Filling head, carbon dioxide cracker and carbon dioxide cracker unit

A carbon dioxide and cracker technology, applied in weapon accessories, blasting cartridges, ammunition and other directions, can solve the problems of complex parallel wiring, hidden dangers in production safety, and easily broken wires, and achieve the effect of eliminating hidden dangers in production safety and eliminating the electrification of the pipe body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

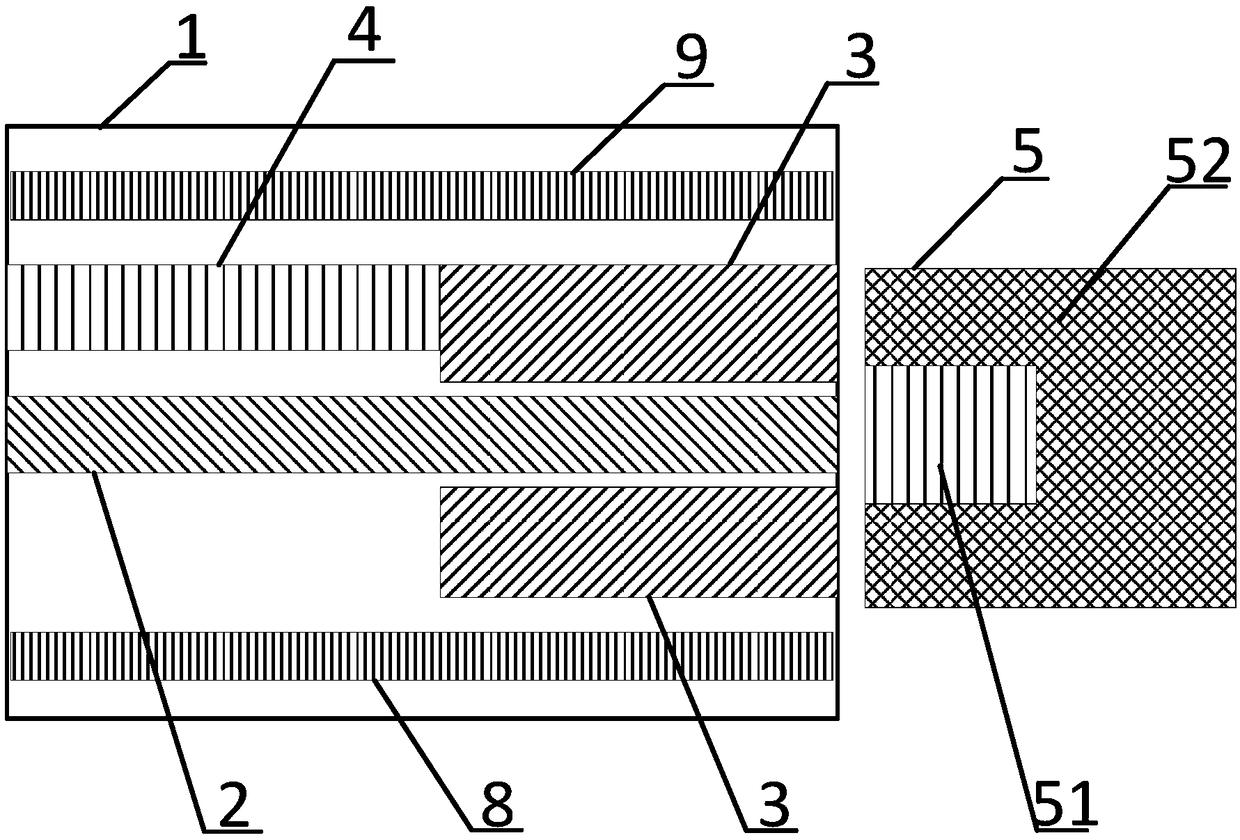

[0026] figure 1 This is a schematic structural diagram of a filling head provided in the first embodiment of the present invention. This embodiment can be applied to the case where the initiating device is electrically heated by the filling head in the carbon dioxide cracker. Such as figure 1 As shown, the filling head includes a housing 1 in which an axial positive electrode 2, a central electrode 3 and an axial negative electrode 4 are arranged.

