Natural gas engine transient state compensation control system and method

A compensating control and engine technology, applied in engine control, electrical control, machine/engine, etc., can solve problems such as insufficient engine power, poor response to transient conditions, poor transient response, etc., to achieve fuel injection volume or Accurate charge air flow, improved exhaust emission performance, and improved transient response effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

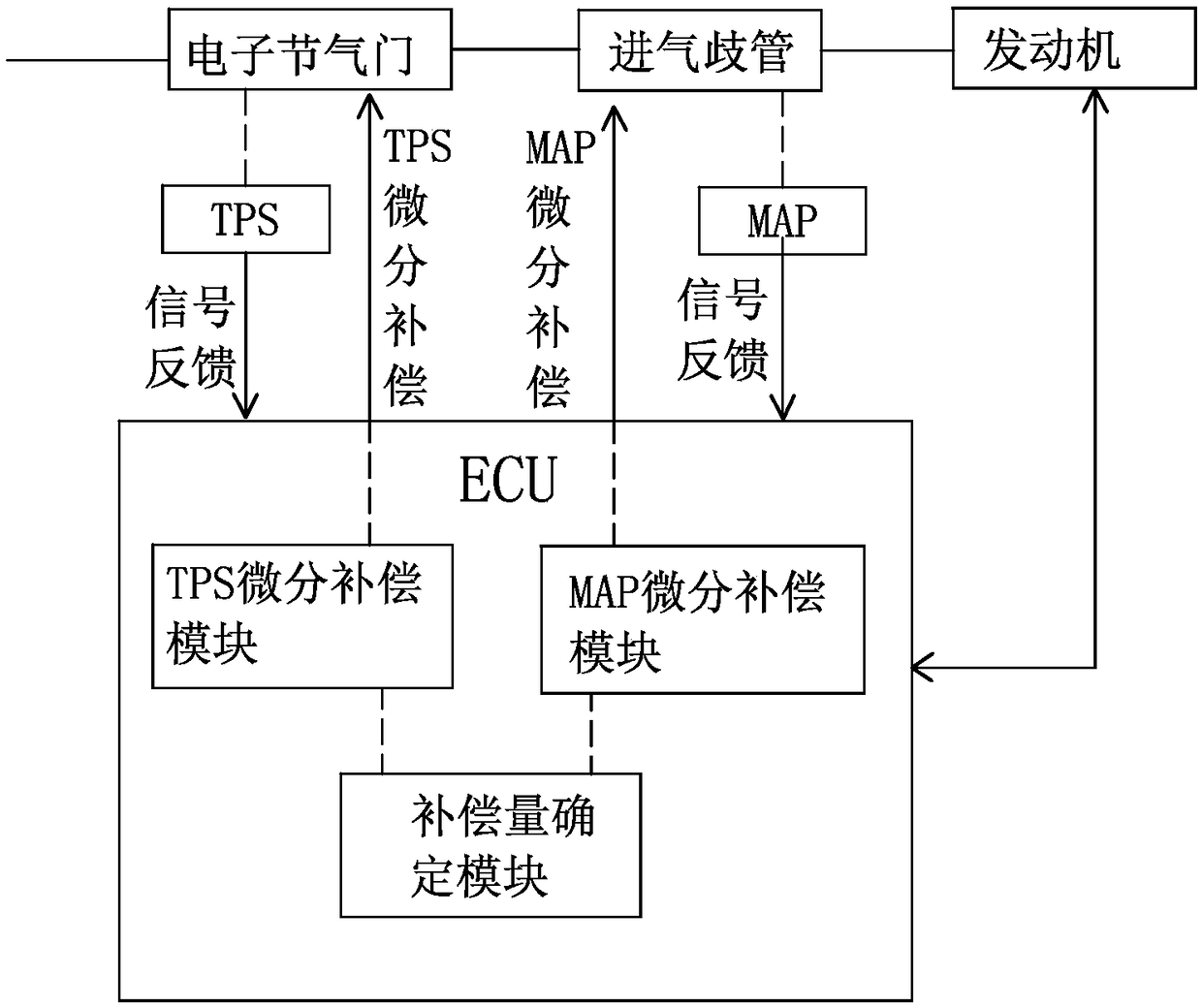

[0029] Such as figure 1 to combine figure 2 As shown, the transient compensation control system of a natural gas engine includes a throttle position sensor (TPS for short) and an intake manifold pressure sensor (MAP for short) electrically connected to the engine ECU, and the throttle position sensor TPS is installed on the electronic throttle , the intake manifold pressure sensor, that is, MAP, is installed on the intake manifold, and the specific installation position is the same as that of the prior art, and will not be repeated here.

