High-temperature and high-pressure wellhead thermal recovery valve

A high-temperature, high-pressure, thermal recovery technology, applied to sliding valves, valve details, valve devices, etc., can solve problems such as short service life, low efficiency, and large operating force distance, so as to ensure service life, facilitate valve opening and closing, and ensure reliability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

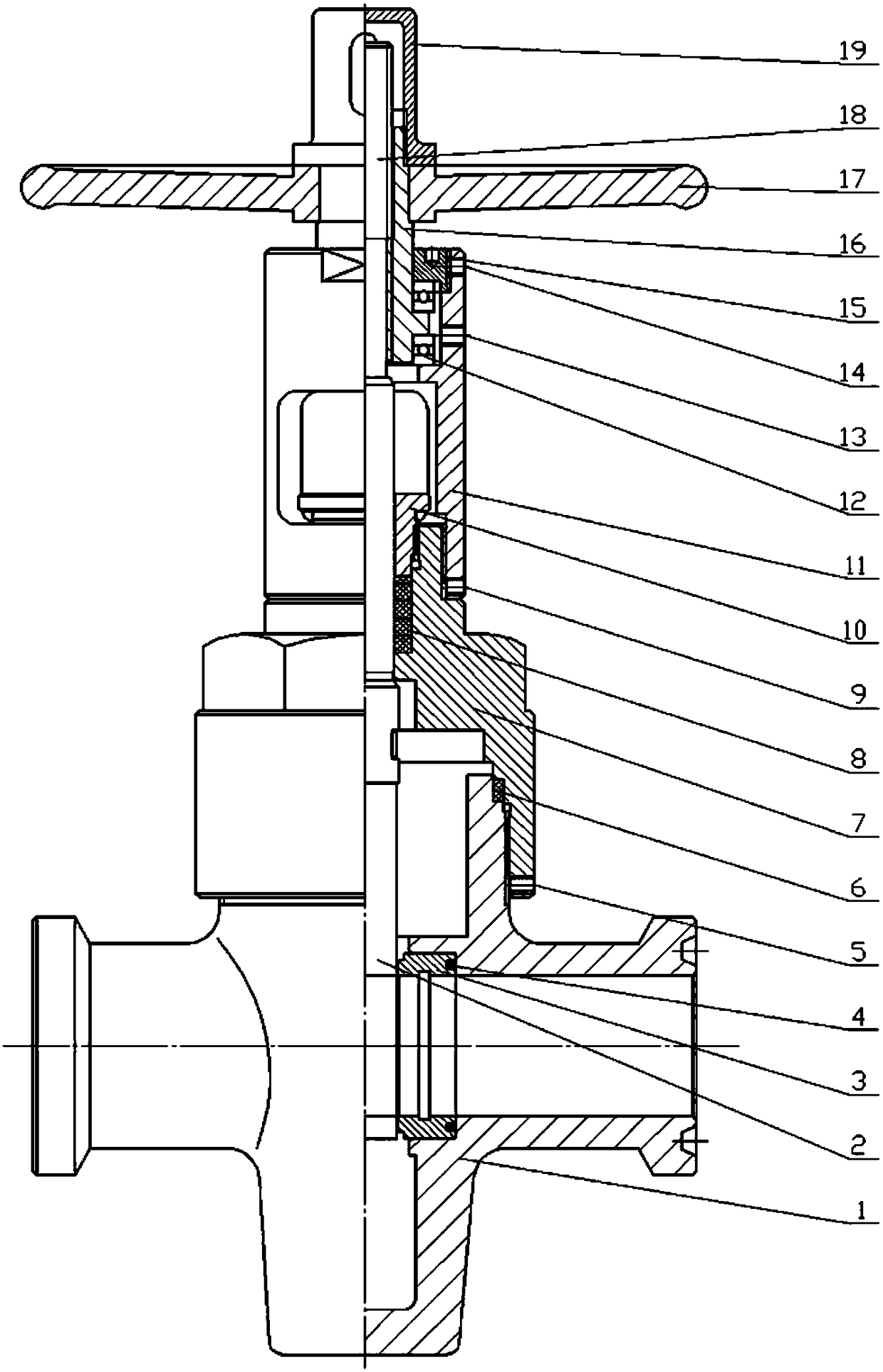

[0012] As shown in the figure, valve body 1, gate plate 2, sealing ring 3, reinforced special flexible graphite 4, positioning screw 5, sealing gasket 6, connecting sleeve 7, combined sealing packing 8, tightening screw 9, packing gland 10 , bracket 11, bearing 12, oil cup 13, tightening screw 14, set screw 15, valve stem nut 16, handwheel 17, valve stem 18, valve cover 19.

[0013] As shown in the figure, for the high-temperature and high-pressure wellhead thermal recovery valve, a pair of metal sealing rings 3 are arranged on the section of the fluid channel 10 inside the valve body, embedded in the valve body, and communicated with the inlet and outlet of the valve. The channel is the up and down movement of the spool cavity. The gate plate 2 cuts into the pair of parallel sealing rings 3 to cut off the flow channel, that is, the valve is closed or connected. The gate plate moves up and down in the fluid channel in the valve body, that is, a pair of sealing rings. The valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com