Alkaline storage cell

A storage battery, alkaline technology, applied in the field of alkaline storage batteries, to achieve the effects of improving manufacturing efficiency, suppressing heat generation, and easy miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

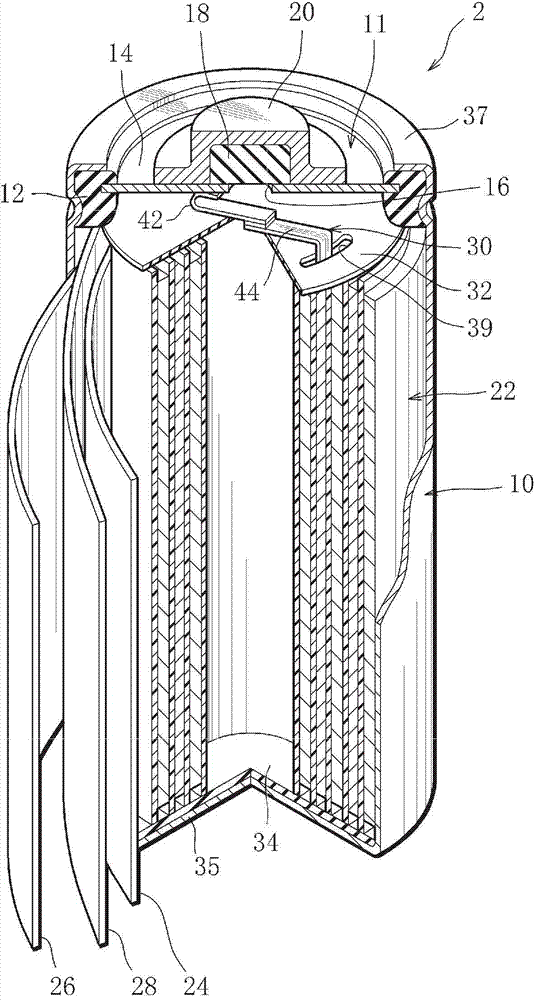

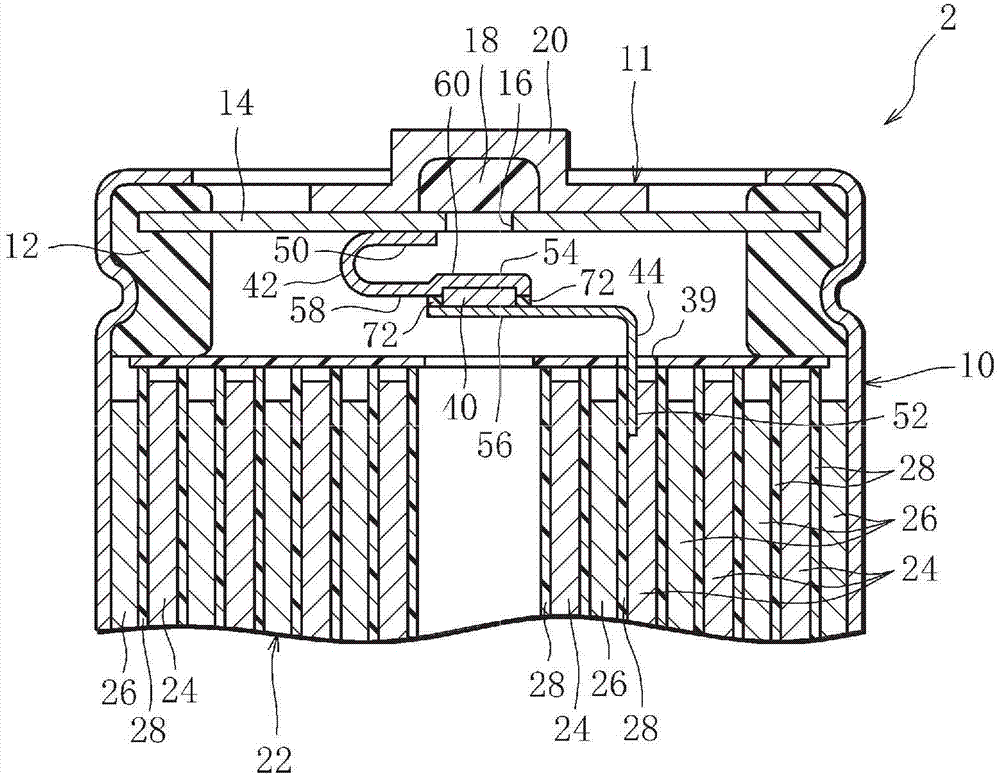

[0043] As the battery of Embodiment 1 to which the present invention is applied, for example, to apply the present invention to figure 1 The case of the shown AAA size cylindrical nickel-metal hydride storage battery (hereinafter referred to as battery) 2 will be described as an example.

