Vibration noise collector

A collection machine, noise technology, applied to measuring devices, instruments, measuring ultrasonic/sonic/infrasonic, etc., can solve problems such as inability to intuitively and accurately judge whether a product is qualified, inaccurate test results, and increased labor costs. Achieve the effect of simple structure, improved accuracy and controllability, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

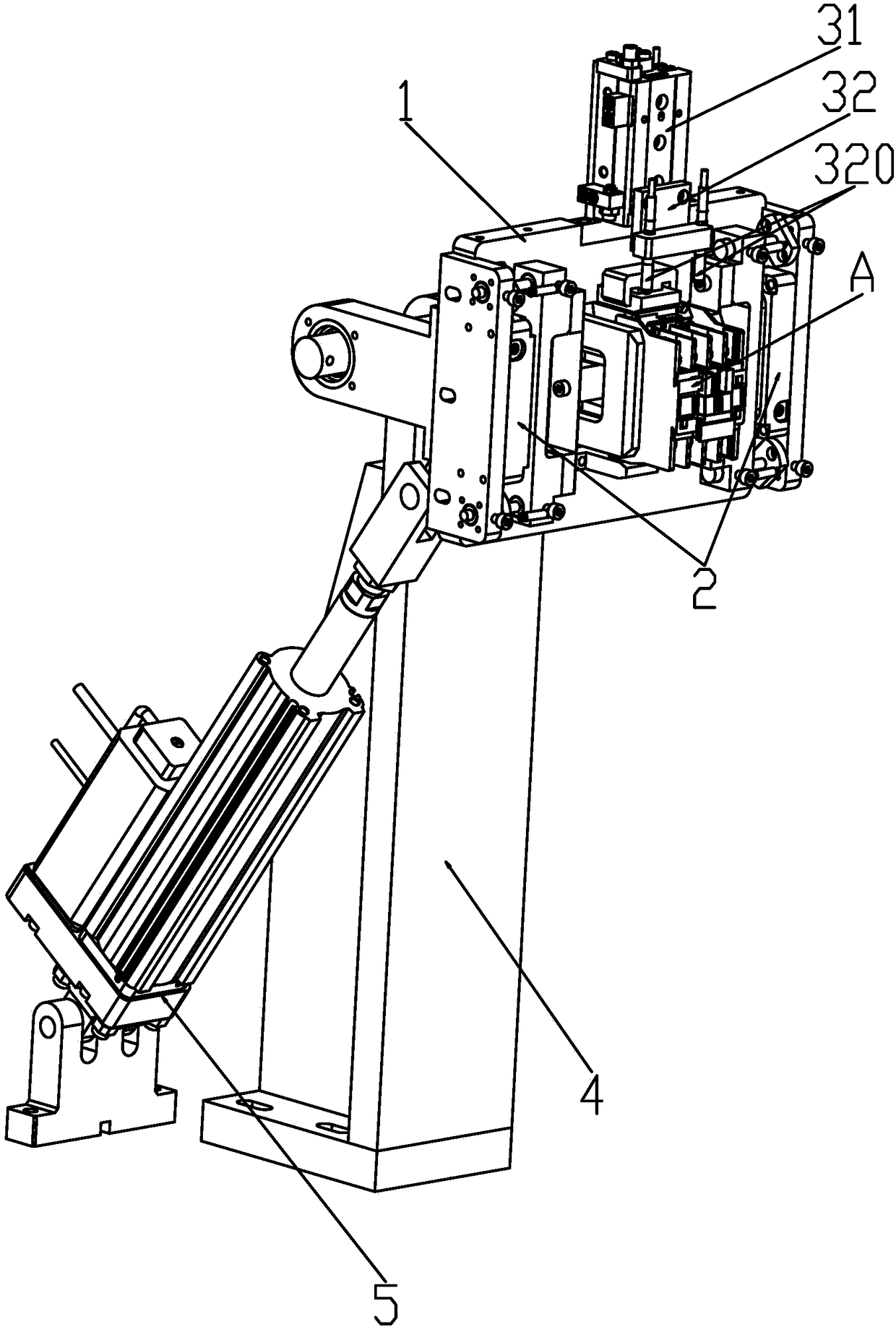

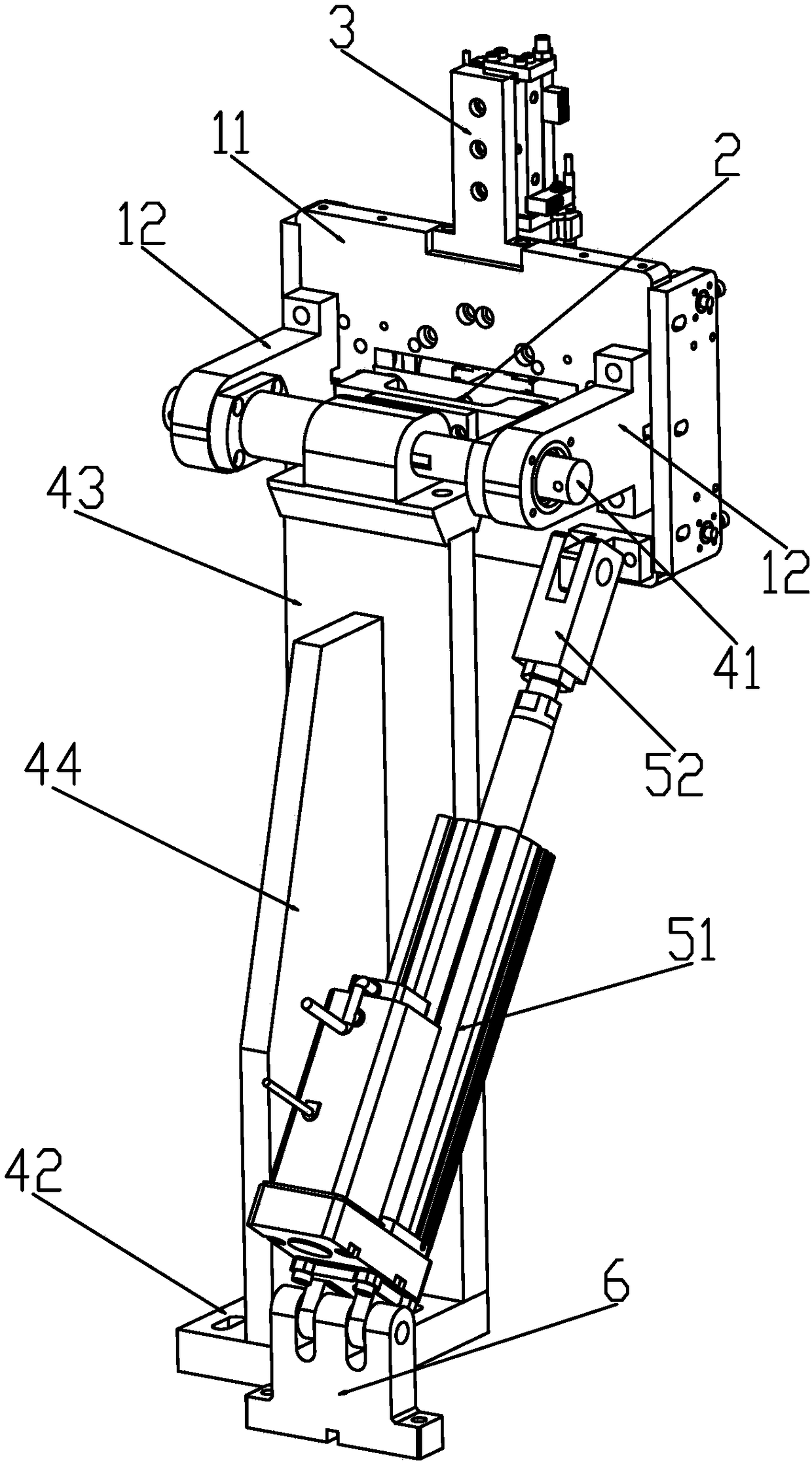

