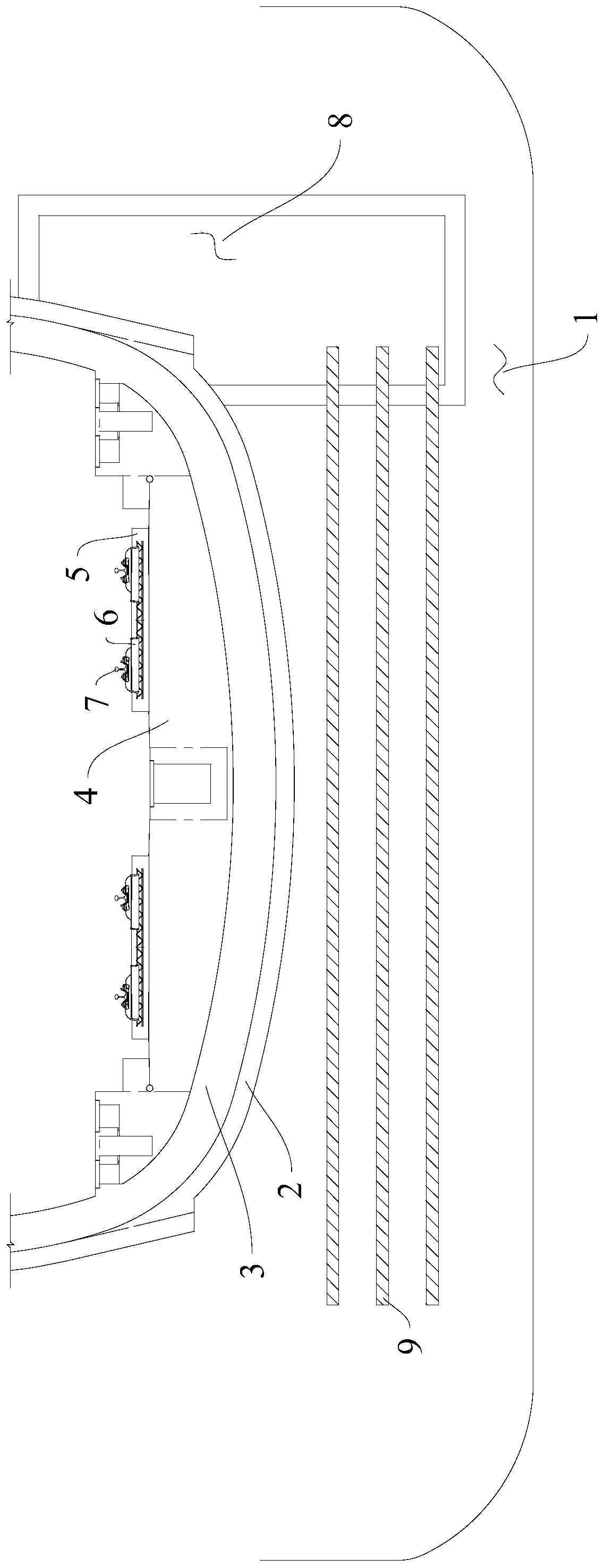

[0029] Such as figure 1 As shown, the bottom part of the ballastless track tunnel mainly includes the tunnel bottom surrounding rock 1, and above the tunnel bottom surrounding rock 1, the tunnel invert initial support 2, the tunnel invert lining 3, and the invert filling layer 4 are successively arranged. A ballast bed slab 5 is laid on the inverted arch filling layer 4 , a sleeper 6 is arranged on the ballast bed slab 5 , and a ballastless track 7 is installed on the sleeper 6 .

[0030] A device for preventing the deformation of the ballastless track tunnel bottom, comprising several transverse boreholes 9 with a diameter of 10cm-30cm arranged in the surrounding rock 1 of the tunnel bottom, each of the transverse boreholes 9 is arranged in the tunnel along the transverse direction of the tunnel directly below the inverted arch primary support 2, and the length of the transverse borehole 9 is greater than the transverse length of the tunnel. The transverse boreholes 9 are ar...

Embodiment 2

[0033] Such as figure 1 Shown, a kind of construction method of the device that can prevent the deformation of ballastless track tunnel bottom, comprises any one described device that can prevent the deformation of ballastless track tunnel bottom, its construction method is:

[0034] Step 1: setting the drilling studio 8 on one side of the tunnel;

[0035] Step 2: Perforating horizontally along the tunnel in the working chamber 8, so as to form several transverse drilling holes 9;

[0036] Step 3: laying a support pipe on the inner wall of the transverse borehole 9;

[0037] Step 4: Set strain gauges on the support pipe for regular detection;

[0038] Step 5: When the detected stress value of the strain gauge tends to be stable, the transverse borehole 9 is grouted and closed.

[0039] This construction method can greatly reduce the arching deformation of the tunnel bottom and release part of the tunnel bottom stress through the set horizontal drilling; through the regular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com