[0044] Such as figure 1 As shown, the battery 2 has a bottomed cylindrical case 10 with an open upper end. The casing 10 is conductive, and its bottom wall 35 functions as a negative terminal. A sealing body 11 is fixed on the opening of the casing 10 . The sealing body 11 includes a cover plate 14 and a positive terminal 20 , and seals the case 10 and provides the positive terminal 20 . The cover plate 14 is a conductive disc-shaped member. A cover plate 14 and an annular insulating filler 12 surrounding the cover plate 14 are disposed in the opening of the housing 10 , and the insulating filler 12 is fixed to the opening edge 37 of the housing 10 by riveting the opening edge 37 of the ...

Embodiment approach 2

[0068] The battery of Embodiment 2 to which the present invention is applied will be described.

[0069] The battery of Embodiment 2 differs from the battery 2 of Embodiment 1 only in that the second overlapping end portion 82 including the second lead half body 80 is also provided with the positive electrode lead 31 embedded in the concave portion 84 . Therefore, members and parts that perform the same functions as those in Embodiment 1 that have already been described will be assigned the same reference numerals, their description will be omitted, and only the different points will be described.

[0070] First, if Image 6 As shown, the second lead half body 80 involved in the positive electrode lead 31 has a second embedding recess 84 on its second overlapping end portion 82 into which the PTC thermistor 40 can be embedded. The second fitting recess 84 has the same shape as the first fitting recess 70 provided in the first lead half body 42 . That is, the shape in plan vi...

Embodiment 1

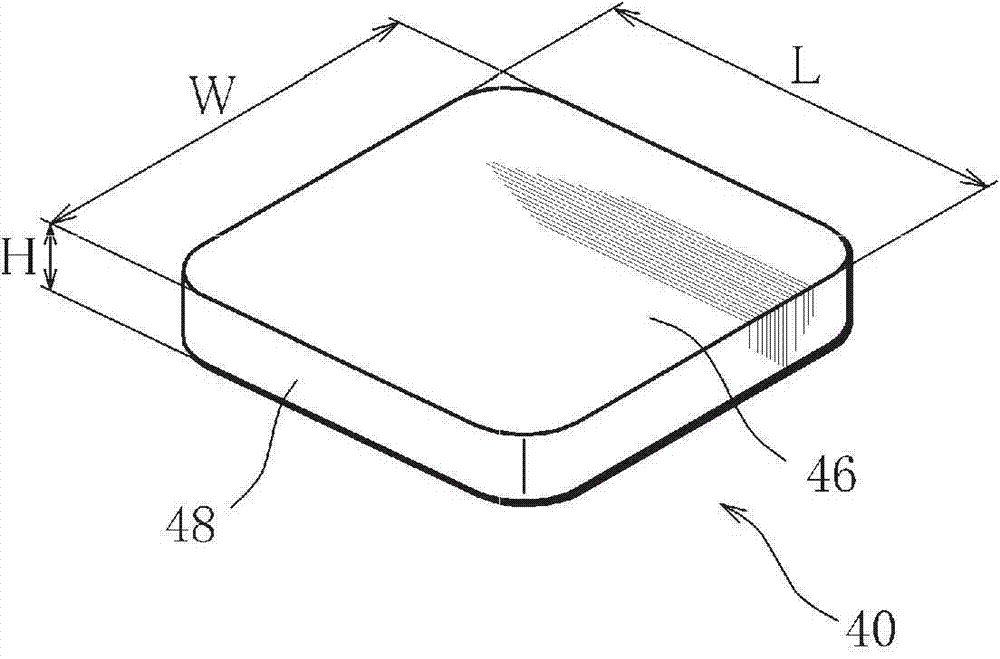

[0075] Such as image 3 As shown, a PTC thermistor 40 having a substantially rectangular plate shape with a length (L) of 3 mm, a width (W) of 3 mm, and a thickness (H) of approximately 1.0 mm and an operating temperature of 90° C. was prepared. In addition, the corners of the PTC thermistor 40 are formed in an arc shape.

[0076] On the other hand, as the first lead half body 42 and the second lead half body 44 , strip-shaped bodies made of nickel with a thickness of about 0.2 mm were prepared. These first and second lead halves 42, 44 are as Figure 4 As shown, it includes rectangular overlapping end portions 54, 56 having a length (L1) of 3.5 mm and a width (W1) of 3.5 mm, and body portions 62, 66 having a width (W2) of 3 mm. Further, between the overlapping end portions 54, 56 and the main body portions 62, 66, narrow portions 64, 68 having a width (W3) of 2.5 mm and a length (L2) of 1 mm are provided.

[0077] here, as Figure 4 , Figure 5 As shown, the overlapping ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface temperature | aaaaa | aaaaa |

| contact resistance | aaaaa | aaaaa |

| contact resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com