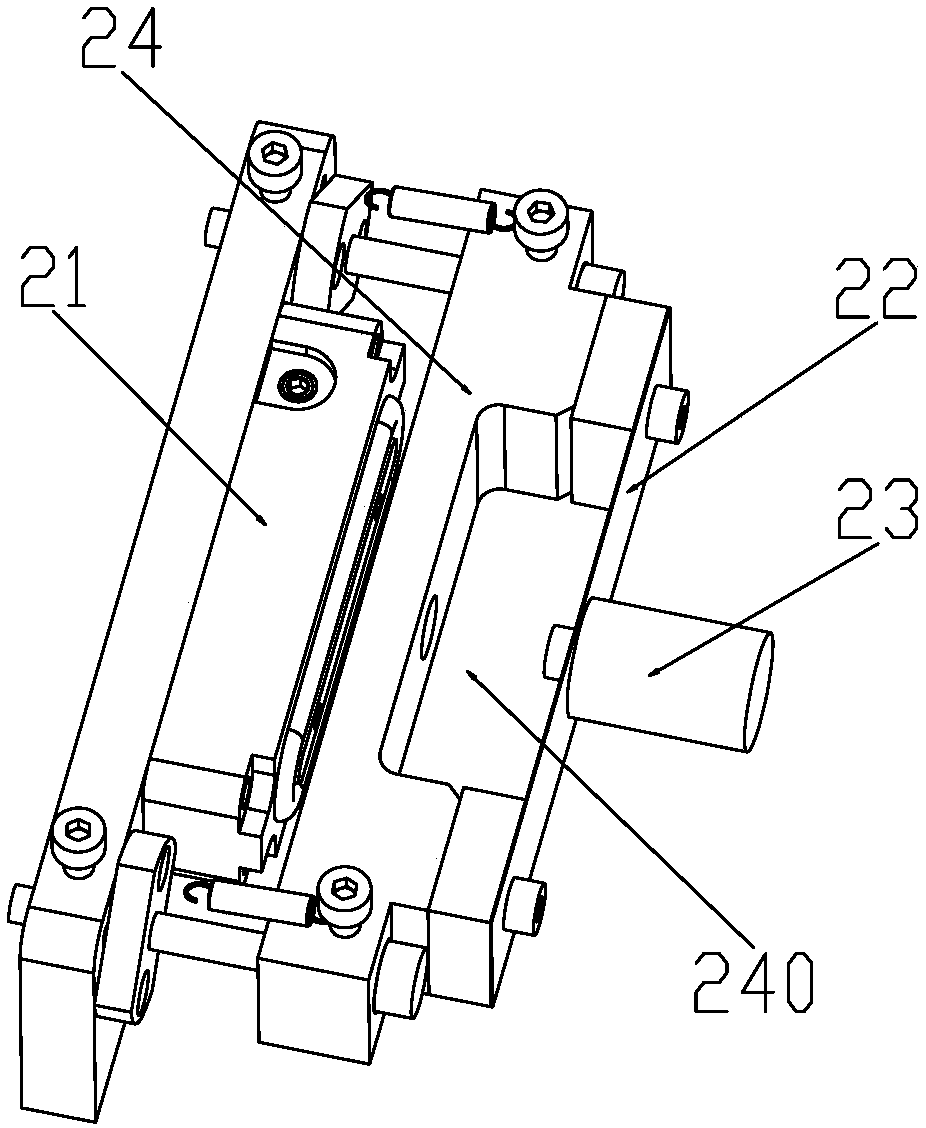

[0021] The following is attached Figures 1 to 5 The given examples further illustrate the specific implementation of the vibration and noise collection machine of the present invention. The vibration noise collection machine of the present invention is not limited to the description of the following embodiments.

[0022] Such as figure 1 with figure 2 As shown, the vibration noise collection machine of the present invention includes a mounting frame 1 for limiting the product A to be tested, a noise collection device 2 for collecting the vibration noise of the product A to be tested, and a communication device for the product A to be tested. The on-off device 3 for power-off, the noise collection device 2 is arranged opposite to the product A to be tested, the noise collection device 2 includes a shrapnel 22 and an acceleration sensor 23, and the acceleration sensor 23 is installed on the shrapnel 22, when collecting vibration noise The acceleration sensor 23 is in contac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com