Construction method of a prevention and control device for ballastless track tunnel bottom deformation

A preventive control, ballastless track technology, applied in tunnels, shaft equipment, earth-moving drilling, etc., can solve the problem that the line smoothness cannot be guaranteed, reduce the volume increment of surrounding rock, ensure safety, and ensure the safety of tunnel operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

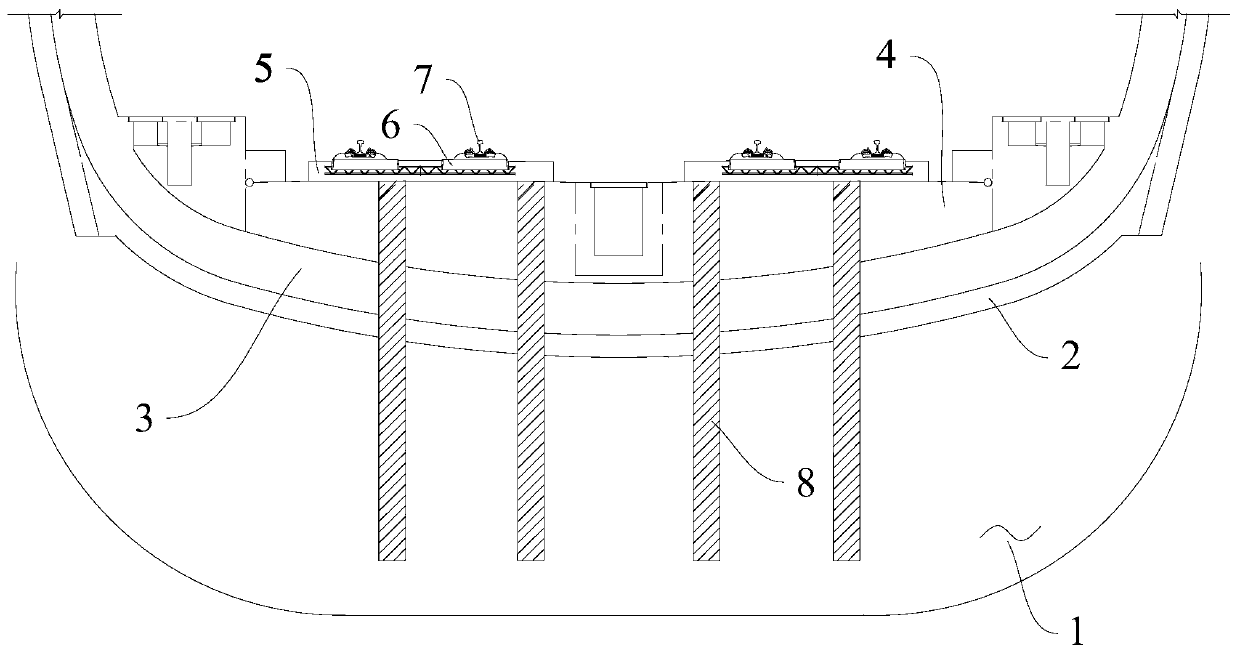

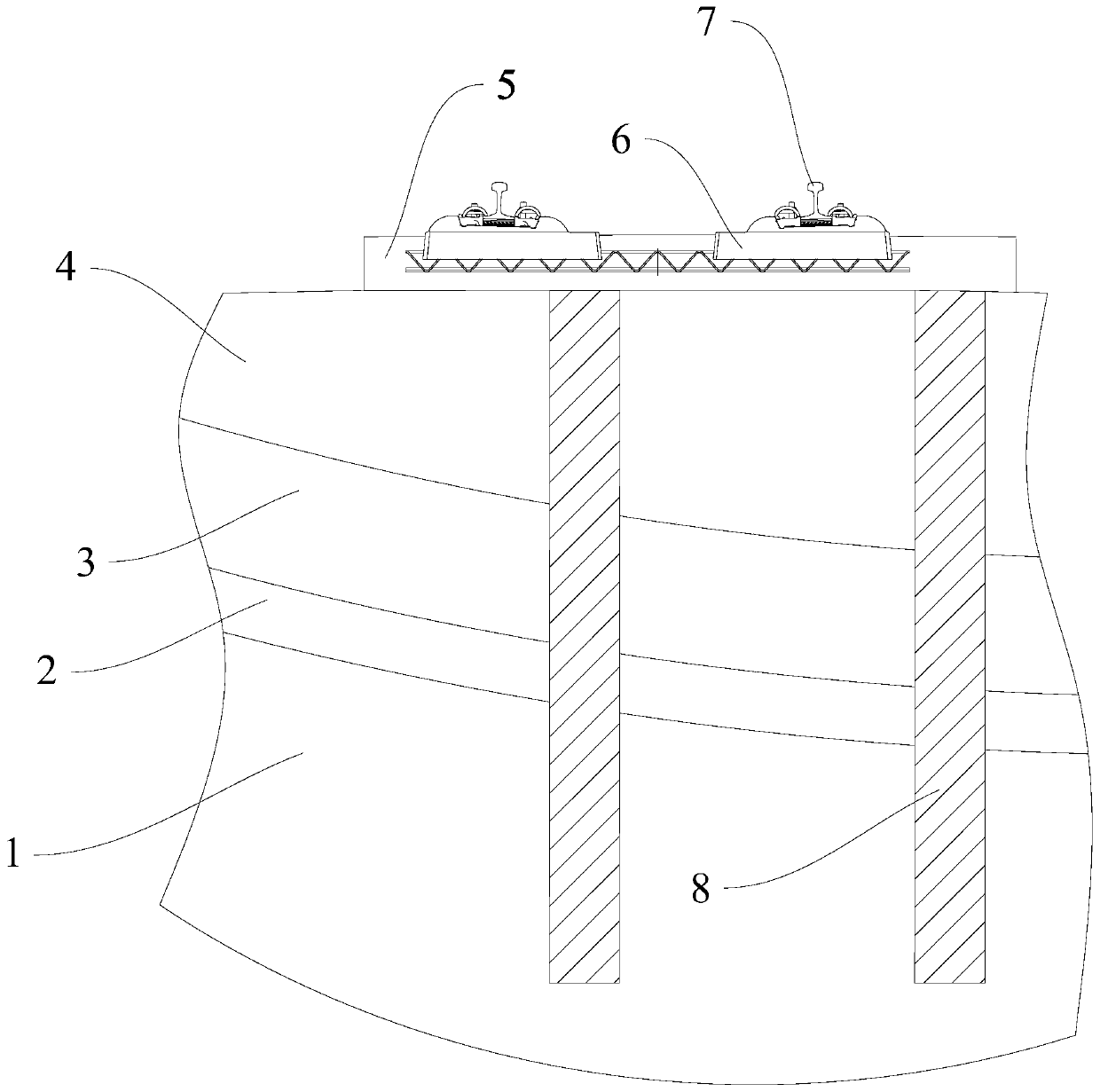

[0030] Such as Figure 1-Figure 2 As shown, the bottom part of the ballastless track tunnel mainly includes the tunnel bottom surrounding rock 1, on which the primary support 2, the secondary lining 3, and the inverted arch filling layer 4 are successively arranged above the tunnel bottom surrounding rock 1. A track bed slab 5 is laid on the arch filling layer 4 , a sleeper 6 is arranged on the track bed slab 5 , and a ballastless track 7 is installed on the sleeper 6 .

[0031] A prevention and control device for ballastless track tunnel bottom deformation, comprising vertically driving from the inverted arch filling layer 4 into the tunnel bottom surrounding rock 1 after the construction of the inverted arch filling layer 4 is completed and before the ballast bed slab 5 is laid. Several vertical boreholes 8 with a diameter of 10cm-30cm. And in described vertical borehole 8 inwall, be provided with support pipe, described support pipe is PVC pipe or steel pipe, is provided w...

Embodiment 2

[0035] A construction method of a prevention and control device for ballastless track tunnel bottom deformation, including any one of the above-mentioned prevention and control device for ballastless track tunnel bottom deformation, and the construction method is as follows:

[0036] Step 1: After the construction of the inverted arch filling layer 4 is completed, vertically drill holes 8 from the inverted arch filling layer 4 into the surrounding rock 1 at the bottom of the tunnel before the ballast bed slab 5 is laid;

[0037] Step 2: laying a supporting pipe on the inner wall of the vertical borehole 8;

[0038] Step 3: Set strain gauges on the support pipe and check them regularly;

[0039] Step 4: When the stress results of the strain gauge tend to be stable, the vertical borehole 8 is grouted and closed.

[0040]This construction method can greatly reduce the arching deformation of the tunnel bottom and release part of the tunnel bottom stress through the vertical drill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com