[0027] Among them, the axial positive pole 2 is connected with the detonating device 5; the detonating device 5, the central electrode 3 and the axial negative pole 4 are sequentially connected in series.

[0028] Optionally, the axial positive electrode 2 is arranged on the central axis of the housing 1. The center electrode 3 and the axial electrode 2 are coaxially arranged, but the two electrodes are not directly connected. The axial negative electrode 4 is arranged at a position away from the central axis. The axial positive pole ...

Embodiment 2

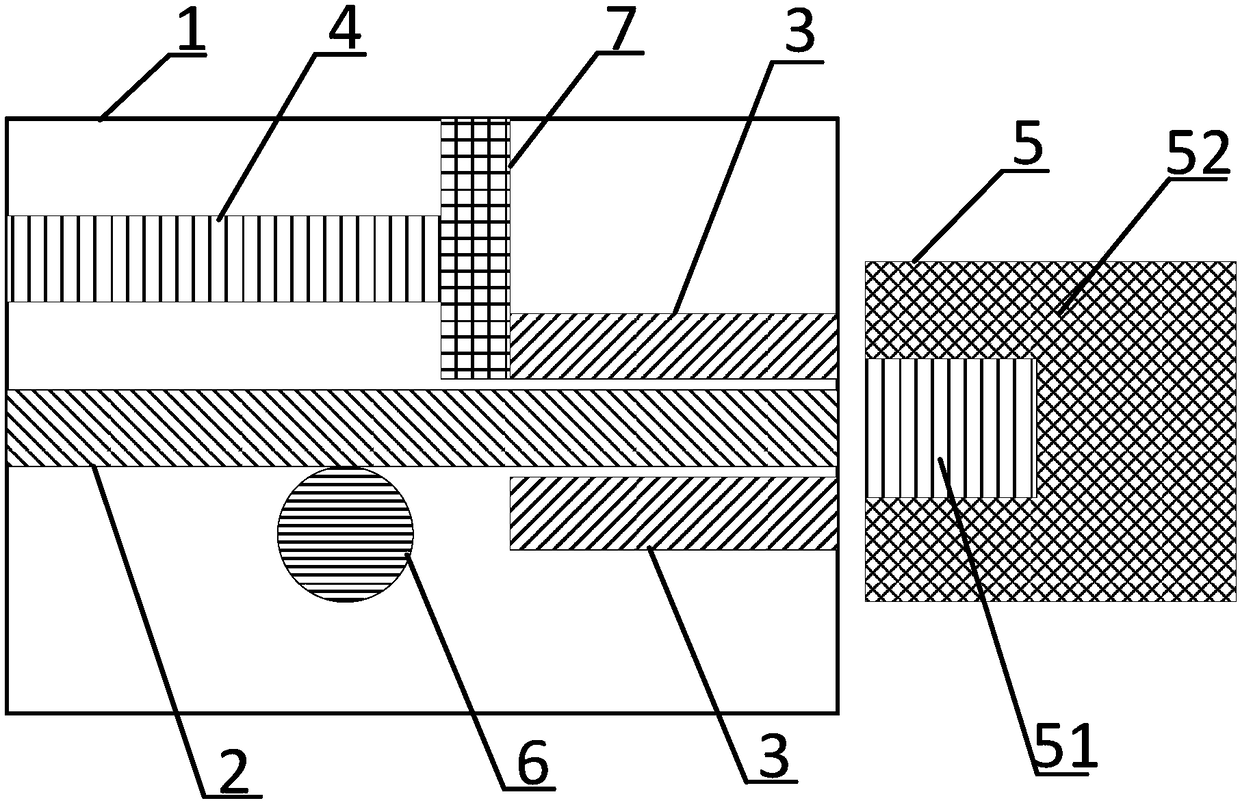

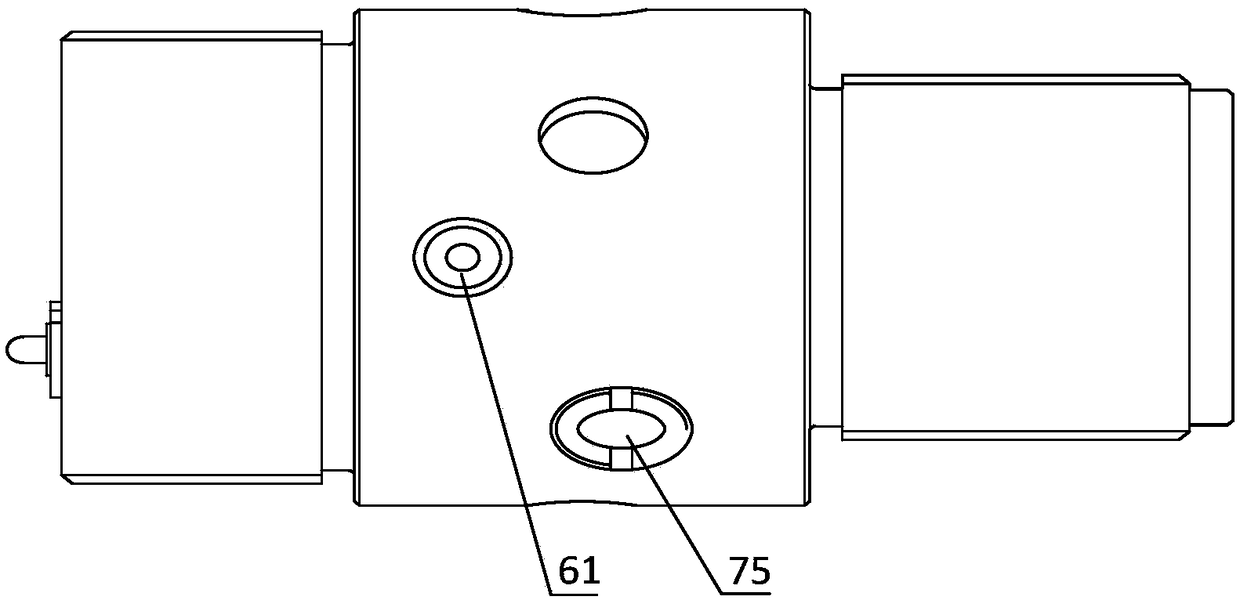

[0036] figure 2 Is a schematic structural diagram of a filling head provided in the second embodiment of the present invention; image 3 It is a front view of a filling head provided in the second embodiment of the present invention; Figure 4 Is a side view of a filling head provided in the second embodiment of the present invention; Figure 5 Yes Figure 4 Sectional view along the A-A direction. Such as Figure 2 to Figure 5 As shown, the second embodiment of the present invention is optimized on the basis of the above embodiments: the filling head further includes: a radial positive electrode connected to the axial positive electrode, and a radial negative electrode connected to the axial negative electrode.

[0037] After optimization, such as figure 2 As shown, a filling head includes: a housing 1, an axial positive electrode 2, a center electrode 3, an axial negative electrode 4, a radial positive electrode 6 and a radial negative electrode 7.

[0038] Among them, the axial...

Embodiment 3

[0051] Image 6 A schematic diagram of the structure of a carbon dioxide cracker provided in the third embodiment is given. This embodiment can be applied to the situation of safely blasting coal mines. Such as Image 6 As shown, the carbon dioxide cracker includes a filling head 200 according to any embodiment of the present invention. In addition to the filling head 200, the carbon dioxide cracker also includes an initiating device 210, a fracturing tube 220 and an energy venting head 230.

[0052] Among them, the filling head 200, the detonating device 210, the fracturing tube 220 and the energy venting head 230 are connected in series. Preferably, the filling head 200, the detonating device 210, the fracturing tube 220, and the energy venting head 230 are connected in sequence by threads to achieve a stable connection and facilitate installation and maintenance.

[0053] In this embodiment, the initiating device 210 can be electrically heated only by the filling head 200, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com