[0030] The engine ECU includes a TPS differential compensation module, a MAP differential compensation module and a compensation amount determination module.

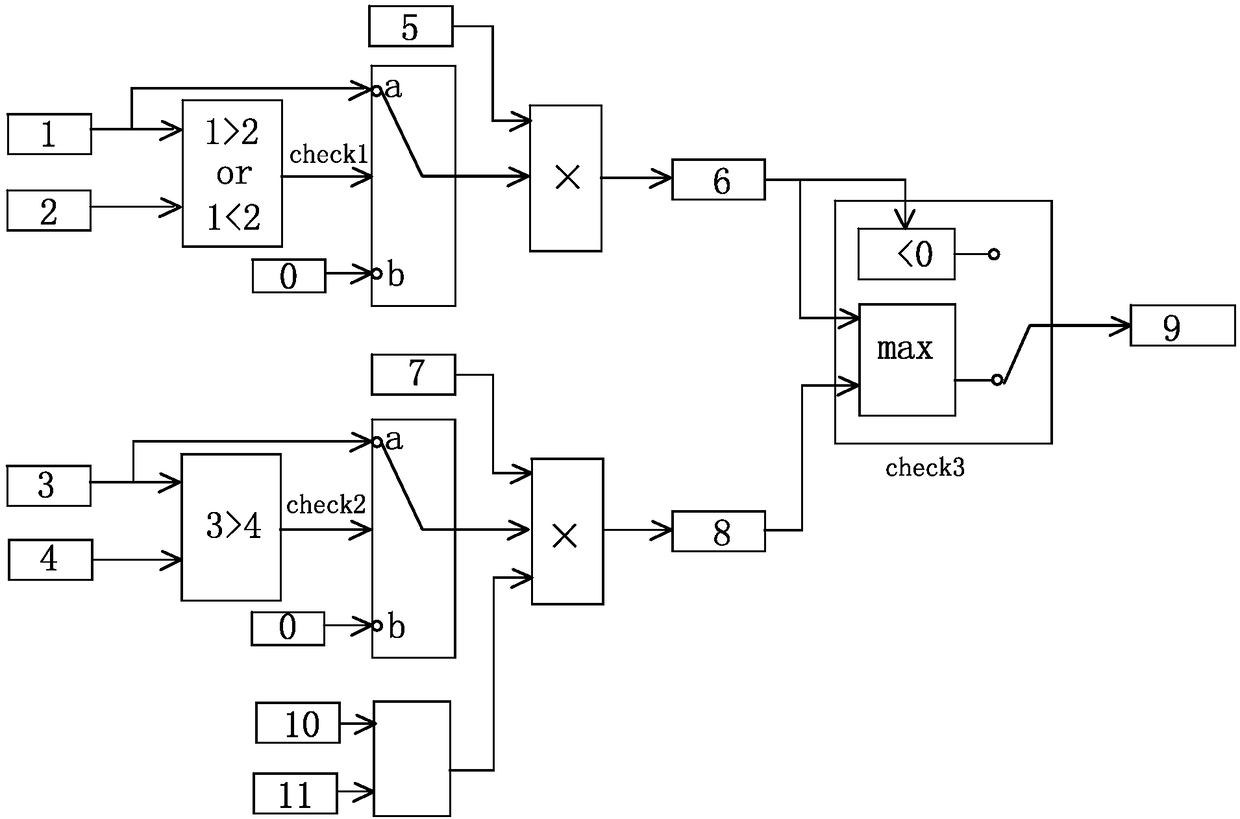

[0031] The TPS differential compensation module determines the TPS charge air compensation flow 8 according to the throttle opening change rate 3 transmit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com